Strong malleableizing technique for tire mold and equipment

A technology for tire molds and processing equipment, applied in heat treatment equipment, heat treatment furnaces, manufacturing tools, etc., can solve the problems of restricting the working performance and service life of tire molds, poor comprehensive mechanical properties of tire molds, and reducing equipment utilization, so as to save Effects of fuel consumption, reduction of tissue stress and thermal stress, and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, tire mold strengthening and toughening treatment equipment.

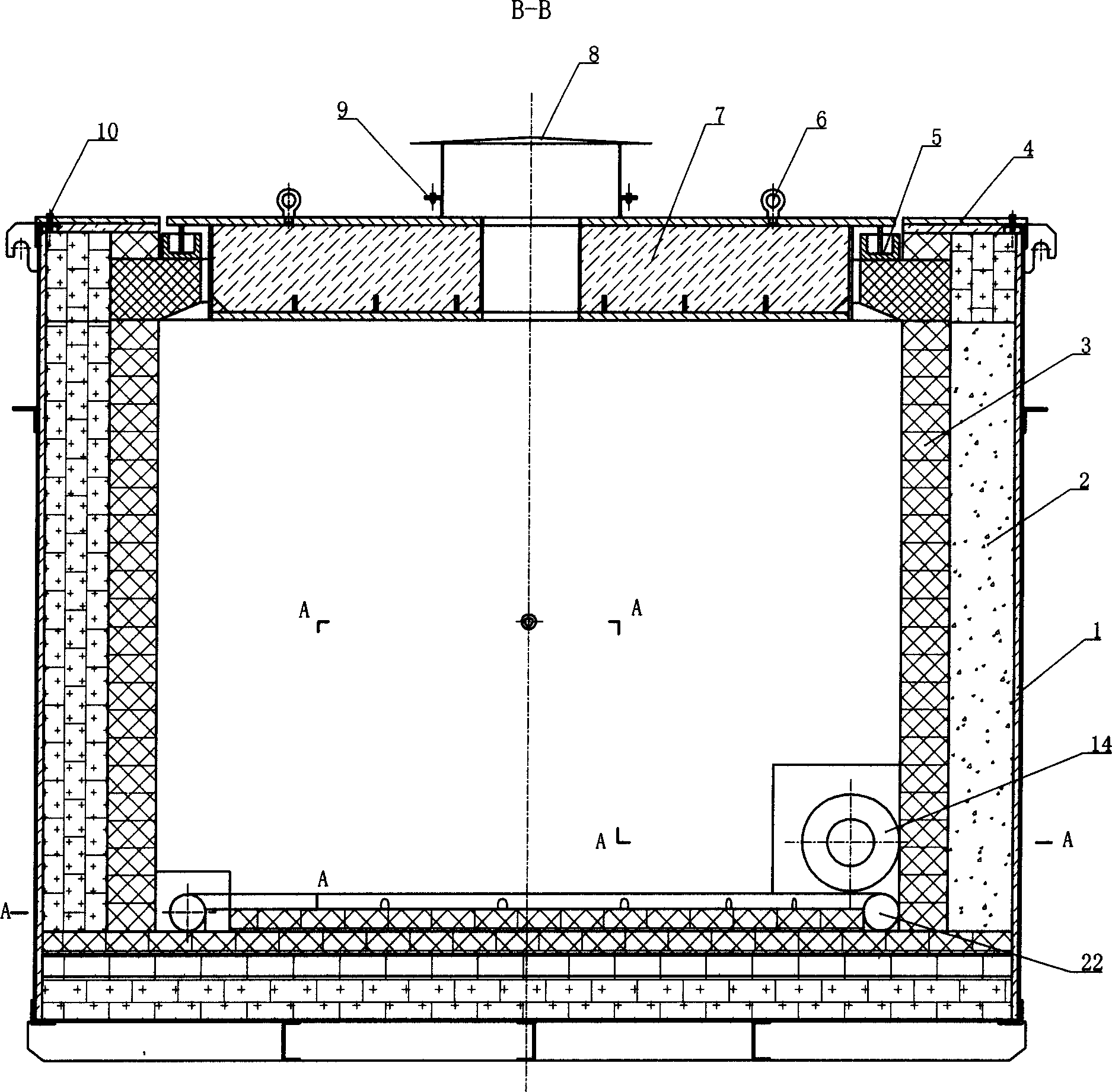

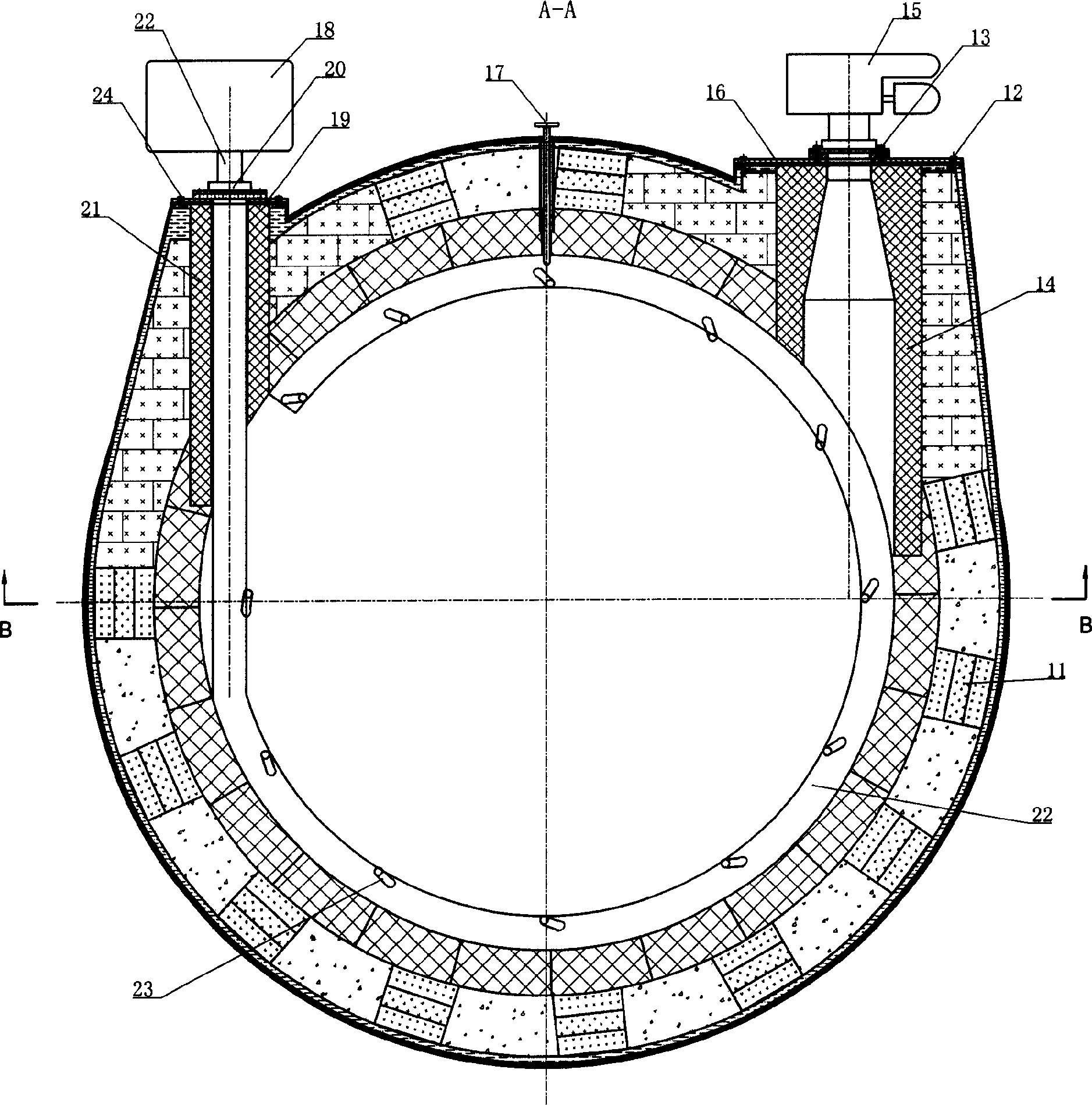

[0026] refer to figure 1 , figure 2 , the tire mold toughening treatment equipment is composed of a furnace body, a heating device, a cooling device and a temperature control device. The furnace body mainly includes a furnace shell 1, a furnace lining 2, a refractory brick layer 3, a cover plate 4, a sand seal ring 5 and a The cover 7 and the heating device are composed of a fuel burner 15 and a guide brick tube 14 that guides the combustion hot gas into the furnace. The inner end of the brick tube communicates with the furnace; the cooling device is composed of a blower 18, an air guide pipe 22 and an air outlet pipe 23, and the air guide pipe starts from the air outlet of the blower and extends to the bottom periphery of the furnace. 12 cooling gas outlet pipes 23 are installed equidistantly, and the outlet pipes are welded on the air guide pipe 22 in sequence at three angles of 60°, 45°, a...

Embodiment 2

[0028] Embodiment 2, tire mold strengthening and toughening treatment process.

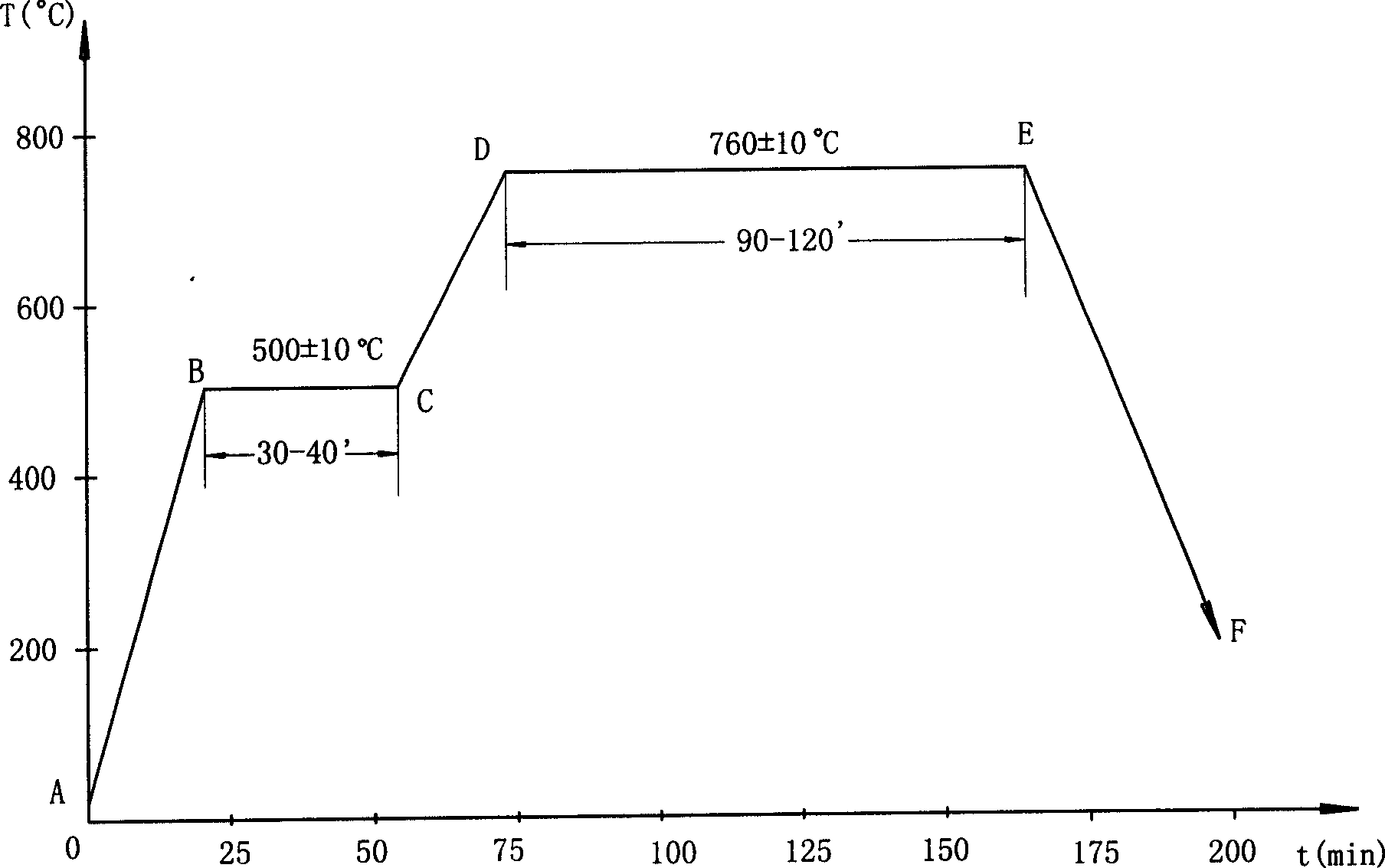

[0029] The tire mold toughening treatment process is carried out in the equipment described in embodiment 1, and its process includes:

[0030] A, the tire mold blank is packed into the equipment described in embodiment 1, the furnace cover is covered, the fuel burner is opened, and the high temperature hot gas produced by the fuel burner heats the tire mold blank;

[0031] B. When the temperature in the furnace rises to 500°C, control the fuel burner through the temperature control device to keep the temperature in the furnace at 500±10°C, and carry out heat preservation treatment for 30-40 minutes;

[0032] C, continue to heat up;

[0033] D. When the temperature in the furnace rises to 760°C, the temperature in the furnace is also kept at 760±10°C through the temperature control device, and the heat preservation treatment is carried out for 90-120 minutes;

[0034] E. Open the furnace cover, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com