Field emitting electronic source device and its preparing process

An electron source and field emission technology, which is used in the manufacture of electrical components, discharge tube electron guns, electrode systems, etc., can solve the problems of emission current divergence, difficulty in obtaining high-quality insulating layers, and difficulty in wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

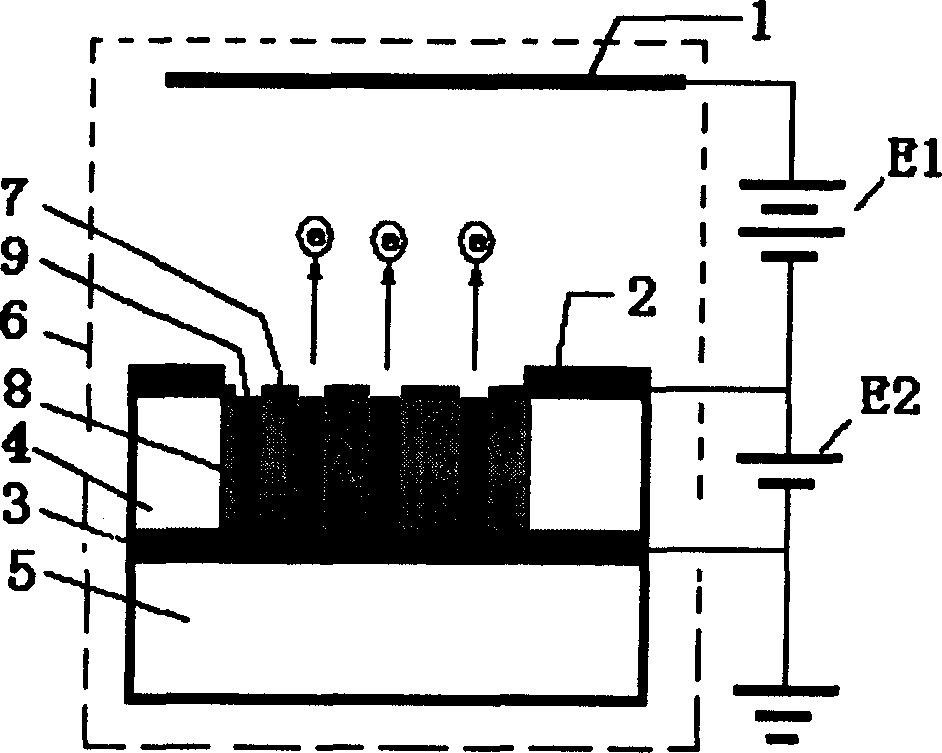

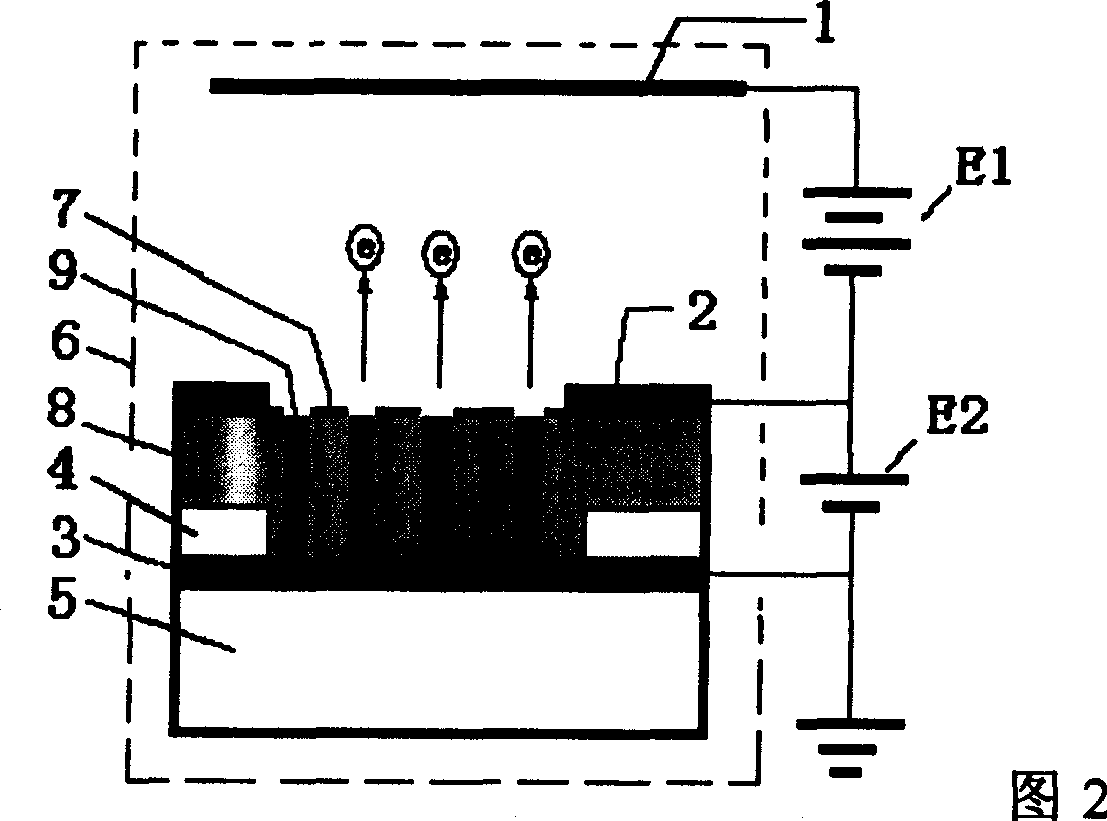

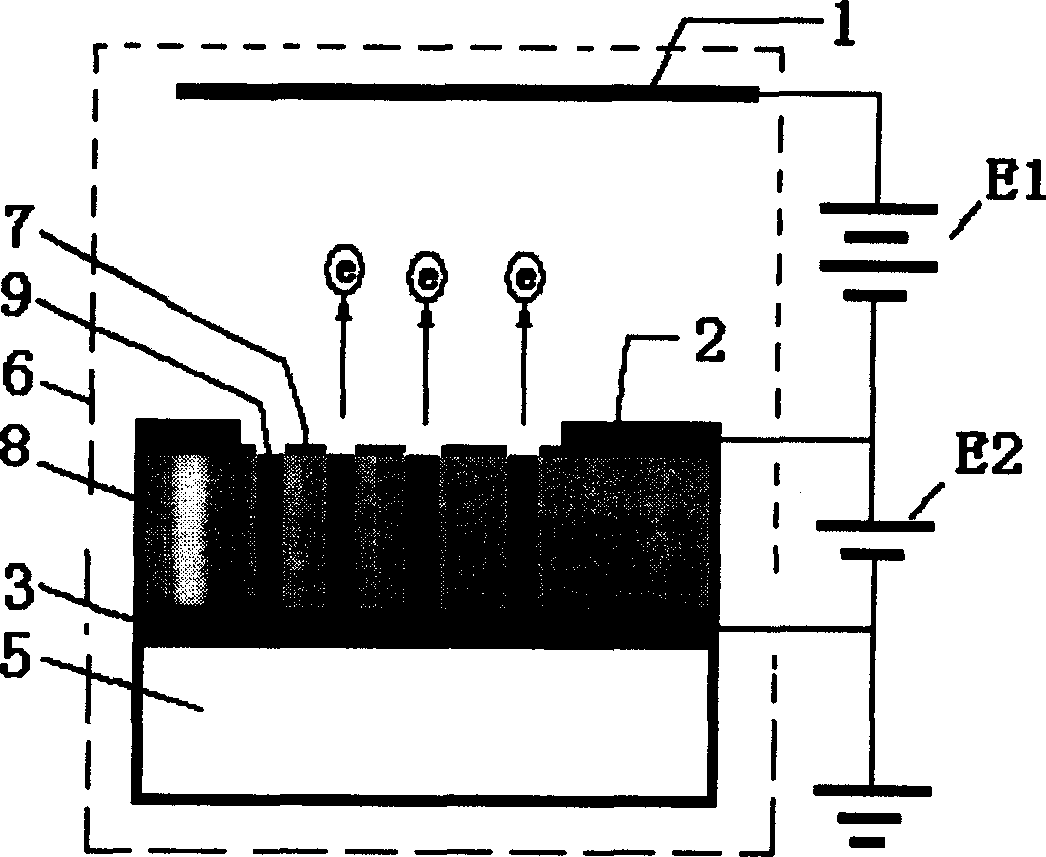

[0016] The present invention has an anode 1 sealed in a vacuum container 6 and a field emission electron source comprising a cathode 3 on a substrate 5 and a grid 2 and its interlayer structure. It is characterized in that the thick metal film (referred to as thick Metal film) and the cathode 3 is an insulating layer 4, and between the thin metal film 7 with a large number of micropores connected to the thick metal film and the cathode 3 is a complex layer 8, that is, the field emission electron source is the cathode 3 There is an insulating layer 4 on it, and a part of the insulating layer 4 is replaced by a complex layer 8, and a network-shaped thin metal film 7 with a large number of micropores is used as a part of the gate 2 on the composite layer 8. Such as figure 1 As shown, the thin metal film 7 is a metal film with a thickness within 50 nanometers and a large number of micropores with a pore diameter within 1 micron as the electrode of the gate 2, so as to technically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com