Collagen and method for preparing collagen from skins of birds

A collagen and protoprotein technology, which is applied in the field of type I poultry skin collagen, can solve the problems of limited application of collagen and low degree of collagen purification, and achieves the effects of simple and easy procedure, simple method and low preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

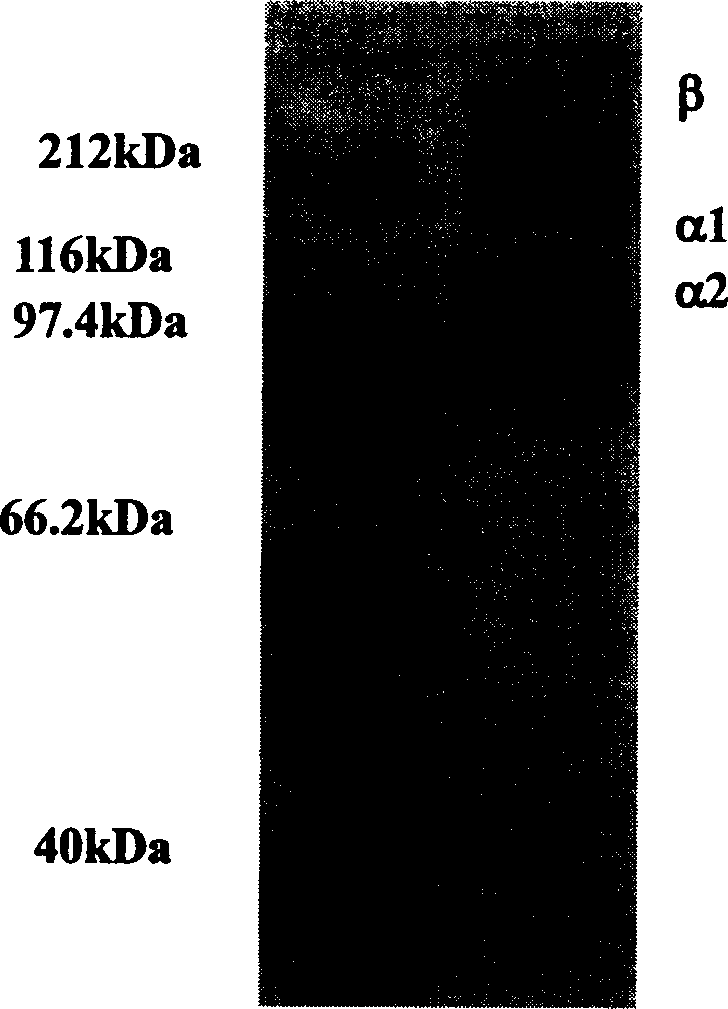

Image

Examples

Embodiment 1

[0023] Embodiment 1: preparation of quail skin collagen

[0024] 1. Wash the quail skin. Soak and rinse the frozen quail skin with 100ml of 4°C tap water, remove the quail hair and subcutaneous tissue until there is no fluff in the soaking solution except the whole piece of quail skin, then soak and rinse with deionized water for 5 times.

[0025] 2. Alkali treatment of quail skin. Use 100ml of 0.1M NaOH solution to soak the quail skin after (1) treatment at 4°C for 2-3 days, and replace the 0.1M NaOH solution once a day. Then fully wash the quail skin after alkali treatment with deionized water until about pH7.

[0026] 3. Acid soluble collagen. Dissolve the treated quail skin in 40ml of 0.5M acetic acid-sodium acetate (1:1 / V:V) buffer solution, extract continuously for 3 days at 4°C, and filter with gauze. The residue was acid-dissolved and extracted again, and the steps were the same as above, and the two filtrates were combined.

[0027] 4. Purify co...

Embodiment 2

[0029] Embodiment 2: preparation of quail skin collagen

[0030] 1. Wash the quail skin. Soak and rinse the frozen quail skin with 100ml of tap water at 1-10℃, remove the quail hair and subcutaneous tissue until there is no fluff in the soaking liquid except the whole piece of quail skin, then soak and rinse with deionized water for 5 times .

[0031] 2. Alkali treatment of quail skin. with 3% Ca(OH) 2 Soak (1) treated quail skin in 100ml of solution at 1-10°C for 3-4 days, replace with 3% Ca(OH) once in the morning and evening 2 solution. Then fully wash the quail skin after alkali treatment with deionized water until about pH7.

[0032] 3. Acid soluble collagen. Dissolve the treated quail skin in 40ml of 0.5M acetic acid-sodium acetate (1:1 / V:V) buffer solution, extract continuously for 3 days at 4°C, and filter with gauze. The residue was acid-dissolved and extracted again, and the steps were the same as above, and the two filtrates were combined.

[003...

Embodiment 3

[0034] Embodiment 3: preparation of salted chicken skin collagen

[0035] 1. Wash the chicken skin. Soak and rinse the frozen chicken skin with 200ml of 5°C tap water, remove chicken feathers and subcutaneous tissue until there is no fluff in the soaking solution except the whole piece of chicken skin, then soak and rinse with deionized water for 5 times.

[0036] 2. Alkali treatment of chicken skin. The chicken skin was salted with NaCl (1:1 w / w) for 7 days, and then the alkali-treated chicken skin was fully washed with deionized water until the pH was about 7.

[0037] 3. Acid soluble collagen. Dissolve the chicken skin treated in (2) in 100ml of 0.5M acetic acid-sodium acetate (1:1 / V:V) buffer solution, extract at 4°C for 3-4 days, and filter with gauze. The residue was acid-dissolved and extracted again, and the steps were the same as above, and the two filtrates were combined.

[0038] 4. Purify collagen. The above filtrate was centrifuged at 10,000 r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com