Preparation method of supported catalyst for synthesizing vinyl acetate

A technology of supported catalyst and vinyl acetate, which is applied in the field of preparation of supported catalysts and can solve problems such as loss of catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

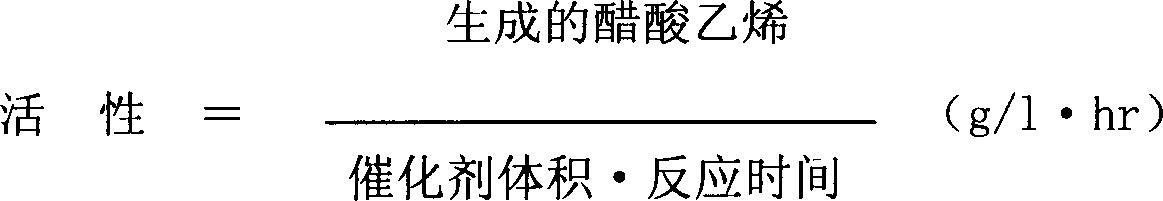

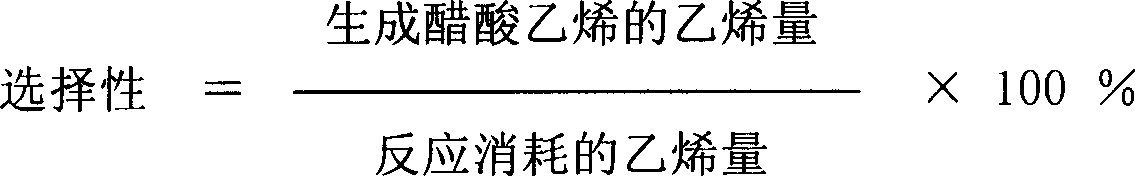

Method used

Image

Examples

Embodiment 1~4

[0040] Take 1.1 liters of spherical silica carrier (particle size 4-6mm), and use 2.92 grams of CuCl 2 2H 2 Soak in 450 ml of aqueous O solution for 1 hour at room temperature.

[0041] 7.32g of sodium silicate nonahydrate was made into 100ml of aqueous solution and added to the above-mentioned carrier, shaken several times to avoid agglomeration, and then stood still for 24 hours.

[0042] 10 ml of hydrazine hydrate with a concentration of 85 wt % was used to impregnate the carrier for reduction, and the impregnation time was 5 hours.

[0043] The catalyst precursor was washed with deionized water until the effluent did not contain chloride ions (checked with silver nitrate), and then dried at 60° C. to obtain the catalyst precursor.

[0044] The catalyst precursor is calcined under an inert or reducing atmosphere, and the specific calcining conditions of each embodiment are shown in Table 1.

[0045] with 4.21 g of H 2 PdCl 4 and 2.04 g HAuCl 4 450 milliliters of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com