Preparation method of refining xylan

A technology for xylan and wood purification, applied in oligosaccharides and other directions, can solve the problems of high cost and sewage generation, and achieve the effect of high efficiency and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

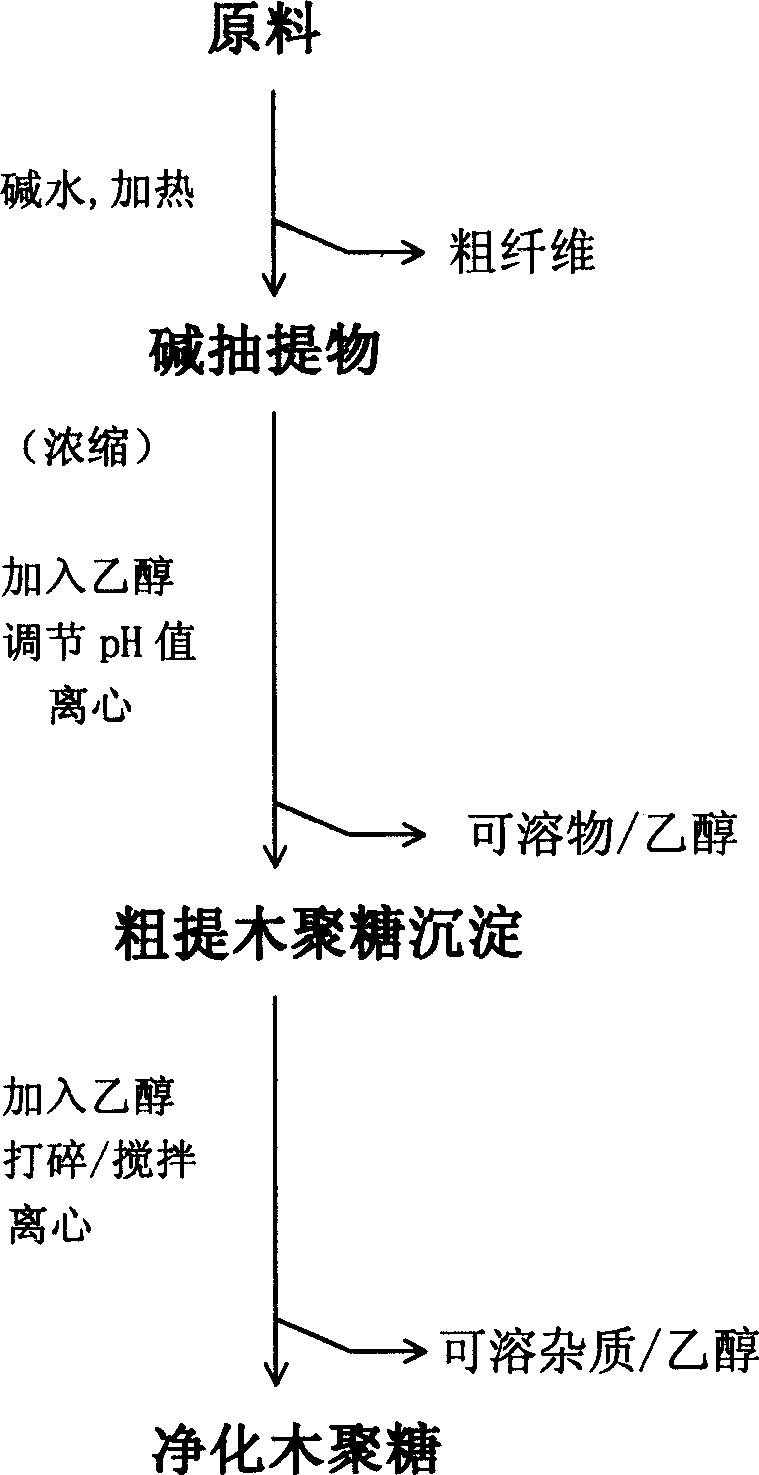

Method used

Image

Examples

Embodiment 1

[0037] (1) Shake the non-mildew straw to remove dust and dry it and grind it into 1-20mm long shredded grass;

[0038] (2) Weigh 10 kg of grass silk, add 50 l of 2.5% KOH solution, soak for 4 hours, cook for 15-30 minutes, squeeze out the solution; minutes, squeeze out the solution. Combine the two parts of the extruded liquid, and centrifuge at a centrifugal force of 8000g for 30min to obtain about 50l of the supernatant;

[0039] (3) Add 150L of 95% ethanol, adjust the pH value to 6.0 with phosphoric acid after mixing, centrifuge at 8000g for 15min, and collect the precipitated crude xylan;

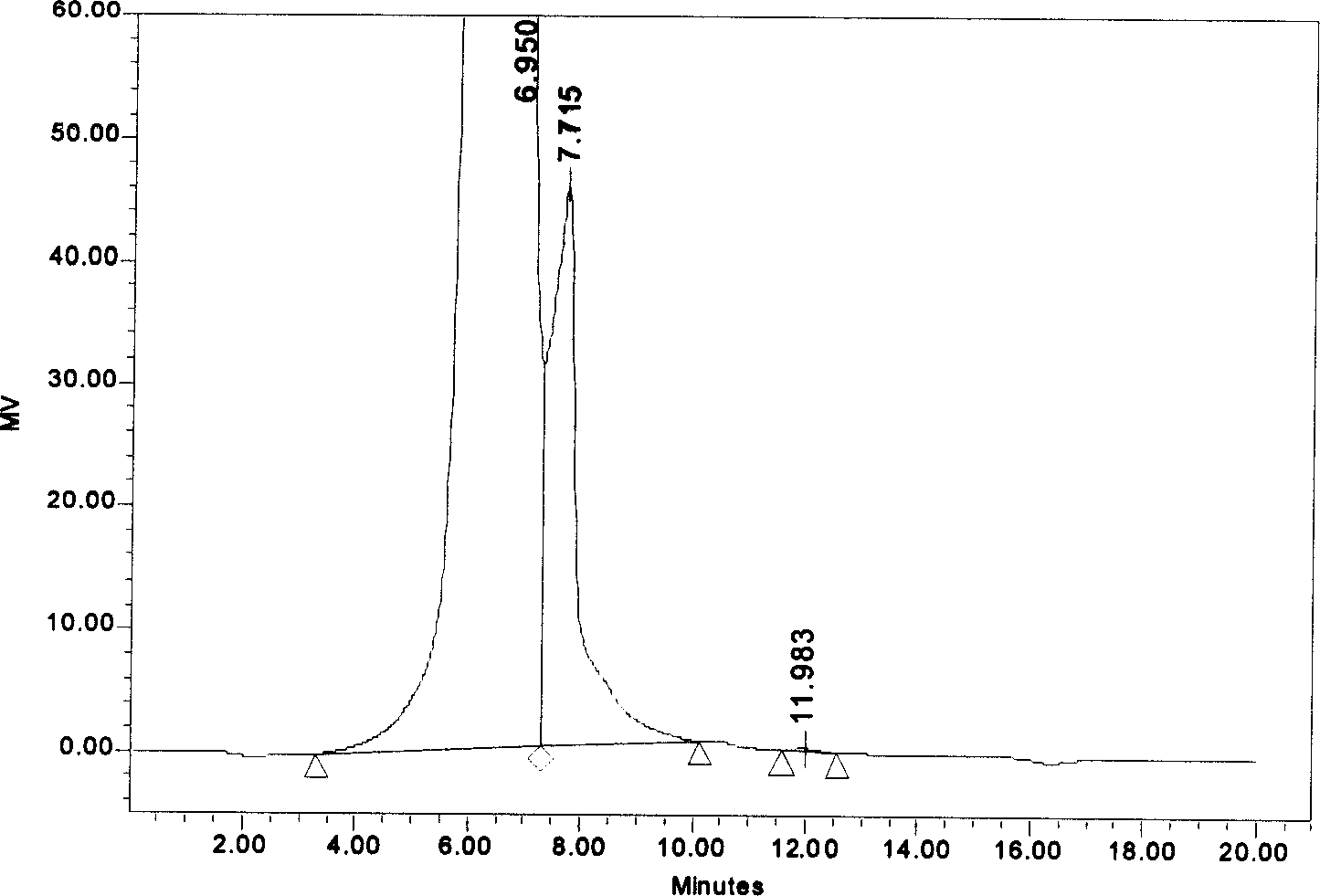

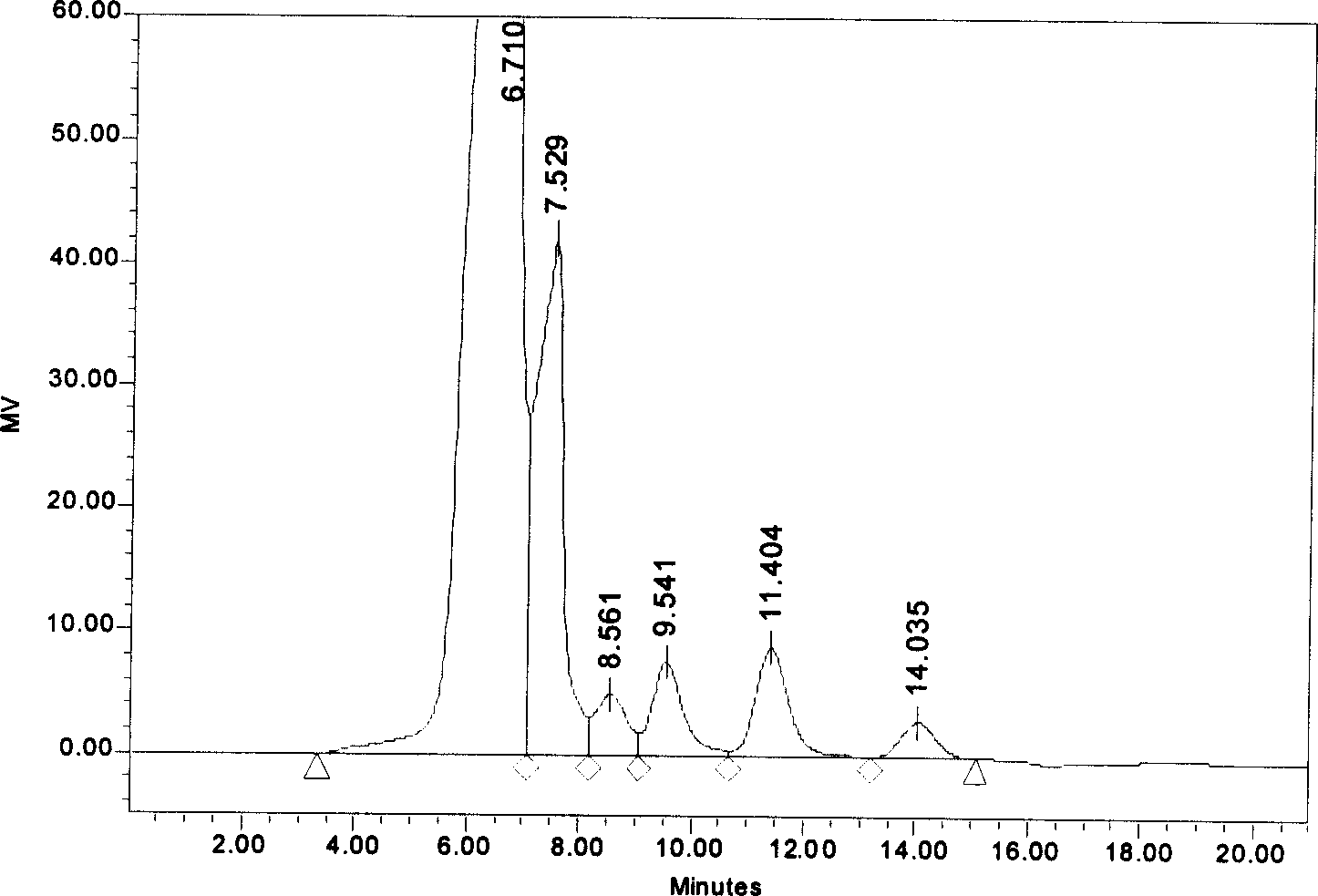

[0040] (4) Add 50 l of 95% ethanol to the coarsely extracted xylan precipitate, break it up and stir at low speed for 2 hours to fully balance it, then centrifuge at 8000 g for 15 min to collect the precipitate; add ethanol and repeat the above process twice to obtain the product , take a product sample and analyze it by HPLC as figure 2 As shown, where HPLC analysis column: Sugarpa...

Embodiment 2

[0041]Embodiment 2: basically the same as Example 1, the difference is that with 10kg broken wheat straw, 30L 1% NaOH solution, 80% ethanol 50L crudely extract xylan;

Embodiment 3

[0042] Embodiment 3: basically the same as Example 1, the difference is that 10kg of bagasse is used as a raw material, 100L of 5% KOH solution is used to extract alkali-soluble substances, and 80L of alkali extract is obtained, which is then concentrated to 40L; then 85% ethanol is added 200L crude xylan extraction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com