Production process for picking-up against cancer pharmaceutical product of beta element from Curcuma

A production process, the technology of elemene, is applied in the production process field of extracting β-elemene anti-cancer raw material drug, which can solve the problem of large amount of β-elemene anti-cancer raw material drug and the industrial production level of β-elemene Low cost, too much feeding at one time, etc., to achieve good anti-cancer effect, strong anti-tumor effect, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

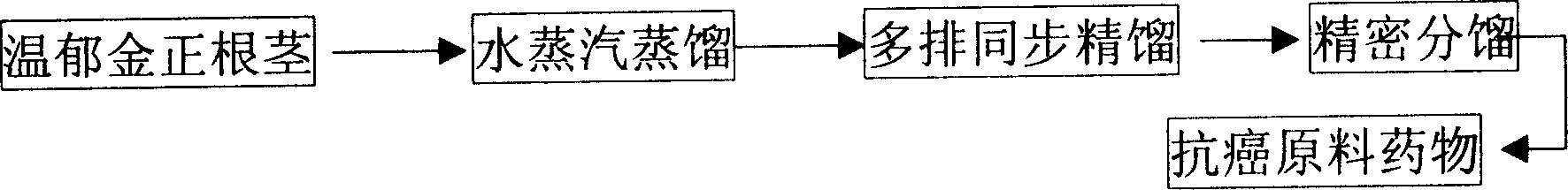

[0017] see figure 1 , a production process for extracting β-elemene anti-cancer raw materials from Curcuma curcuma, using the rhizome of Curcuma curcuma as the raw material for extracting β-elemene, and obtaining anti-cancer drugs through steam distillation, multi-row synchronous rectification, and precision fractionation. Cancer Raw Drugs.

Embodiment 2

[0019] see figure 1 and figure 2 , a production process for extracting β-elemene anti-cancer raw material drug from Curcuma curcuma:

[0020] a. get the positive rhizome of Wen Yujin, and use the steam distillation tower kettle to carry out steam distillation to obtain the zedoary zedoary volatile oil;

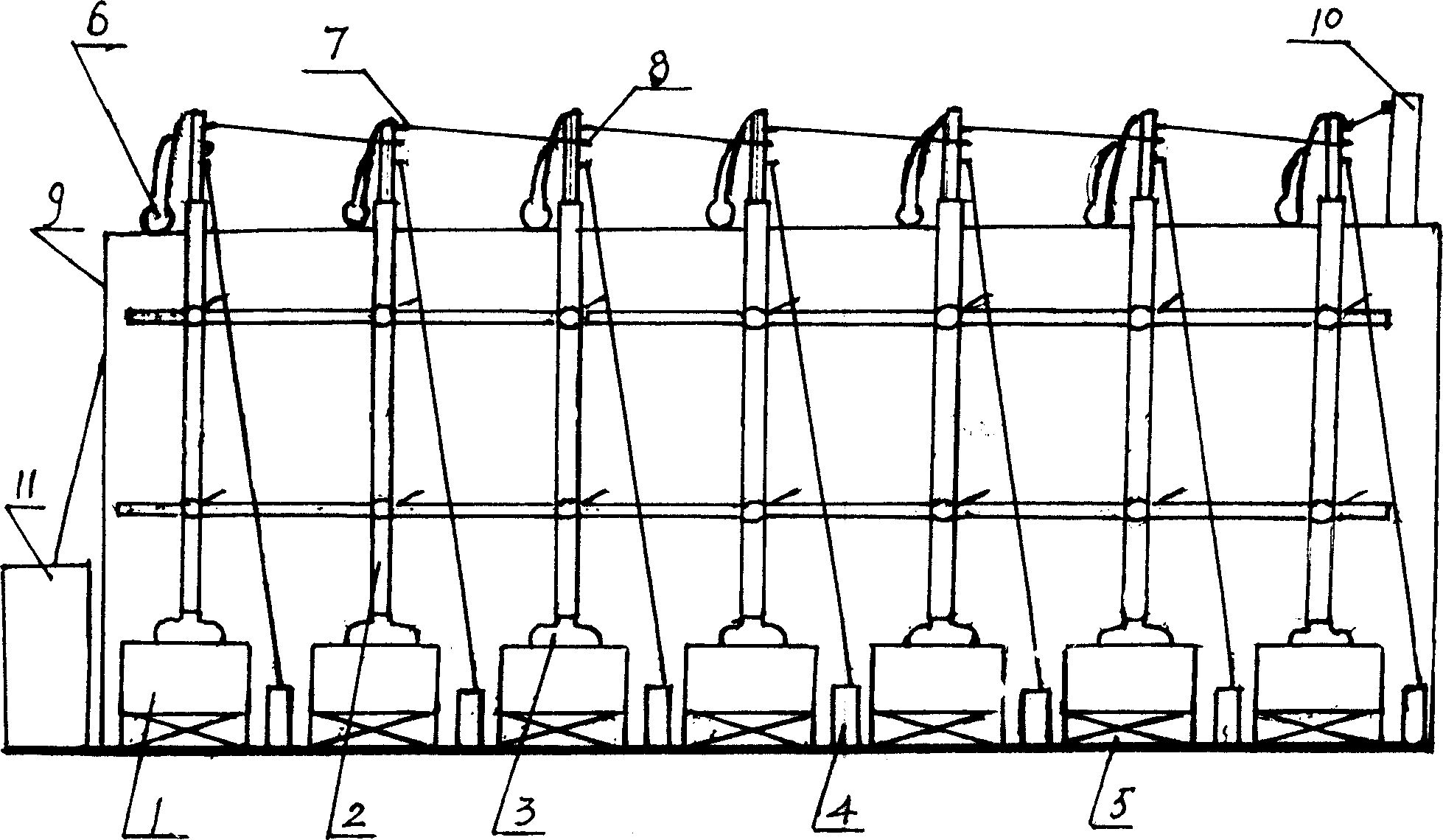

[0021] b. Get the zedoary zedoary volatile oil obtained in a step, adopt G-row type synchronous rectification device to carry out multi-row synchronous rectification, the vacuum degree is 1~3HHmg, and the fraction when collecting column temperature is 78~88 ℃;

[0022] c. Take the fraction collected in step b and add it to a flask under a precision fractionation column for precision fractionation. The precision fractionation column is filled with 2.5mm×2.5mm Q-type stainless steel, and the vacuum degree is 1-3HHmg. It is a fraction at 90-110 DEG C, and an anticancer raw material drug with a content of β-elemene of more than 93% is obtained.

[0023] see figure 2 , the G-...

Embodiment 3

[0028] see figure 1 and figure 2 , a production process for extracting β-elemene anti-cancer raw material drug from Curcuma curcuma:

[0029] A. with embodiment two;

[0030] b. with embodiment two, five cuts when collecting column temperature are 60~90 ℃;

[0031] c. remove the second crystallization cut that b step obtains, get the first cut that b step obtains and the fourth cut merge, get the third cut that b step obtains and the fifth cut merge, Put them into two flasks under the same precision fractionation column respectively. The precision fractionation column is filled with 2.5mm×2.5mm Q-type stainless steel. Then the four fractions from the two precision fractionation columns were combined in order, and the content of β-elemene, δ-elemene and γ-elemene in each fraction was determined after testing. It is compared to an anticancer raw material drug containing 70-85% of β-elemene, 1-16% of the sum of δ-elemene and γ-elemene, and more than 86% of the sum of elemene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com