Process for producing aromatic carboxylic acid

A kind of technology of aromatic carboxylic acid and aromatic compound, which is applied in the field of preparing aromatic carboxylic acid and can solve problems such as yield reduction and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

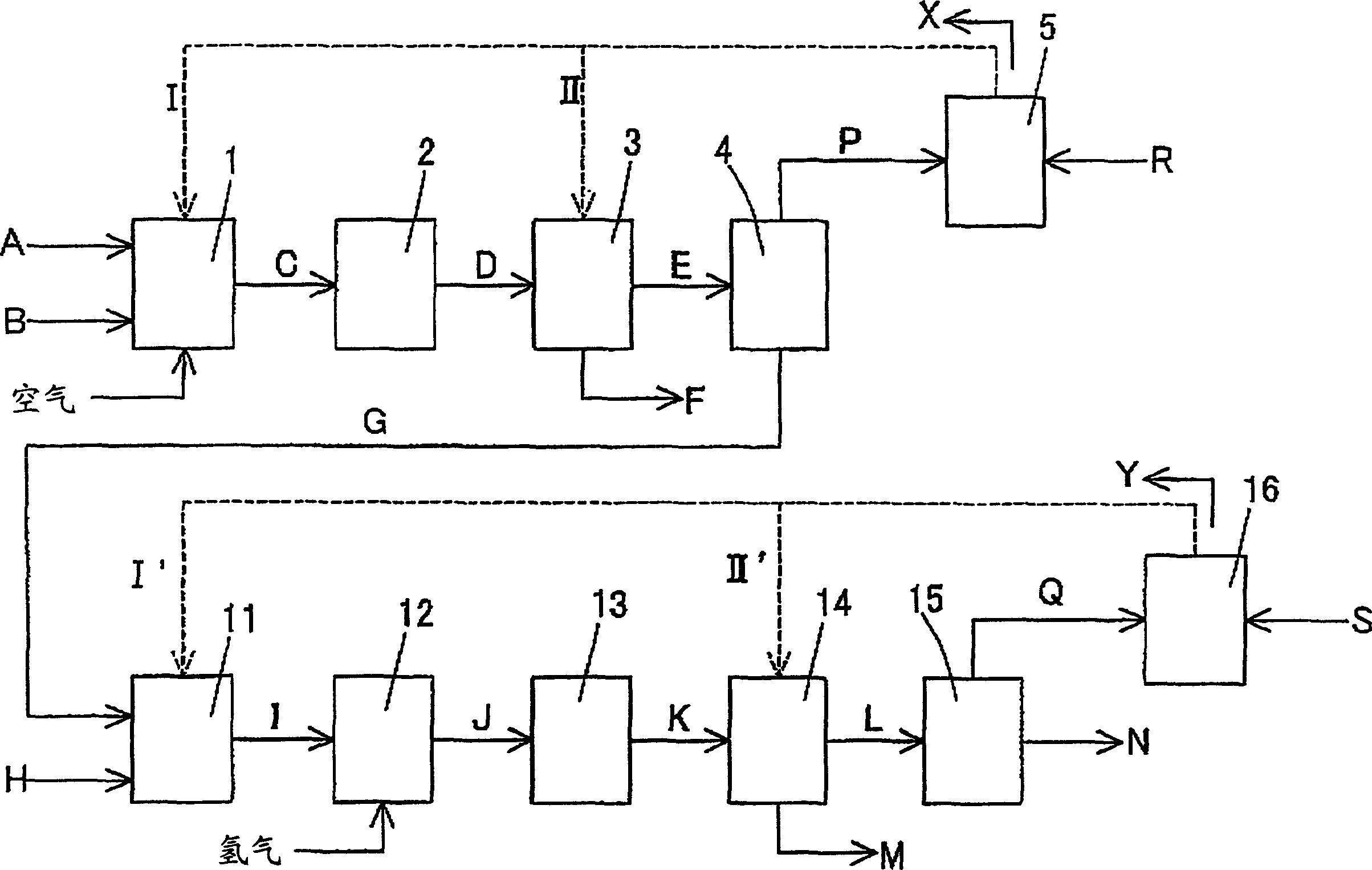

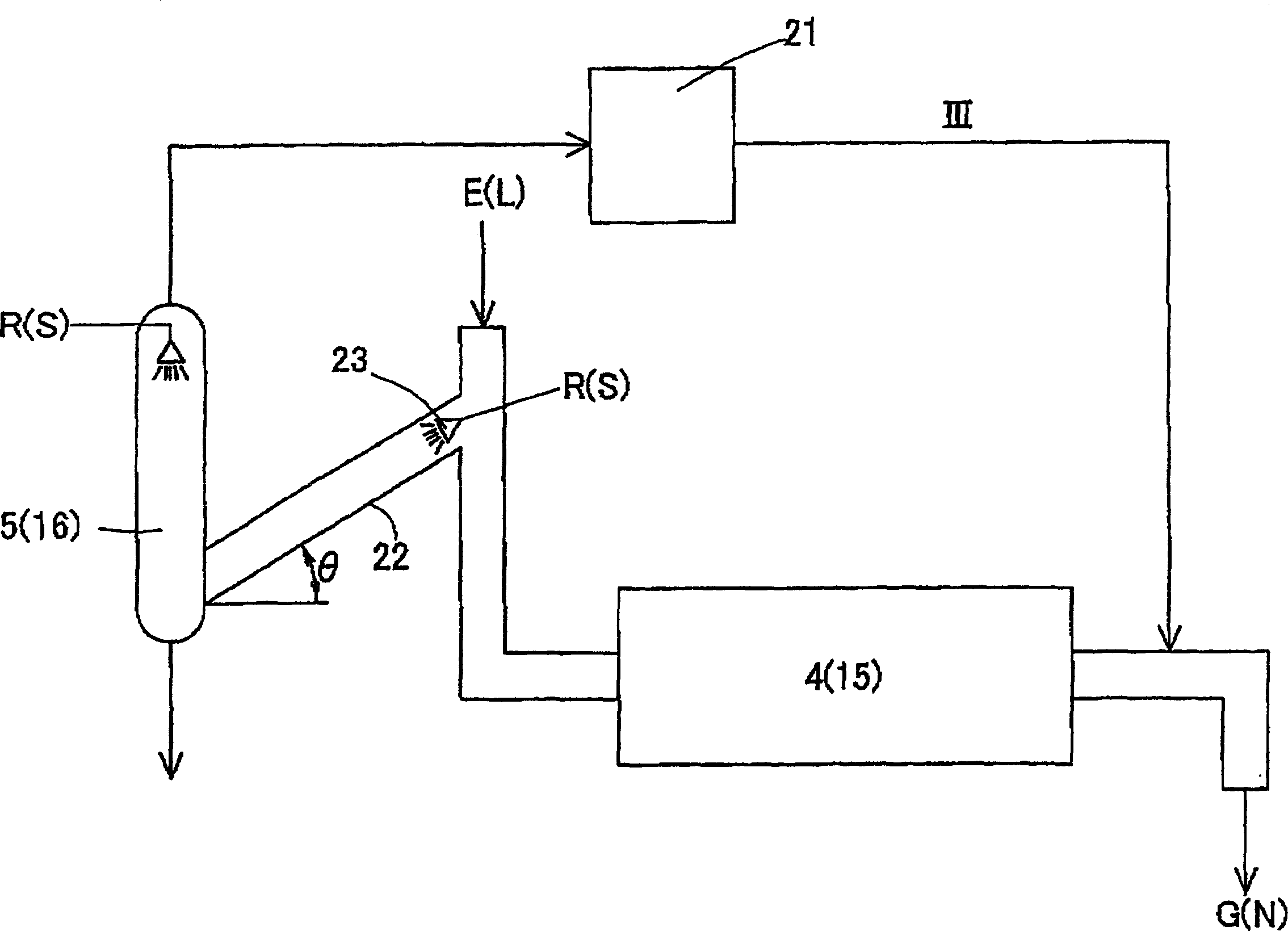

[0014] Incidentally, regarding the reference numerals and signs in the drawings, 1 denotes an oxidation reactor; 2 and 13, a crystallization tank; 3 and 14, a solid-liquid separator; 4 and 15, a dryer; 5 and 16, a recovery device; 11 represents the mixing tank; 21 represents the solvent component removal device; 22 represents the pipeline; 23 represents the spray device; A represents the alkyl aromatic compound; B represents the solvent; C, D and K represent the aromatic carboxylic acid slurry; E and L represent the aromatic carboxylic acid Filter cake; F and M stand for separated mother liquor; G stands for aromatic carboxylic acid crystal; H stands for water medium; I stands for solution; J stands for reduction treatment liquid; N stands for high-purity aromatic carboxylic acid crystal; Denotes liquid; X and Y denote recovered slurry.

[0015] The present invention will be described in detail below.

[0016] Generally, the aromatic carboxylic acid preparation method of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap