Plane glass ceramic object having at least one dull polishing region and its preparing method

A glass-ceramic, frosted technology, applied in glass manufacturing equipment, glass forming, heating methods, etc., can solve the problem that the coating is only suitable for holding, and achieve the effect of a simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

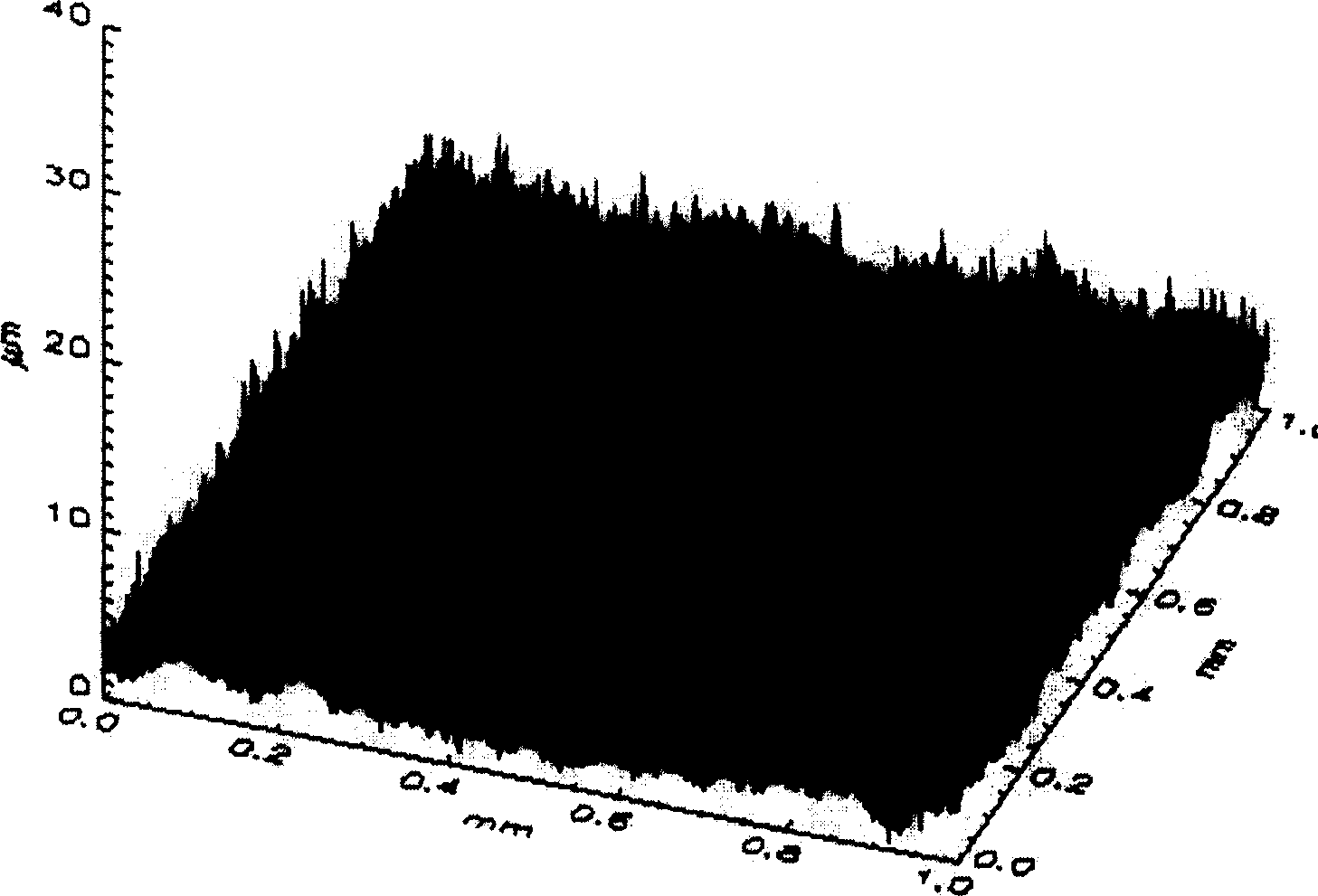

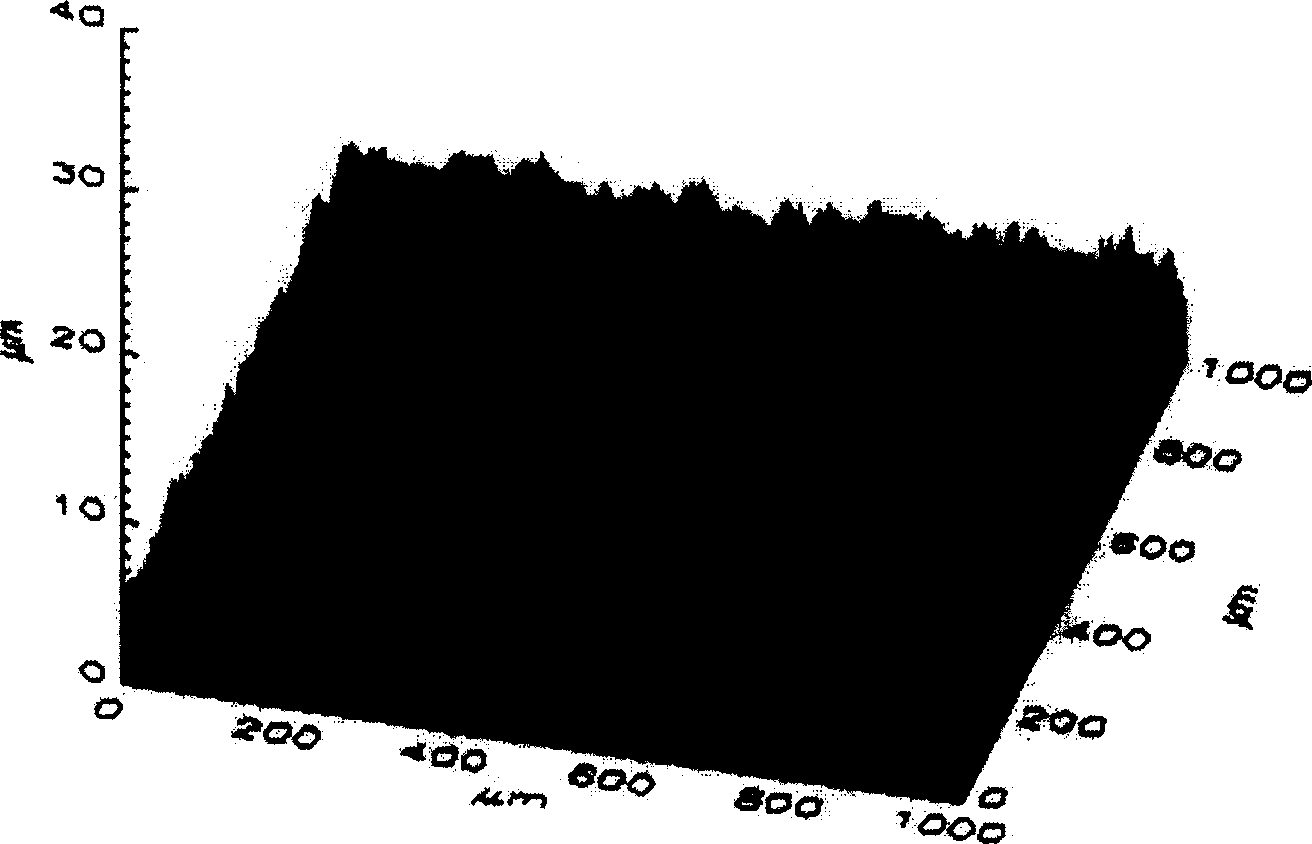

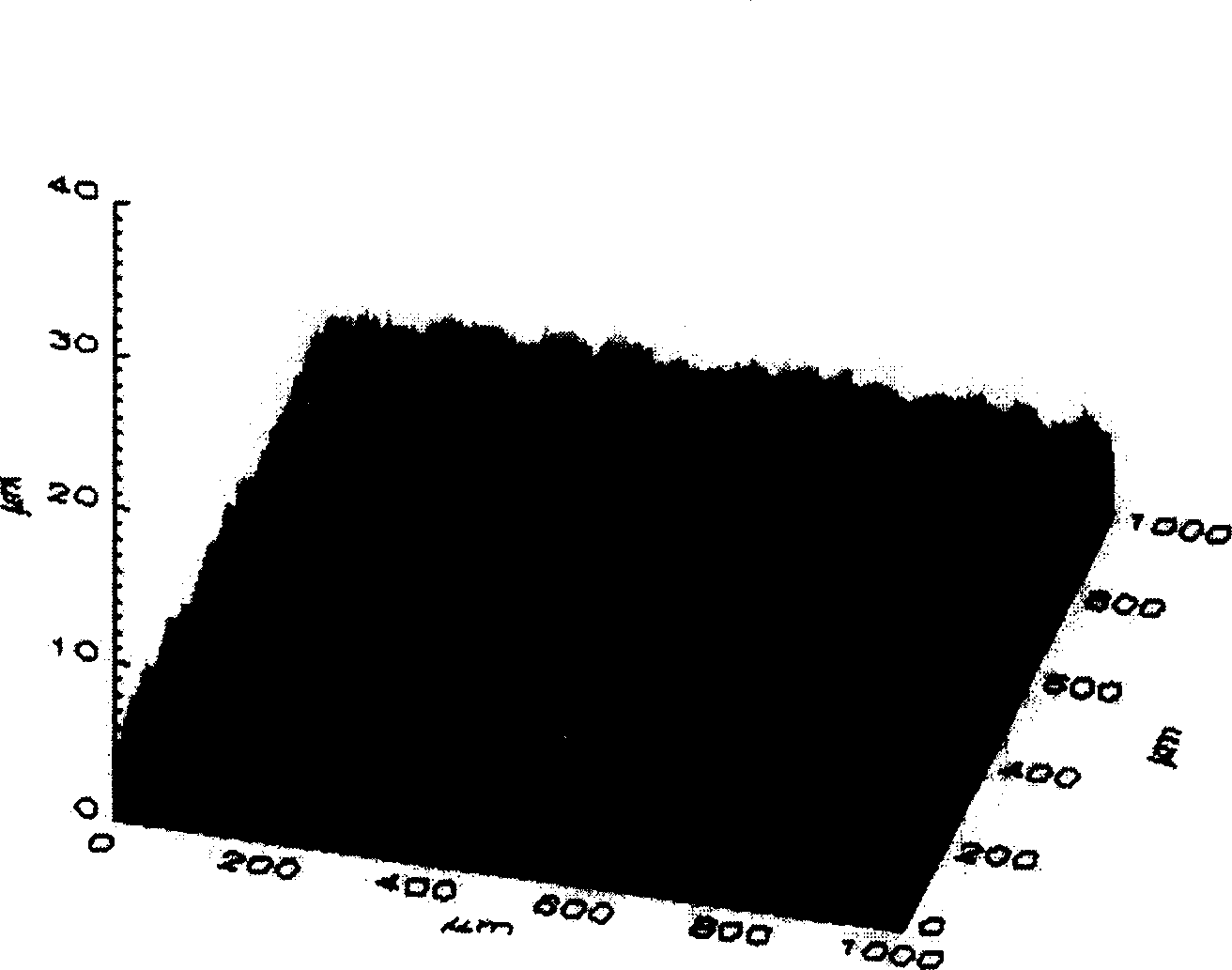

Image

Examples

Embodiment

[0033] Black glass-ceramic (designation CERANHIGHTRANS) described in DE 19721737 C1 , and described in EP 0220333 B1) on plate-like substrates in a non-ceramic state, ie in the corresponding blank glass matrix, are screen-printed by a usual screen-printing medium based on aromatic hydrocarbon mixtures ( Such as Zschimmer&Schwarz GmbH & Co.KG Chemische Fabriken products) and the grade is BOROFLOAT 3.3 Paste composed of borosilicate glass. The paste ratio is 10 parts by weight of glass frit and 12 parts by weight of screen printing medium. The mesh of the screen was 36 μm.

[0034] The data of glass powder are as follows:

[0035] Oxide

Weight % (±0.3)

SiO 2

80.9

B 2 o 3

12.8

Na 2 o

3.3

K 2 o

0.6

Al 2 o 3

2.4

[0036] Clarifying agent: NaCl

[0037] Granularity

pulp

D10[μm]

0.4

0.4

D50[μm]

0.9

0.9

D99[μm]

2.6

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com