Halogen-free resin composite and use thereof

A resin composition and resin technology, applied in the field of halogen-free resin composition, prepreg, laminate, copper clad laminate, and resin glue, can solve the problem of difficult curing agent dosage, low rigidity, and poor heat resistance of the substrate And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

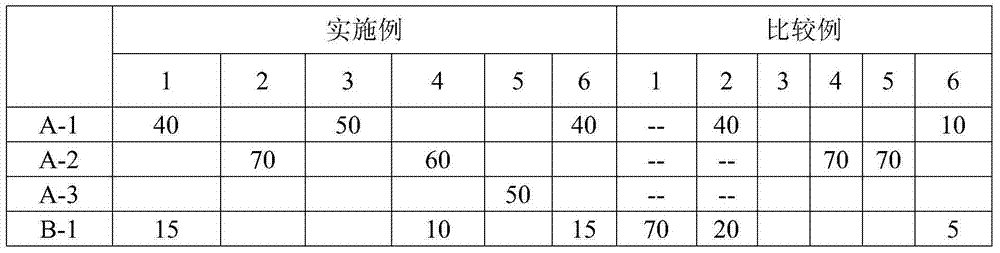

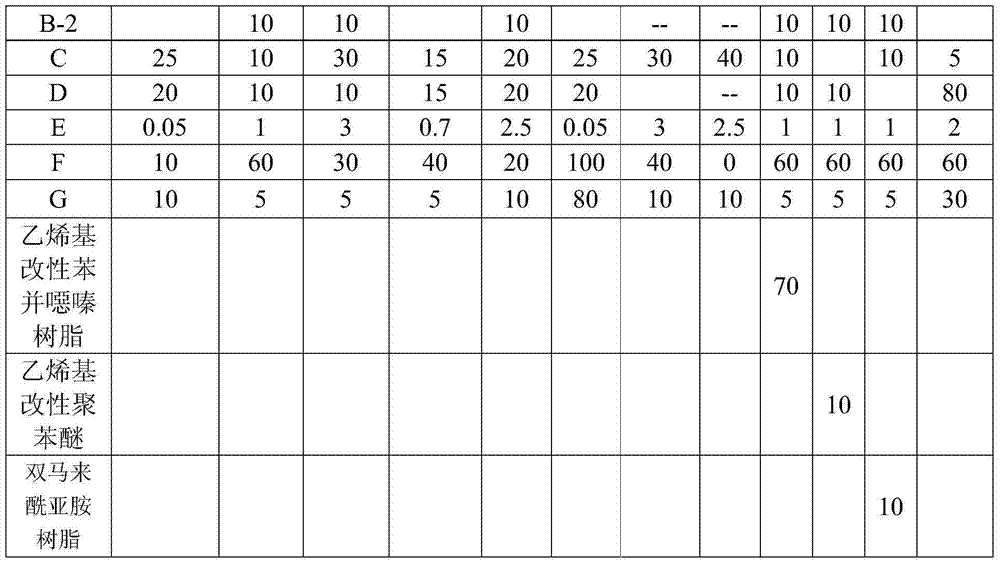

Method used

Image

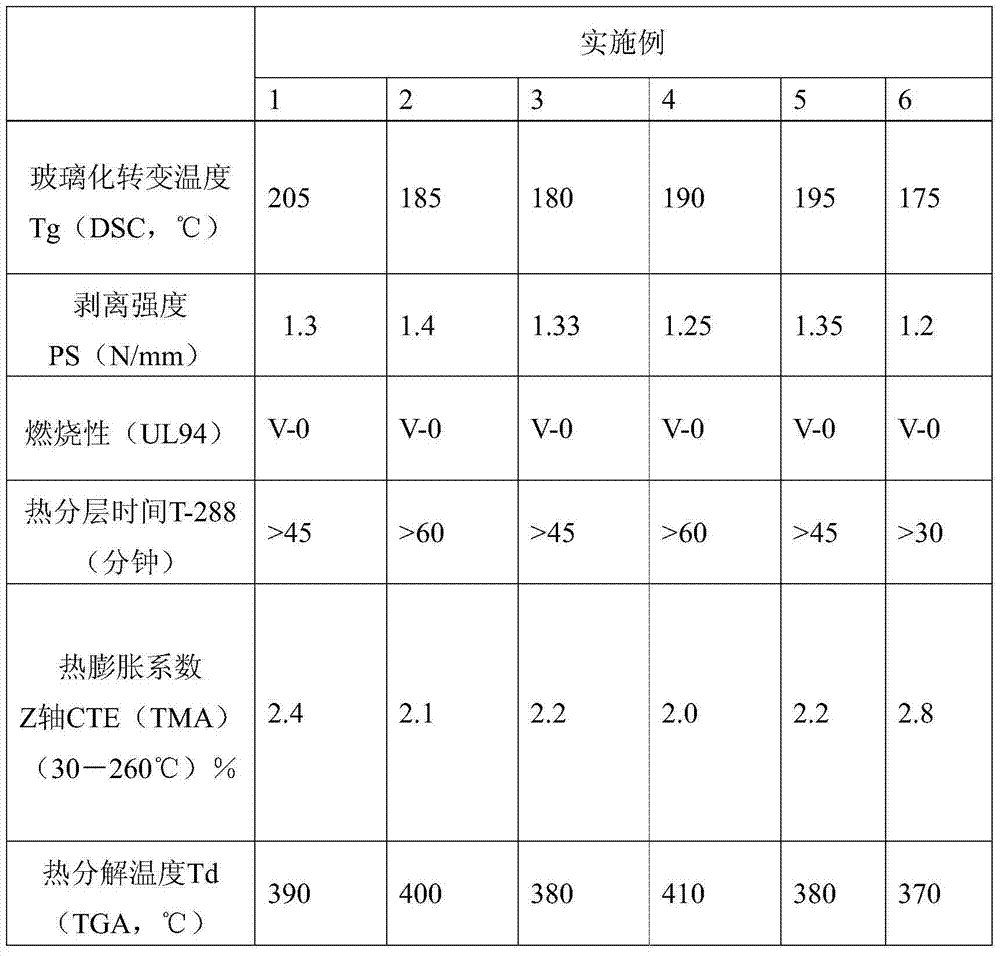

Examples

Embodiment 2

[0084] Compared with Comparative Example 3, the difference between Example 2 and Comparative Example 3 is mainly that the vinyl-modified benzoxazine resin used in the comparative example replaces the allyl-modified benzoxazine resin in the embodiment, because the double bond of the allyl group There is a methylene group in the middle of the adjacent benzene ring, which greatly weakens the conjugation effect of the two, making its double bond easier to undergo free radical polymerization to form a polymer. However, the double bond on the vinyl group in the vinyl-modified benzoxazine resin has a strong conjugation effect with the adjacent benzene ring, which greatly increases the difficulty of free radical polymerization of the double bond on the vinyl group. Therefore, in comparative example 3, the vinyl double bonds in a considerable part of the vinyl-modified benzoxazine resin cannot be polymerized according to free radicals, and the oxazine rings in this part of the vinyl-mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com