Compounds useful in the manufacture of an anti-inflammatory androstane derivative

A compound and product technology, applied in the field of treatment of inflammatory diseases and allergic diseases, can solve the problems of difficult understanding of pharmacodynamics and pharmacokinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

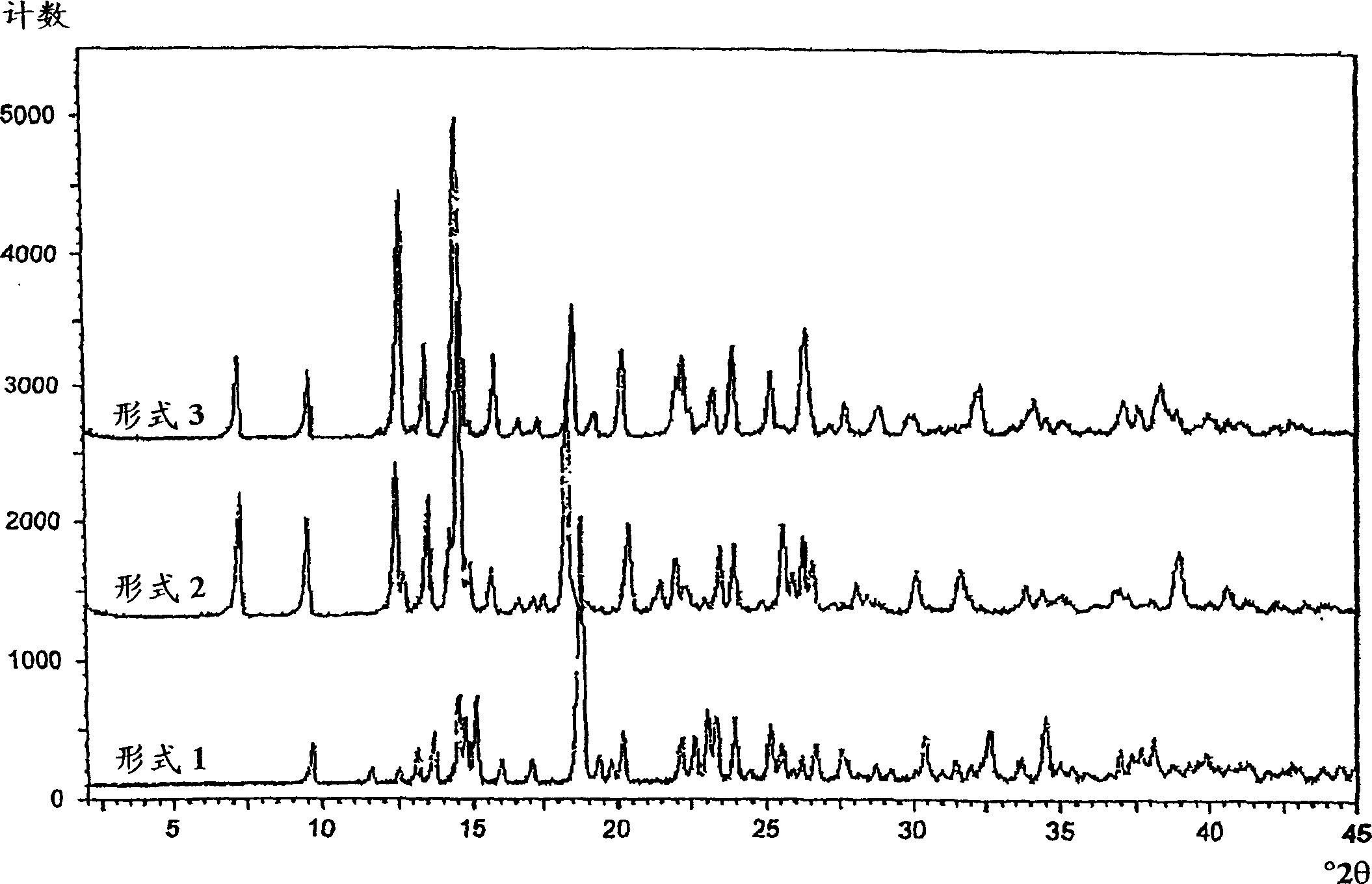

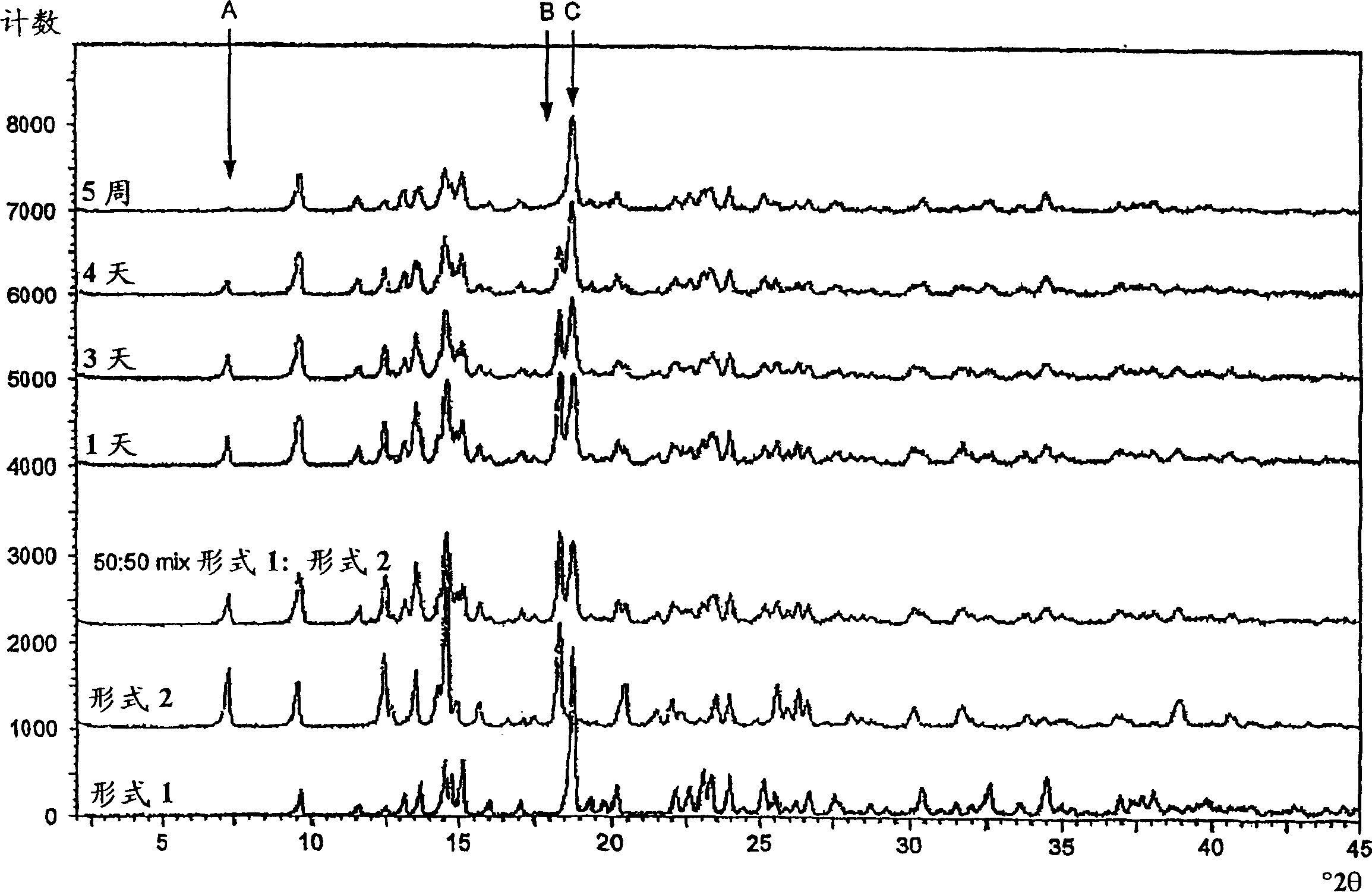

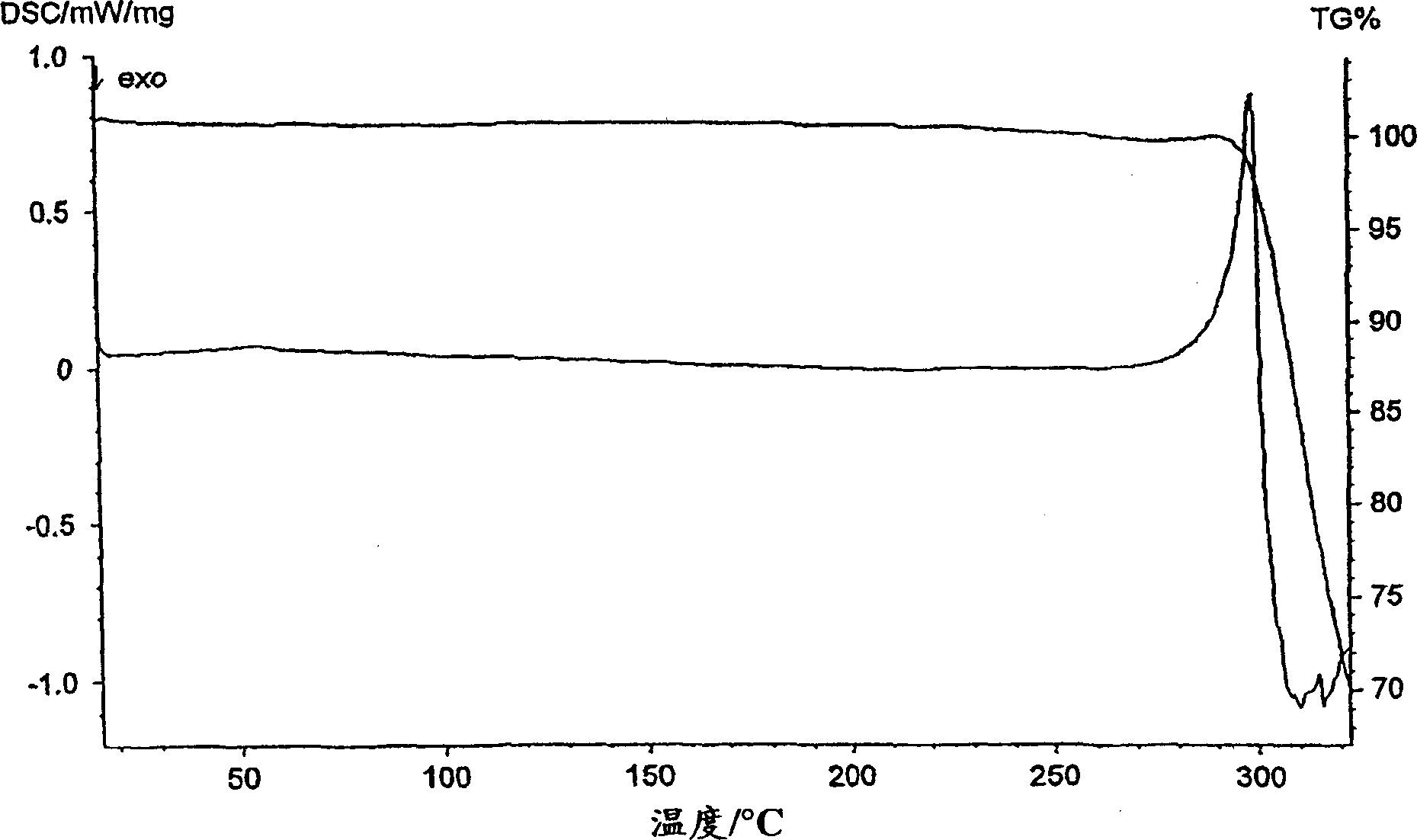

[0238] Example 1: 6α,9α-difluoro-17α-[(2-furylcarbonyl)oxy]-11β-hydroxy-16α-methyl- 3-Oxo-androst-1,4-diene-17β-thiocarboxylate S-fluoromethyl ester unsolvated form 1

[0239] A suspension of Intermediate 1 (2.5 g, 4.94 mmol) was dissolved in dry N,N-dimethylformamide (25 ml) and sodium bicarbonate (465 mg, 5.53 mmol) was added. The mixture was stirred at -20°C and bromofluoromethane (0.77ml, 6.37mmol) was added and the mixture was stirred at -20°C for 2 hours. Diethylamine (2.57ml, 24.7mmol) was added and the mixture was stirred at -20°C for 30 minutes. The mixture was added to 2M hydrochloric acid (93ml) and stirred for 30 minutes. Water (300ml) was added and the precipitate was collected by filtration, washed with water and dried in vacuo at 50°C to give a white solid which was recrystallized from acetone / water (to give 6α,9α-difluoro-17α-[( 2-furylcarbonyl)oxy]-11β-hydroxy-16α-methyl-3-oxo-androst-1,4-diene-17β-thiocarboxylate S-fluoromethyl ester) and at 50 Drying ...

Embodiment 2

[0268] Example 2: 6α,9α-difluoro-17α-[(2-furylcarbonyl)oxy]-11β-hydroxy-16α-methyl- 3-Oxo-androst-1,4-diene-17β-thiocarboxylate S-fluoromethyl ester

[0269] Unsolvated form 2

[0270] 6α,9α-Difluoro-17α-[(2-furylcarbonyl)oxy]-11β-hydroxy-16α-methyl-3-oxo-androst-1,4-diene-17β-thio A suspension of S-fluoromethyl carboxylate (prepared eg according to the first method of Example 1) (6.0 g) in dichloromethane (180 ml) was heated to reflux to give a bright solution. The solution was clarified by hot filtration (Whatman 54 filter paper) and the solution was distilled at atmospheric pressure (ca. 100 ml of solvent collected), giving crystallization at reflux. The mixture was kept at reflux for about 30 minutes and cooled slowly to ambient temperature. The mixture was further cooled and aged at 10-20°C for 2 hours. The slurry was cooled below 10°C and the product was filtered off, absorbed dry and dried under vacuum at about 60°C overnight to give a white solid (4.34 g, 71%)...

Embodiment 3

[0273] Example 3: 6α,9α-difluoro-17α-[(2-furylcarbonyl)oxy]-11β-hydroxy-16α-methyl- 3-Oxo-androst-1,4-diene-17β-thiocarboxylate S-fluoromethyl ester

[0274] Unsolvated form 3

[0275] 6α,9α-Difluoro-17α-[(2-furylcarbonyl)oxy]-11β-hydroxy-16α-methyl-3-oxo-androst-1,4-diene-17β-thio A suspension of carboxylic acid S-fluoromethyl ester acetone solvate (prepared as in Example 11) (20.0 g) in dichloromethane (800 ml, 40 vol) and water (10 ml, 0.5 vol) was heated to reflux, A bright solution was obtained. The solution was clarified by hot filtration (Whatman 54 filter paper), during which time some solid crystallized in the filtrate, which was fully dissolved by heating to reflux. The solution was distilled at atmospheric pressure (about 400 ml of solvent collected) and allowed to cool to ambient temperature. The mixture was further cooled and aged at <10°C for 10 minutes. The product was filtered, absorbed dry and dried under vacuum at about 60°C overnight to give a whit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com