Sample-analyzing device and process for manufacturing the same

A technology for inspection devices and samples, which is applied in the direction of measuring devices, chemical instruments and methods, biochemical equipment and methods, etc., can solve the problems of large reaction field, low detection accuracy, inability to form hybrids efficiently, and achieve the realization of Miniaturization and analysis of the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

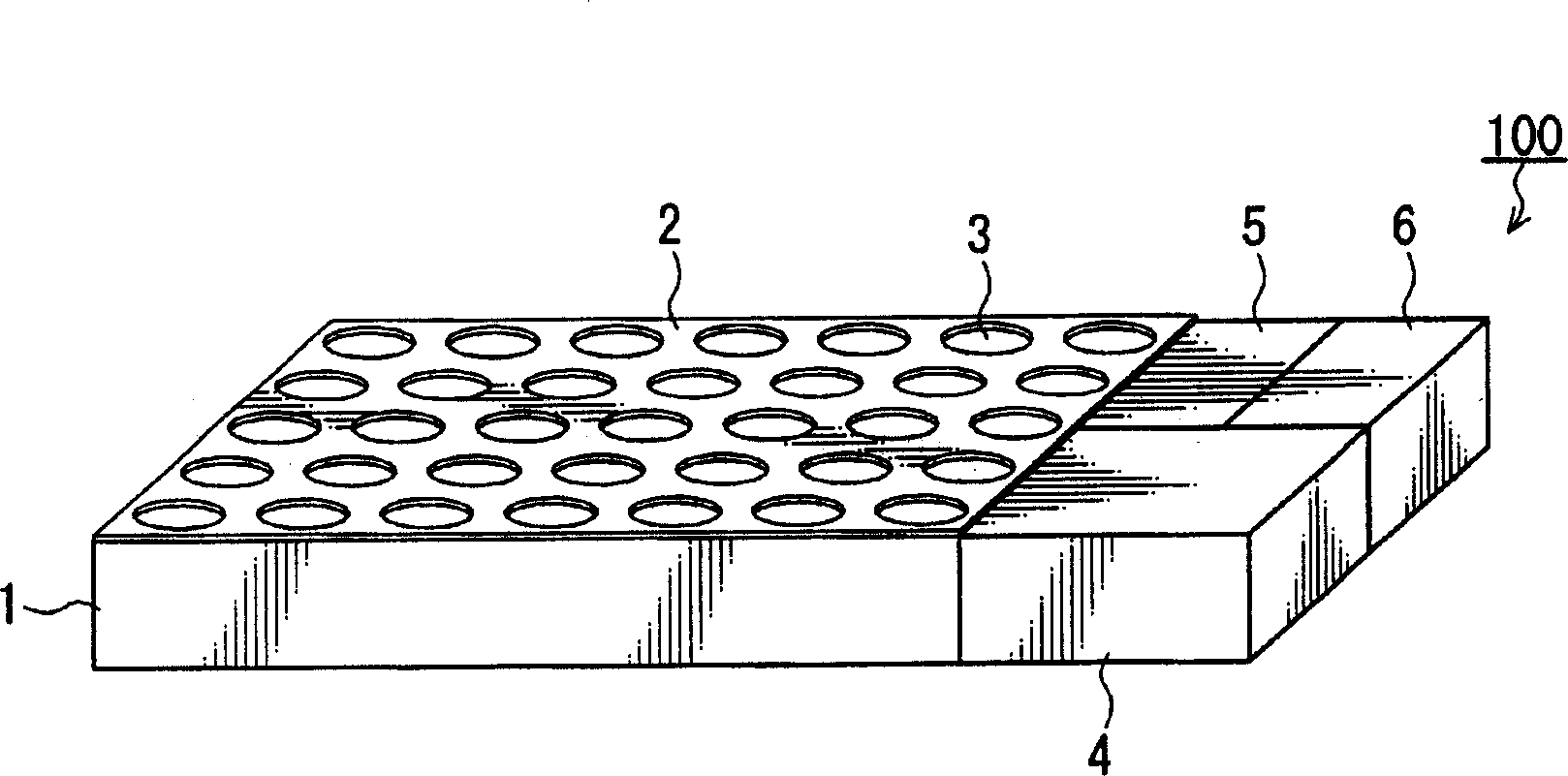

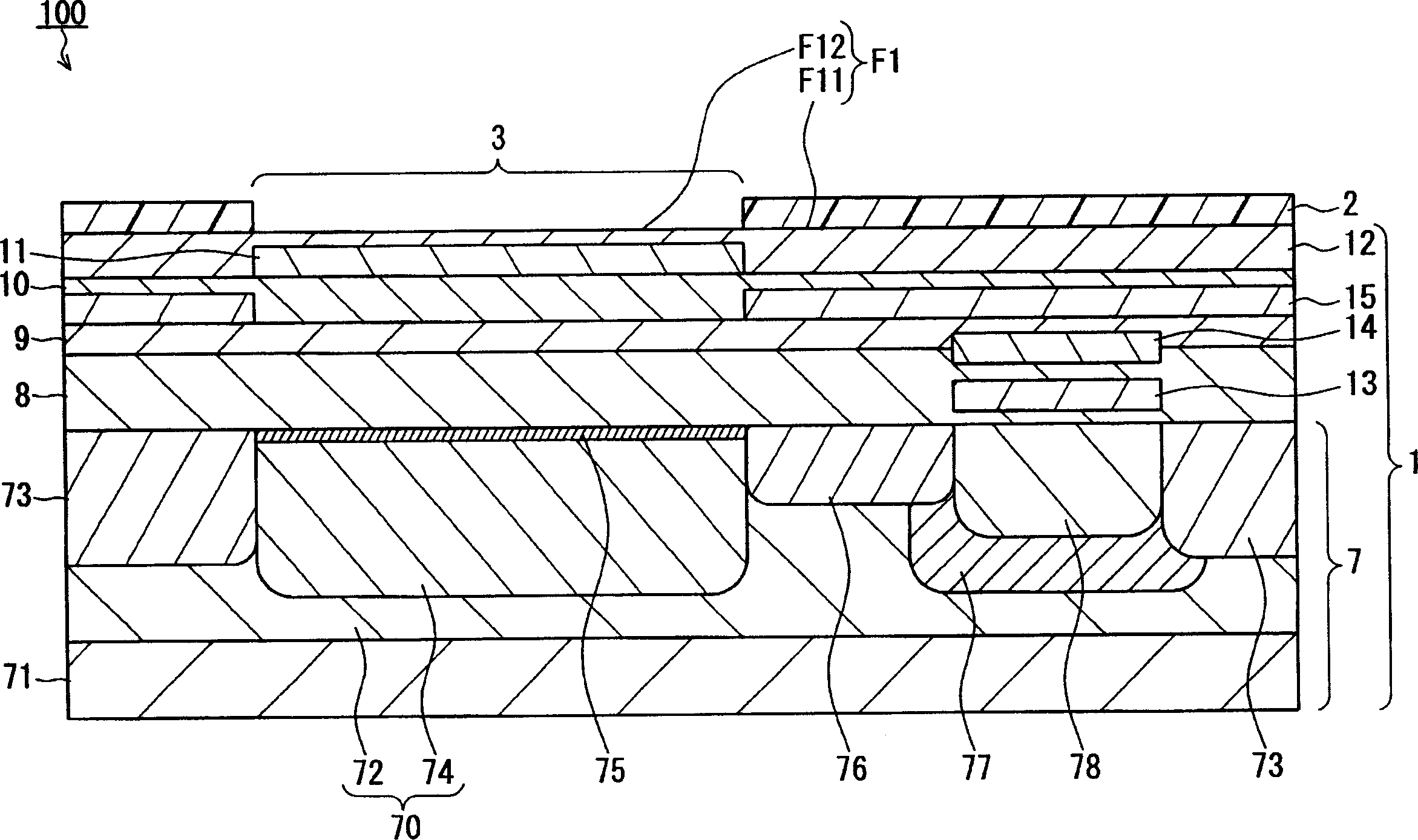

[0110] figure 1 It is a perspective view showing the first embodiment of the sample inspection device of the present invention. figure 2 to express roughly figure 1 A partial cross-sectional view of the basic configuration of the sample inspection device shown. Such as figure 1 and figure 2 As shown, the sample inspection device 100 includes a plate-shaped substrate 1 (semiconductor integrated circuit substrate). The plate-shaped substrate 1 has a sample mounting surface F1. A plurality of recesses 3 of a plurality of liquid droplets of the object to be measured are analyzed. In addition, the sample inspection device 100 further includes a CPU 4 , a storage unit 5 , and a data input / output unit 6 integrally provided on the side surface of the substrate 1 .

[0111] Such as figure 2 As shown, the sample mounting surface F1 is divided into at least a first region F11 covered with a hydrophobic monomolecular film 2 and a plurality of hydrophilic second regions F12 not co...

no. 2 approach

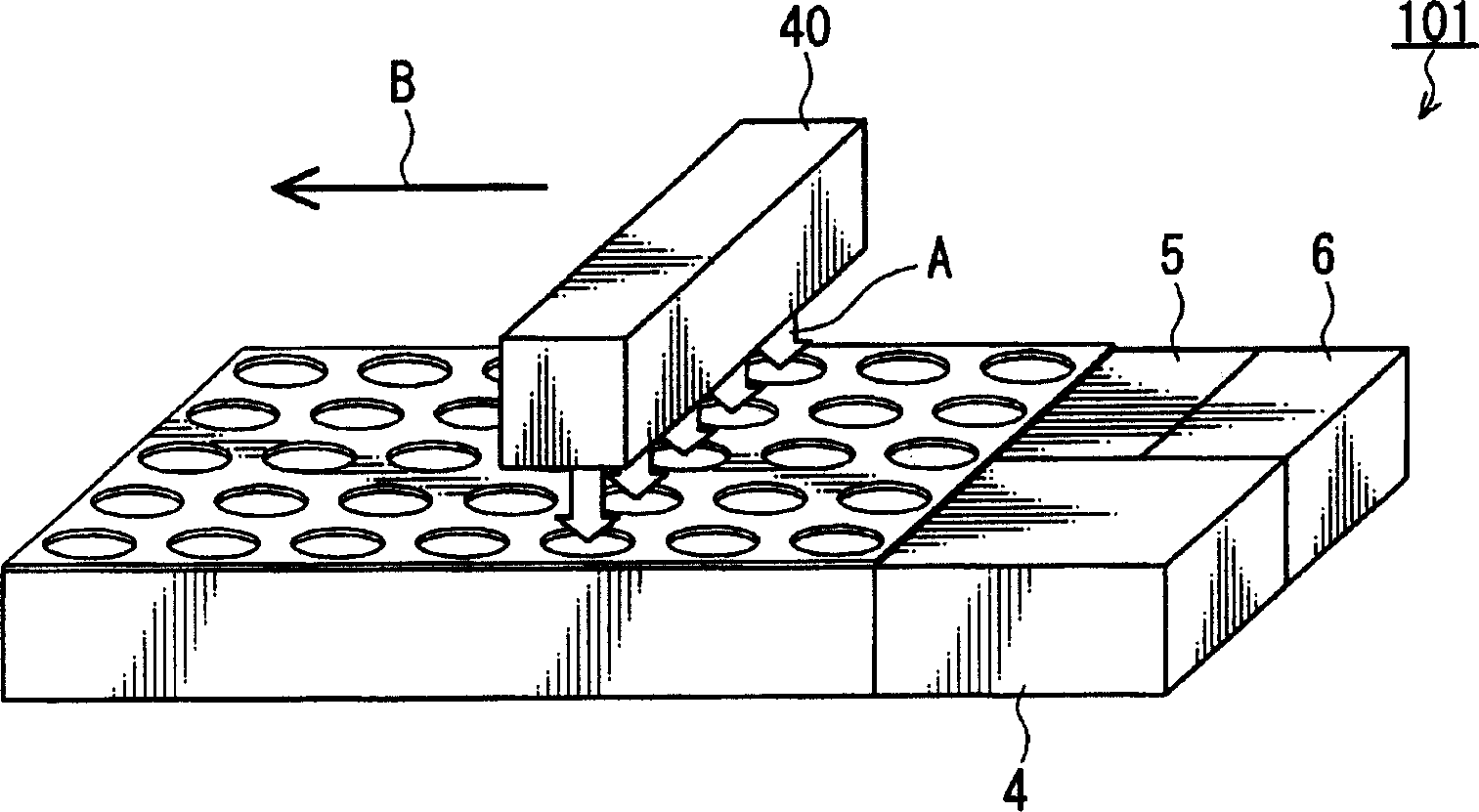

[0274] A second embodiment of the sample inspection device of the present invention will be described below. The sample inspection device 101 of this second embodiment has the following structure, such as figure 1 and figure 2 As shown, in the sample inspection device 100 of the first embodiment, there is also a droplet supply unit 40 (ink jet head) for ejecting a droplet containing an object to be analyzed and measured facing the concave portion 3. of the nozzle. The configuration other than the droplet supply unit 40 is the same as that of the sample inspection device 100 of the first embodiment. The CPU 4 serves as a control unit that adjusts the position of the nozzle relative to the recess 3 by moving the nozzle of the droplet supply unit 40 . That is, the droplet supply unit 40 has a drive mechanism that arbitrarily changes its relative position with respect to the sample mounting surface F1 under the control of the CPU 4 .

[0275] The droplet supply unit 40 will b...

Embodiment 1

[0328] Below, according to use Figure 8 ~ Figure 10 To illustrate the sequence, make a with Figure 7 The sample inspection device 102 shown is a sample inspection device having the same configuration.

[0329] Prepared by semiconductor thin film manufacturing technology with figure 2 Substrate 81 (semiconductor integrated circuit substrate, main surface size: 15 mm × 25 mm, thickness: 0.8 mm) with the same configuration as substrate 1 shown, the number of photodiodes arranged two-dimensionally at equal intervals: 120,000, arranged two-dimensionally at equal intervals Density of photodiodes: 37000 / cm2 ).

[0330] Then, according to the monomolecular film forming step according to the present invention, the monomolecular film 83 was formed on the main surface (the surface serving as the sample mounting surface) of the substrate 81 in the following procedure.

[0331] First, the main surface of the substrate 81 is washed with ultrapure water, and droplets of ultrapure water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com