Precisive measurement of static knife profile

A precision measurement and tool technology, which is used in measurement/indication equipment, manufacturing tools, metal processing machinery parts, etc., can solve the problems of poor accuracy of gray-moment edge detection algorithm, large amount of calculation, noise sensitivity, etc., to achieve simple operation, The effect of strong anti-noise ability and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

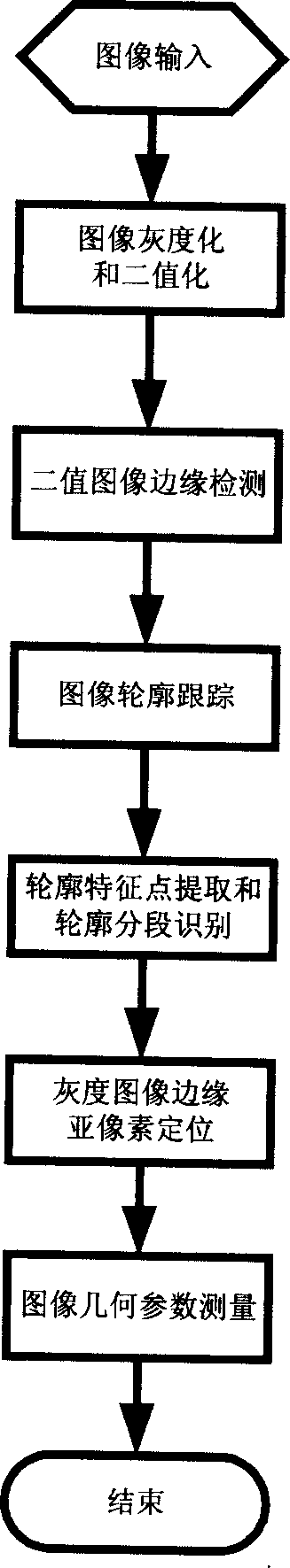

[0059] To accurately measure a tool, follow the steps below:

[0060] 1. Use a digital camera to take a color tool image, input the tool image into the computer through the USB interface, and convert it into a grayscale image and a binary image, such as Figure 4 shown.

[0061] 2. Perform morphological filtering on the binary image of the tool, and a series of preprocessing of gradient, thinning, and pruning to obtain the rough edge of the binary image of the tool, such as Figure 5 (a) shown.

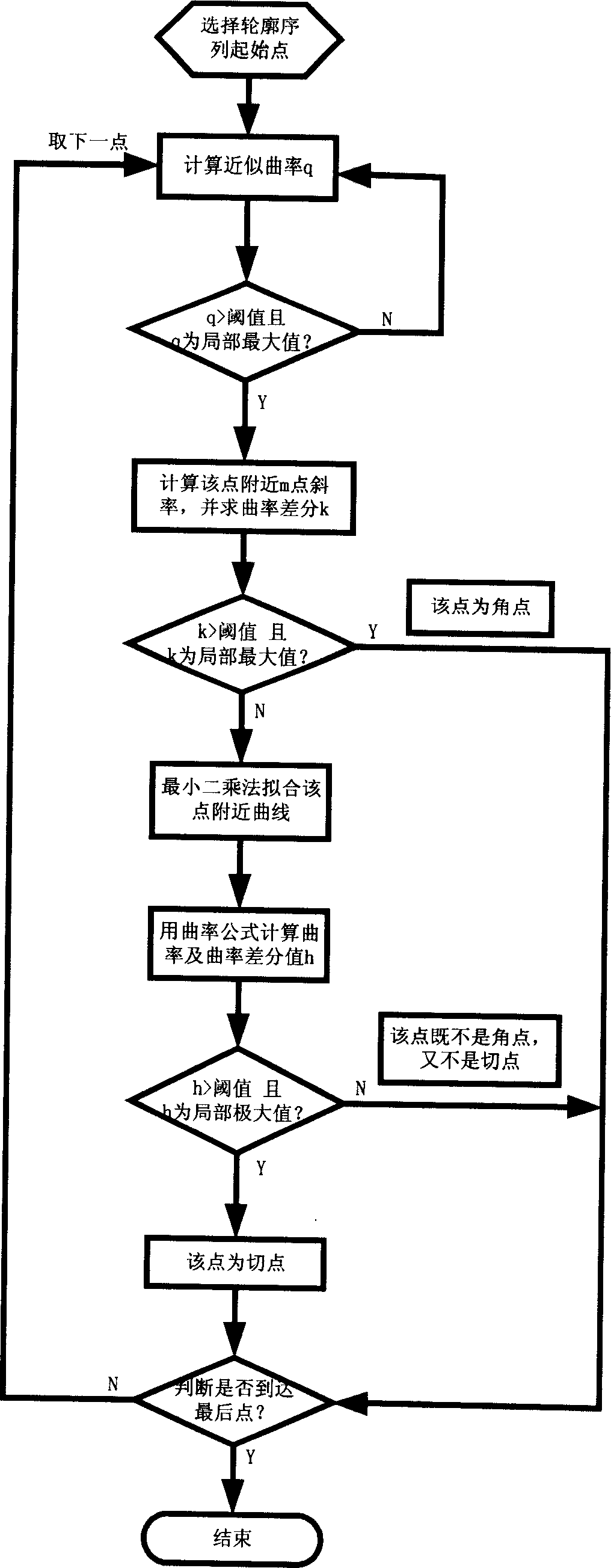

[0062] 3. Perform contour tracking on the edge of the binary image of the tool, and extract the feature points of the image contour of the tool, and then perform segmental recognition of straight lines and arcs on the contour of the binary image of the tool.

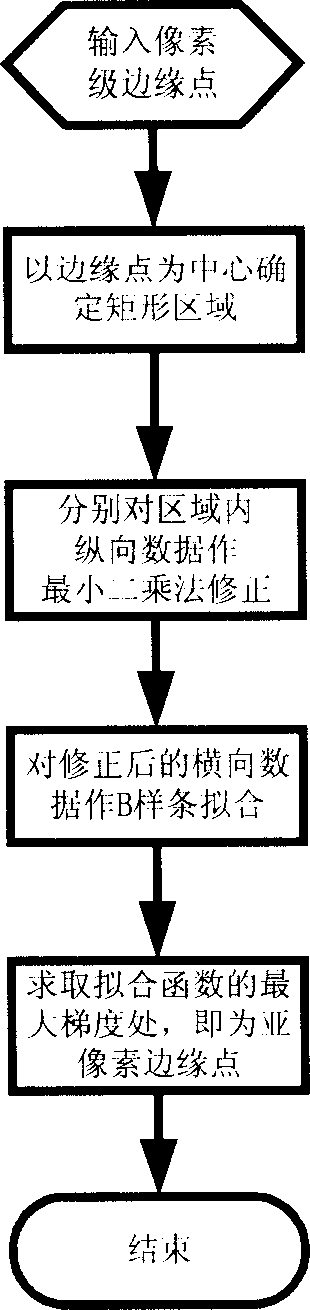

[0063] 4. Use the B-spline curve fitting method to locate the edge of the gray image of the tool by sub-pixel.

[0064] 5. Utilize the geometric relationship of the edge of the tool image to calculate high-precision tool geome...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com