Semiconductor device

A technology of semiconductor and conductor components, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., and can solve problems such as reduced heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

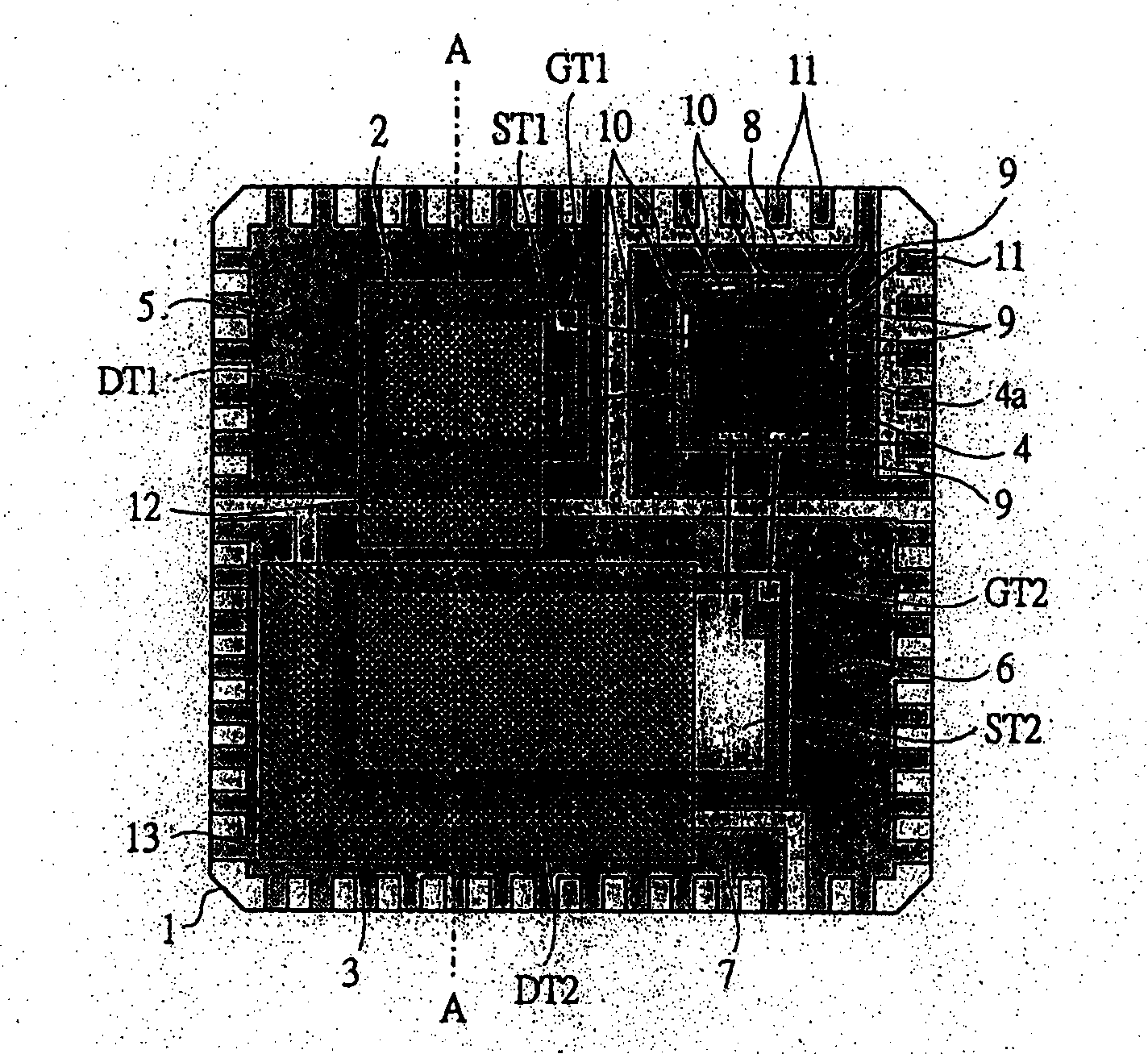

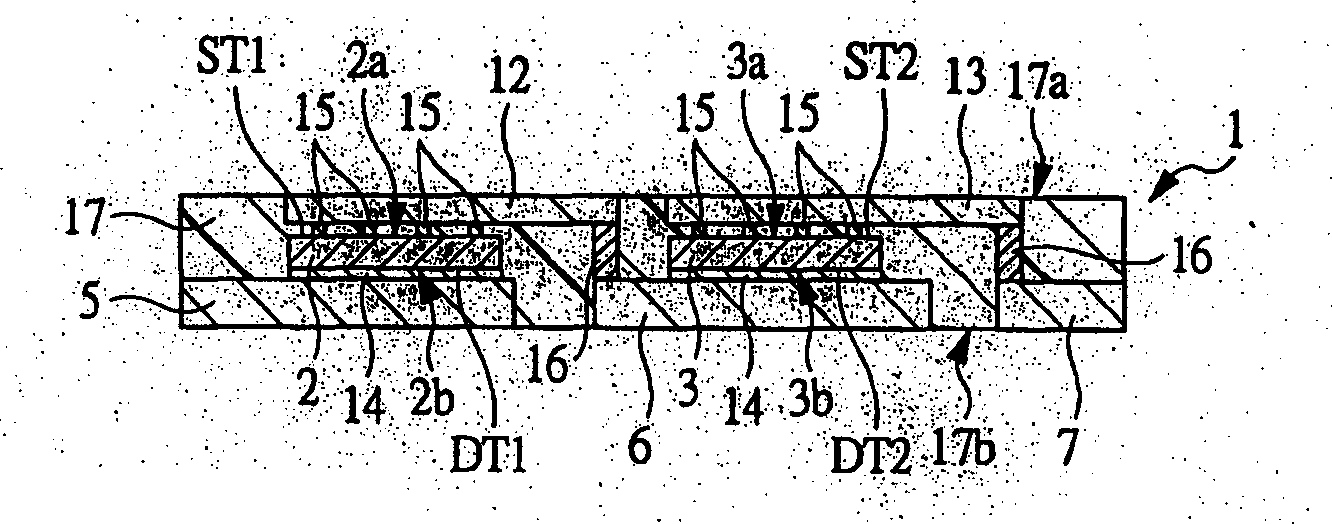

[0052] figure 1 It is a plan view showing an example of the structure of the semiconductor device (multi-chip module for non-isolated DC / DC converter) of Embodiment 1 of the present invention through a package, Figure 17 is through figure 1 The oblique view showing the interior of the semiconductor device shown in, figure 2 is shown along figure 1 A cross-sectional view of the structure of the cross-section cut by the line A-A shown in, image 3 is showing figure 1 The back view of the structure of the semiconductor device shown in, Figure 4 is showing figure 1 The external oblique view of the structure of the semiconductor device shown in, Figure 5 ~ Figure 7 are cross-sectional views each showing the structure of a semiconductor device according to a modified example of Embodiment 1 of the present invention, Figure 8 is showing figure 1 A circuit diagram of an example of an equivalent circuit when mounted in a semiconductor device (non-isolated DC / DC converter) ...

Embodiment 2

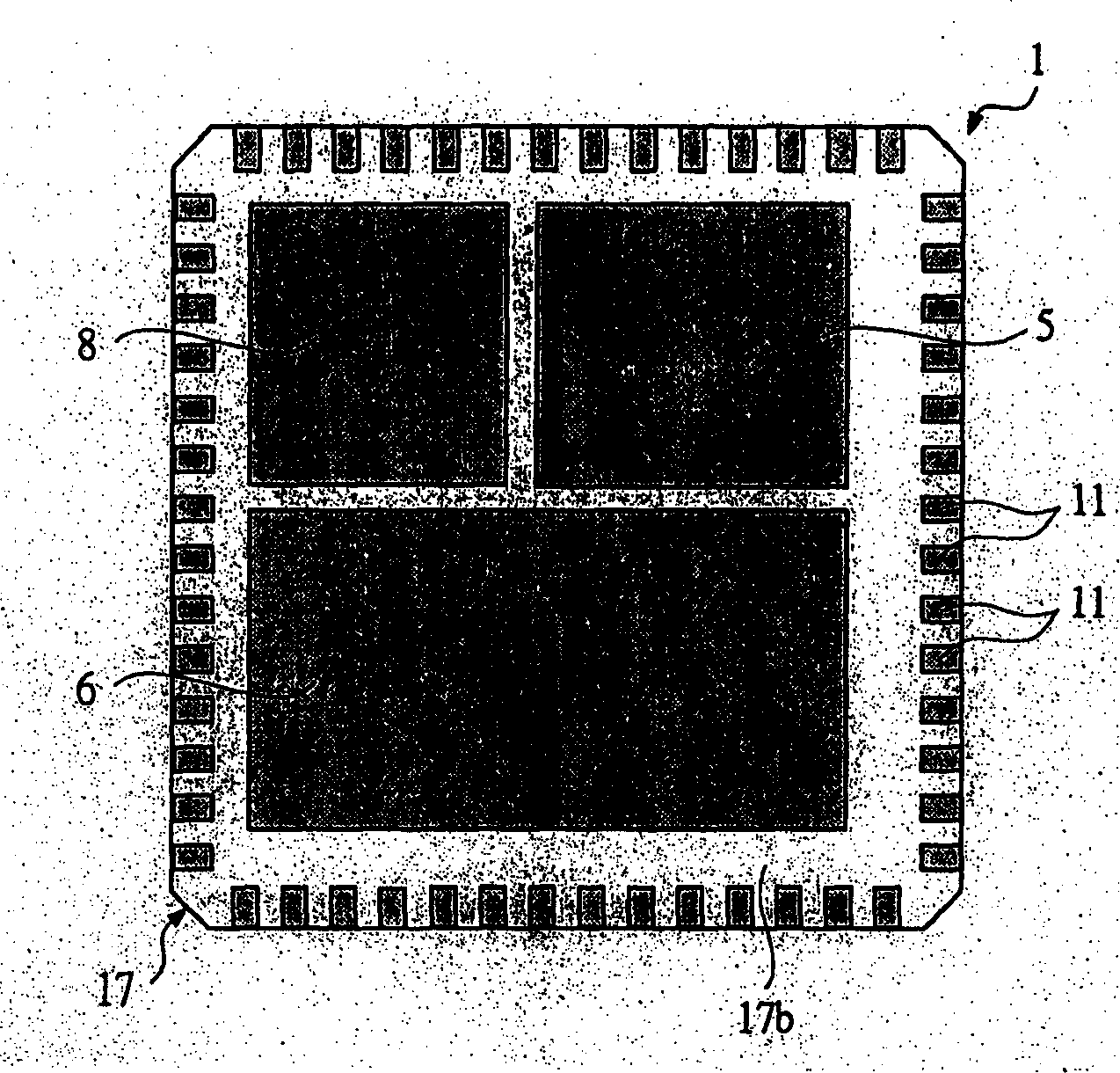

[0081] Figure 9 It is a plan view showing an example of the structure of the semiconductor device (multi-chip module for non-isolated DC / DC converter) of Embodiment 2 of the present invention through a package, Figure 10 is shown along Figure 9 A cross-sectional view of the structure of the cross-section cut along the line B-B shown in, Figure 11 is showing Figure 9 The back view of the structure of the semiconductor device shown in, Figure 12 is showing Figure 9 The external oblique view of the structure of the semiconductor device shown in .

[0082] The semiconductor device of present embodiment 2 is the same as embodiment 1, is the MCM (multi-chip module) 1 that the non-isolated type DC / DC converter is used, is to enclose the power MOSFET chip 2 for control, the power MOSFET chip 3 for synchronization and make it lead On / off driver IC chip 4 semiconductor package.

[0083] If explain the structure of the MCM1 of present embodiment 2, then as Figure 9 , Fig...

Embodiment 3

[0097] Figure 13 It is a cross-sectional view showing an example of the structure of the semiconductor device (multi-chip module for non-isolated DC / DC converter) of Embodiment 3 of the present invention, Figure 14 It is a cross-sectional view showing the structure of a semiconductor device according to a modified example of Embodiment 3 of the present invention.

[0098] The semiconductor device of the third embodiment is an MCM (multi-chip module) 1 for a non-isolated DC / DC converter, as in the first and second embodiments, and a structure for improving heat dissipation will be described.

[0099] Figure 13 In the MCM1 shown in , the heat sink 27 as a heat dissipation member is attached to the MCM1 described in Embodiment 1. That is, since the two plate-shaped lead parts (source plate-shaped lead parts 12 and 13) exposed on the surface 17a of the package 17 of the MCM1 of Example 1 have different potentials, the heat dissipation is installed via the insulating sheet 28....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com