Horizontal double-layer grate back firing boiler

A double-layer furnace and boiler technology, applied in the field of horizontal boilers, can solve the problems of environmental pollution, high exhaust gas temperature, heat loss, etc., and achieve the effects of reducing pollution, reducing exhaust gas temperature, reducing exhaust gas temperature and smoke content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

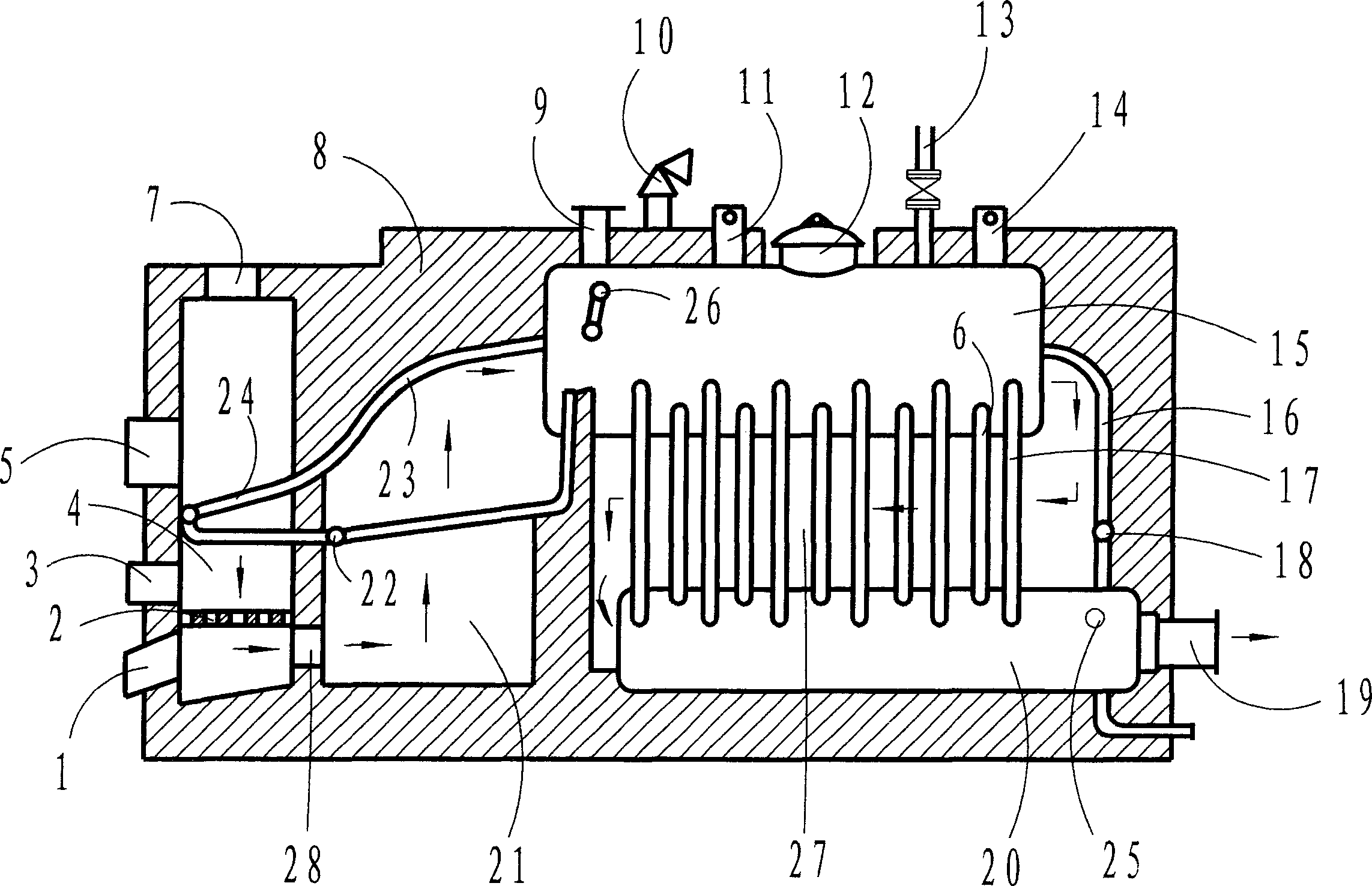

[0017] See attached picture. The serial numbers in the figure represent: slagging outlet 1, cast iron grate 2, fire door 3, combustion chamber 4, furnace door 5, convection pipe 6, air inlet 7, furnace wall 8, pressure gauge connection 9, safety valve connection 10 , lifting rings 11, 14, cold hole 12, main steam valve 13, drum 15, rear shed pipe 16, water wall pipe 17, rear header 18, smoke outlet pipe 19, tube heat exchanger 20, high temperature smoke chamber 21 , The front header 22, the front shed pipe 23, the water pipe grate 24, the water inlet 25, the water level gauge 26, the heat exchange chamber 27, the smoke inlet 28, and the arrow indicates the flow direction of the smoke.

[0018] The structure of the horizontal double-layer grate reverse combustion boiler in the embodiment of the present invention consists of a drum 15, a tube heat exchanger 20, a water-cooled wall tube 17, a downcomer (drawn at the end of the figure), a convection tube 6, and a front shed tube. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com