Smoke desulfuring, denitrating and integrating apparatus with impulsing corona discharge

A pulsed corona, desulfurization and denitration technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., to reduce costs, reduce energy consumption, and enhance stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

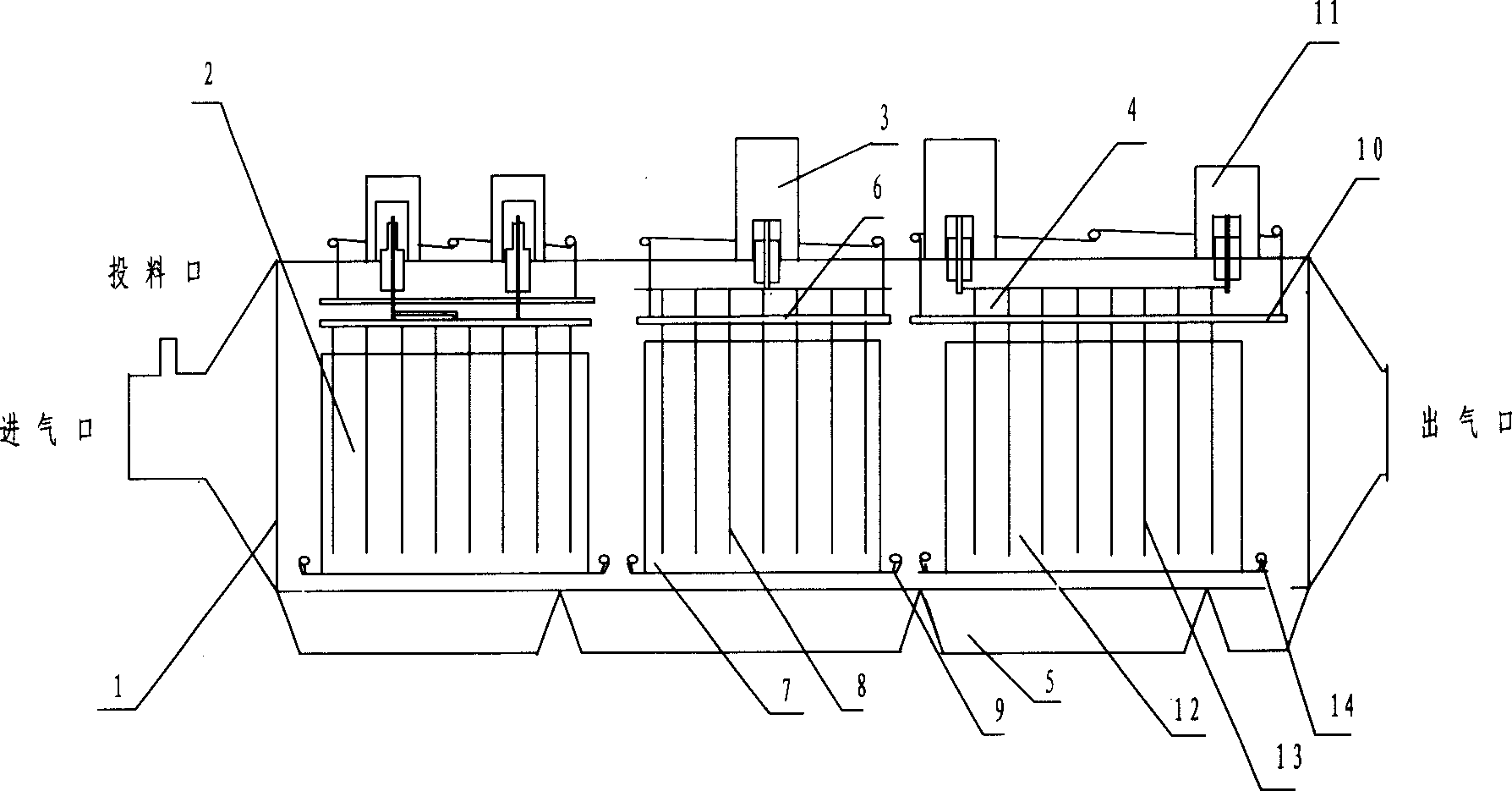

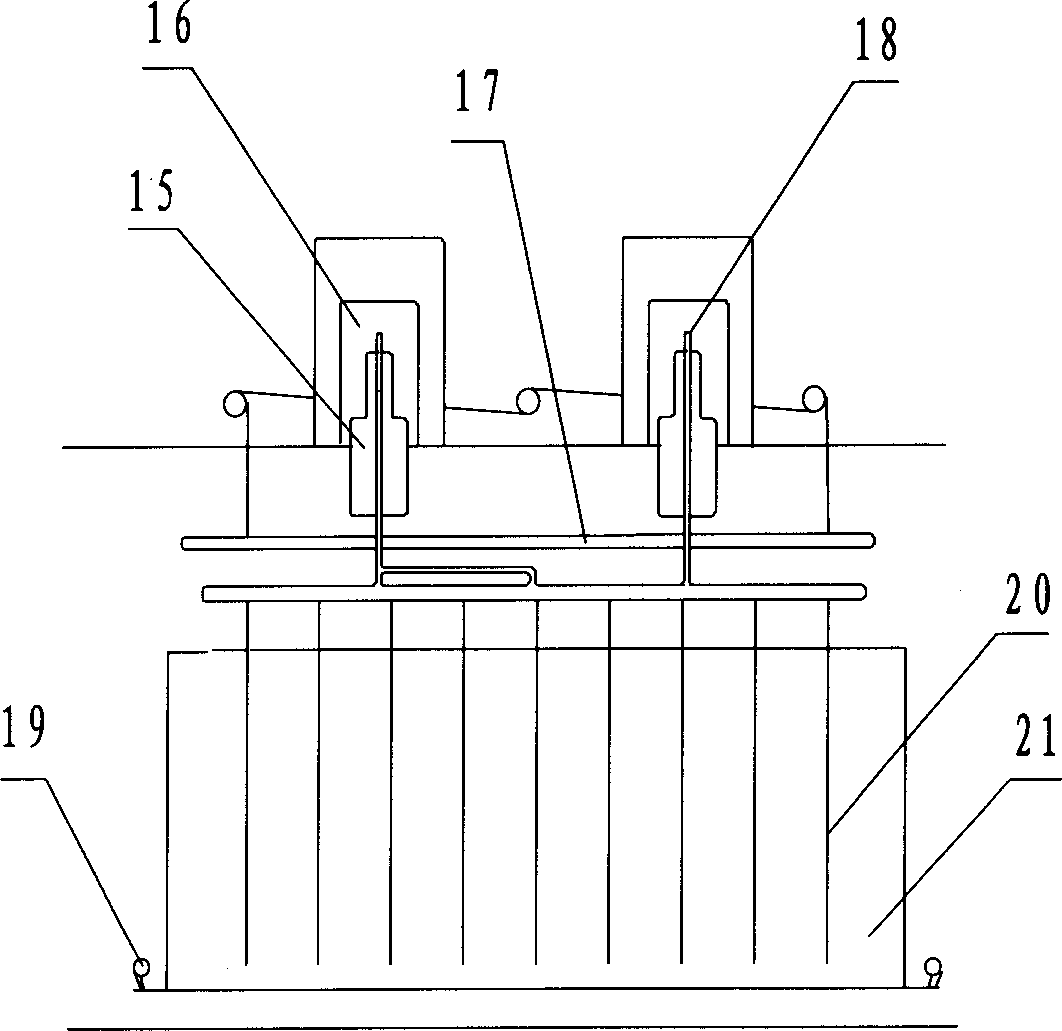

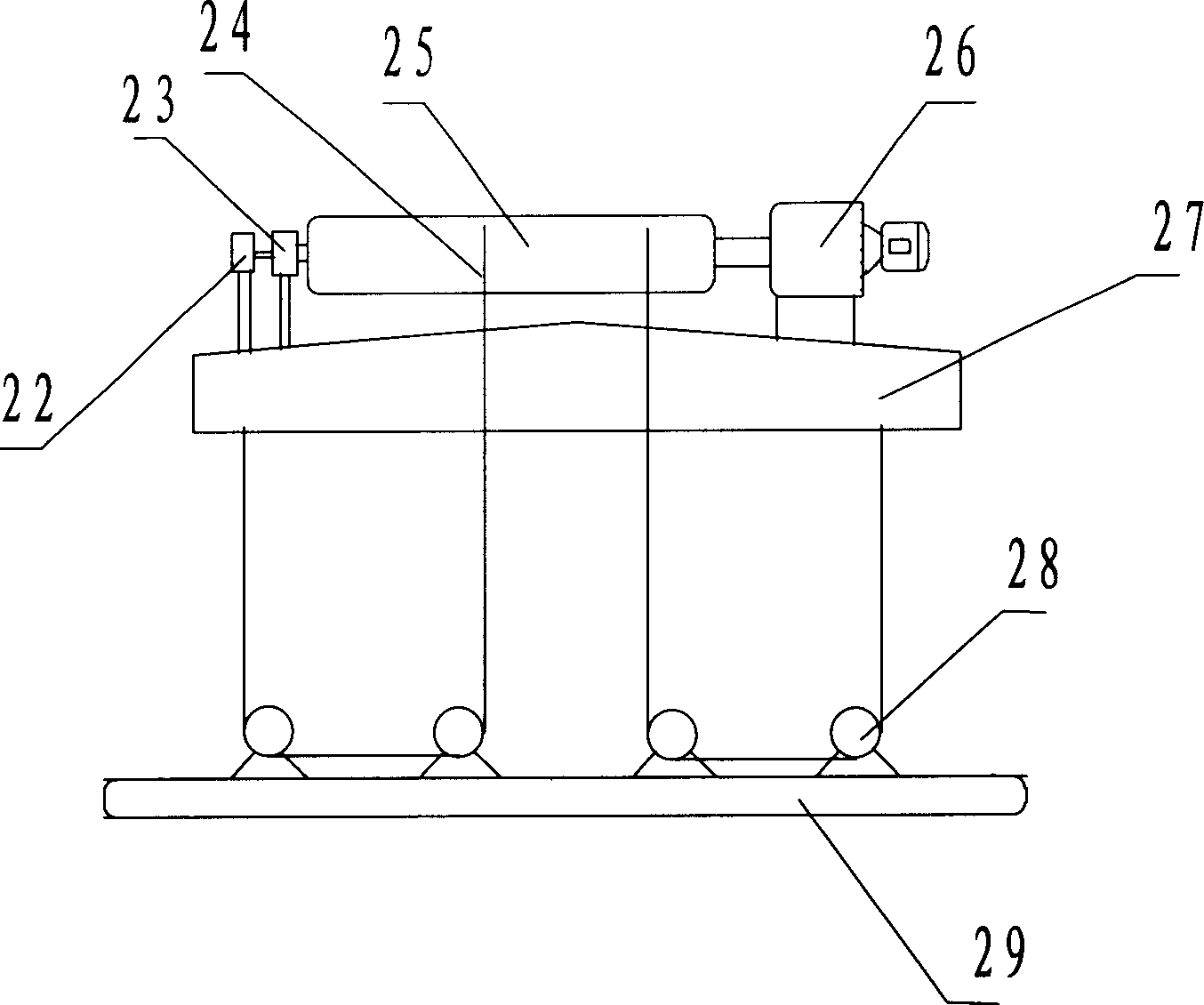

[0032] The pulse corona discharge flue gas desulfurization, denitrification, reaction and dust removal integrated device of the present invention includes a gaseous hydrocarbon gas dosing unit for improving the removal rate of nitrogen oxides, and an air distribution plate unit 1 for adjusting the flow direction and flow rate stability. , Water vapor ammonia activation unit 2 for water vapor ammonia activation, pulsed corona unit 3 for generating active radicals and ions, by-product collection unit 4 for by-product collection. The integrated device is respectively provided with an air inlet, a feeding port, and an air outlet; the integrated device is provided with an air distribution plate unit 1, a water vapor ammonia activation unit 2, a pulse corona unit 3, and a by-product collection unit. 4. The gaseous hydrocarbon gas dosing unit is arranged outside the integrated device and connected to the feeding port; the ash hopper 5 is arranged at the lower part of the integrated de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com