Exhaust gas purifying device for engine

An exhaust gas purification and engine technology, which is applied in mechanical equipment, engine components, engine control, etc., can solve the problems of excessive temperature rise of catalysts, dependence on timing pulses, inability to achieve sulfur purification temperature, etc., and achieve the effect of preventing excessive temperature rise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

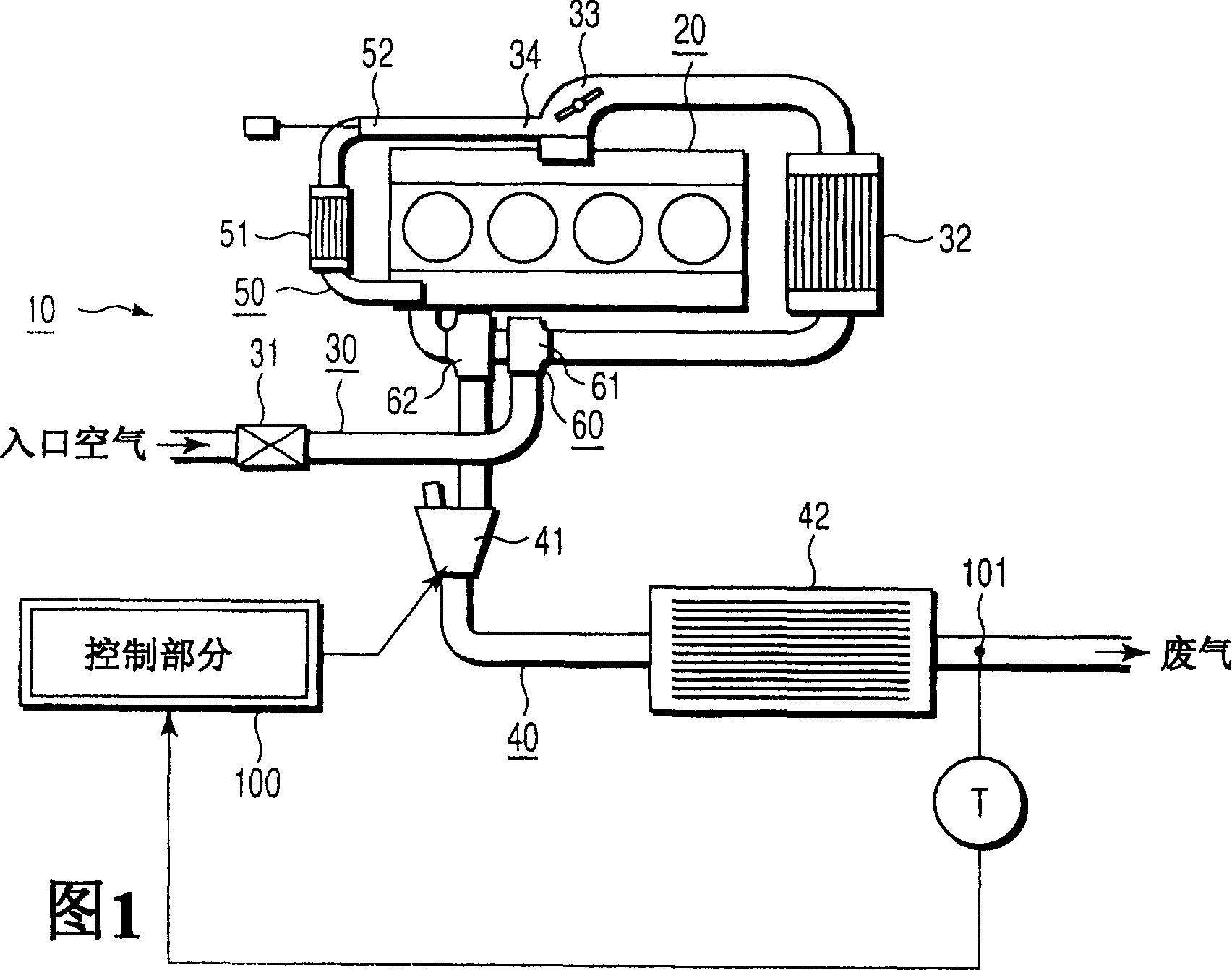

[0020] 1 is a schematic diagram showing the structure of an engine exhaust gas purification device 10 according to an embodiment of the present invention;

[0021] Engine system 10 includes a diesel engine 20 . The diesel engine 20 is connected to an intake pipe 30 on its intake side and to an exhaust pipe 40 on its exhaust side. Also, the exhaust port side of the diesel engine 20 is connected to the intake pipe 30 through an EGR duct 50 that circulates exhaust gas (EGR gas) into the intake pipe 30 . Reference numeral 60 in FIG. 3 denotes a supercharger and reference numeral 100 denotes a control unit.

[0022] In order from the intake port side, the intake pipe 30 is provided with an air flow sensor 30 , a compressor 61 of a supercharger 60 , an intercooler 32 , an intake throttle valve 33 , and a connection portion corresponding to the EGR duct 50 34.

[0023] In order from the diesel engine 20 side, the exhaust pipe 40 is provided with the turbine 62 of the supercharger ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com