Dual-component automatic spray painting device

A two-component, filter device technology, applied in the direction of spray device, liquid spray device, etc., can solve the problems of complicated structure of spray gun, inconvenient to assemble, disassemble, clean or replace, and insufficient mixing of two-component materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present invention can be made by mechanical manufacturing method and plastic blow molding or injection molding method, but the whole device system should be made according to the pressurized system, and the making and installation of the spray gun and parts should be accurately matched.

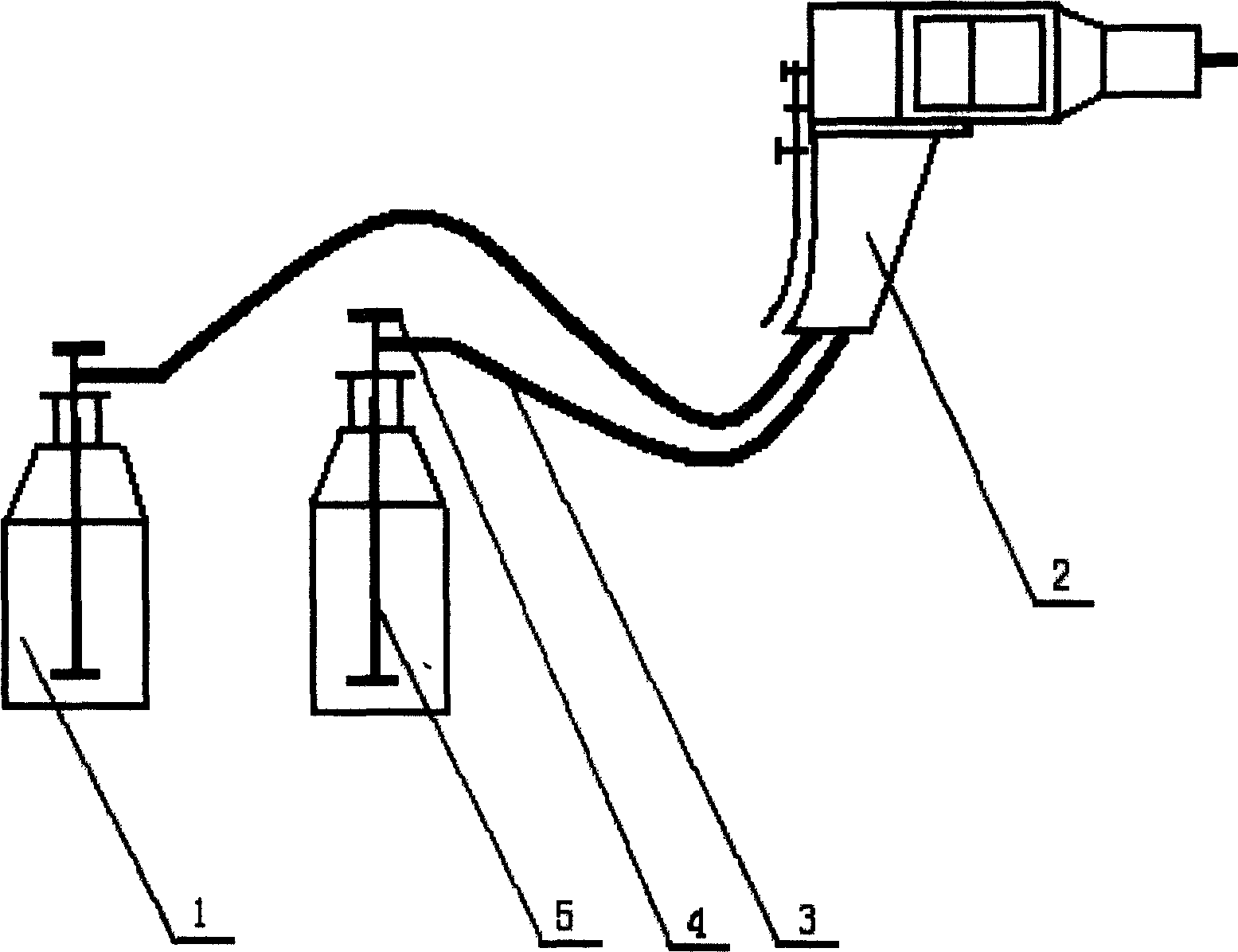

[0024] figure 1 Among them, the device of the present invention includes two metal material storage tanks (1), and a material guide valve (4) is connected by bolts on the storage tank top cover of the material storage tank (1). The material guide valve (4) is recommended to use "Ningbo The needle valve of model YSF-1” produced by Wan’an Valve Factory is threadedly connected with the feed pipe (5) in the tank at one end of the feed valve (4), and the other end is provided with a soft seal with a nut seal interface. The feed pipe (3) is connected and connected to the spray gun (2).

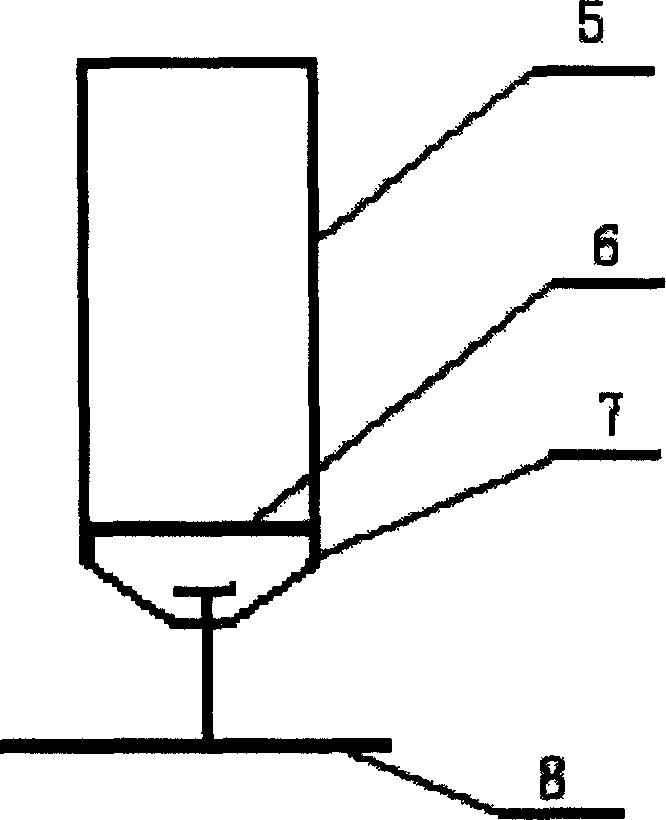

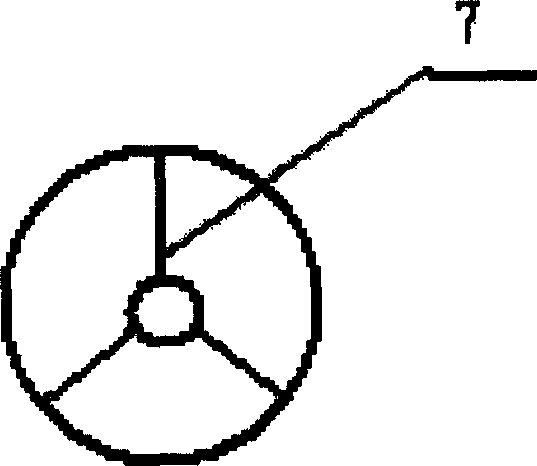

[0025] The main structure in the whole device is: in the material storage tank (1) is provided with th...

Embodiment 2

[0032] According to the preparation method and the use method of embodiment 1, if gaps such as coal mine roadways and mining areas are filled and plugged, the material storage tank (1) should be charged or injected with 3~5Kg of polyurethane elastic prepolymer and three Vinyl chloride solvent 0.5~2.5MP a , the other material storage tank (1) is filled or injected with 0.5-2Kg of diamine or glycol cross-linking agent, and the pressure is 1.5-2.5MP a , when spraying, open the material guide valve (4), and then open the first feed bin inlet pipe control valve (15) and the second feed bin inlet pipe control valve (16) on the handle of the spray gun to adjust the material ratio, and then Regulate the size of the spraying amount, then press the spray gun switch handle (41), and the gap in the mine can be filled and plugged.

Embodiment 3

[0034] According to the production method and usage method of Example 1, if a temporary thermal insulation tent is set up in the rescue and disaster relief process, it can be charged or injected into the material storage tank (1) with MDI: 5-10kg, aerosol (monochlorodifluoro Methane): 0.5~1.0kg, pressure: 1.5~2.5MP a ; In the other material storage tank (1), rush into the spraying combination polyether; 4~8kg, aerosol (chlorodifluoromethane): 2~3kg, pressure: 1.5~2.5MP a , Spraying on straw mats, woven tapes, canvas, etc. as the base material frame can quickly establish a temporary tent for cold insulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com