Seal fresh water axial plunger hydraulic pump

A hydraulic pump and plunger technology, applied in the field of positive displacement pumps, can solve the problems of unfavorable production, popularization and application, difficult material selection and processing, large radial pressure, etc., and achieves good anti-pollution performance, light weight, and reduced requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The implementation state of the present invention is further described below in conjunction with accompanying drawing:

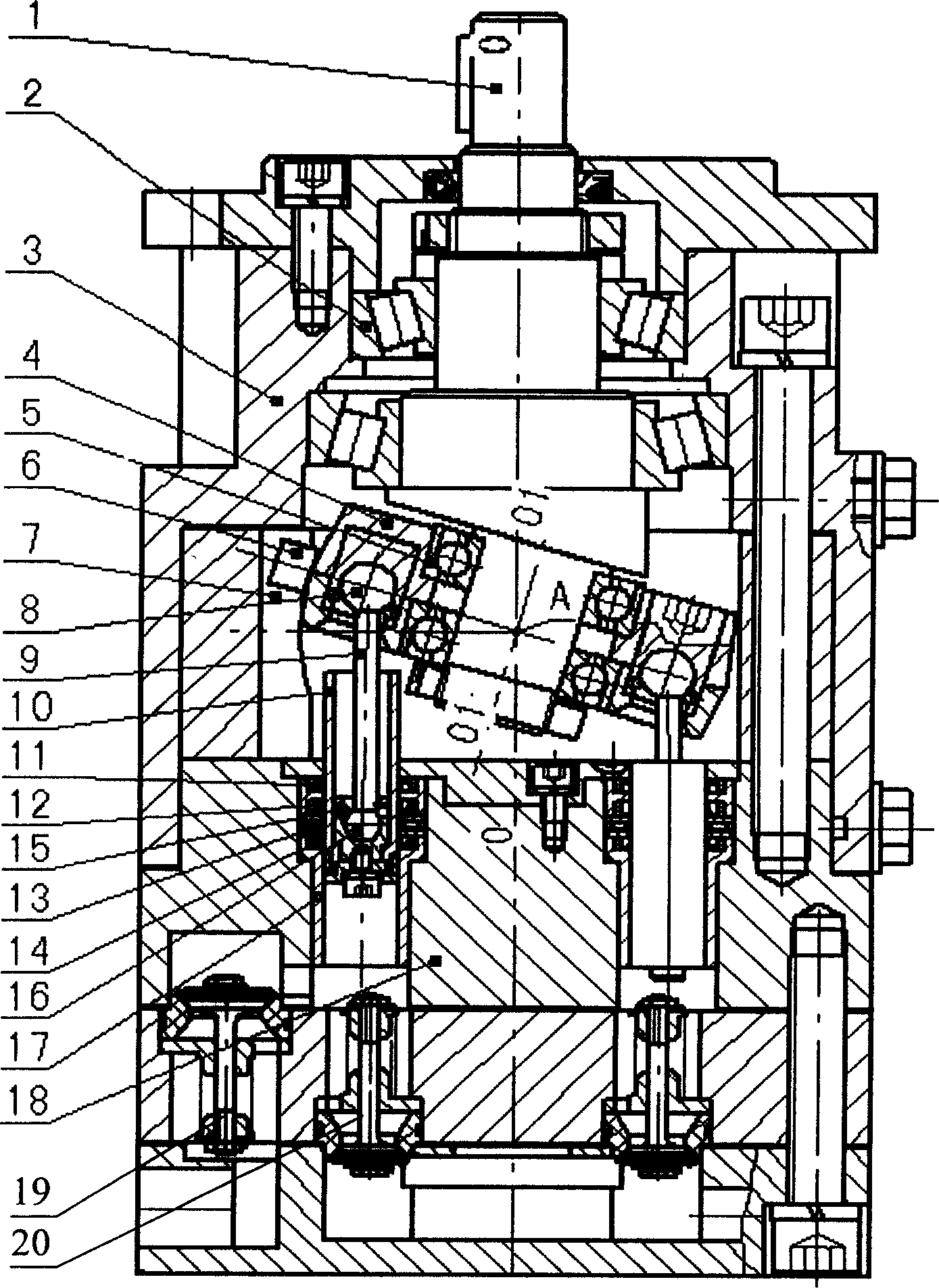

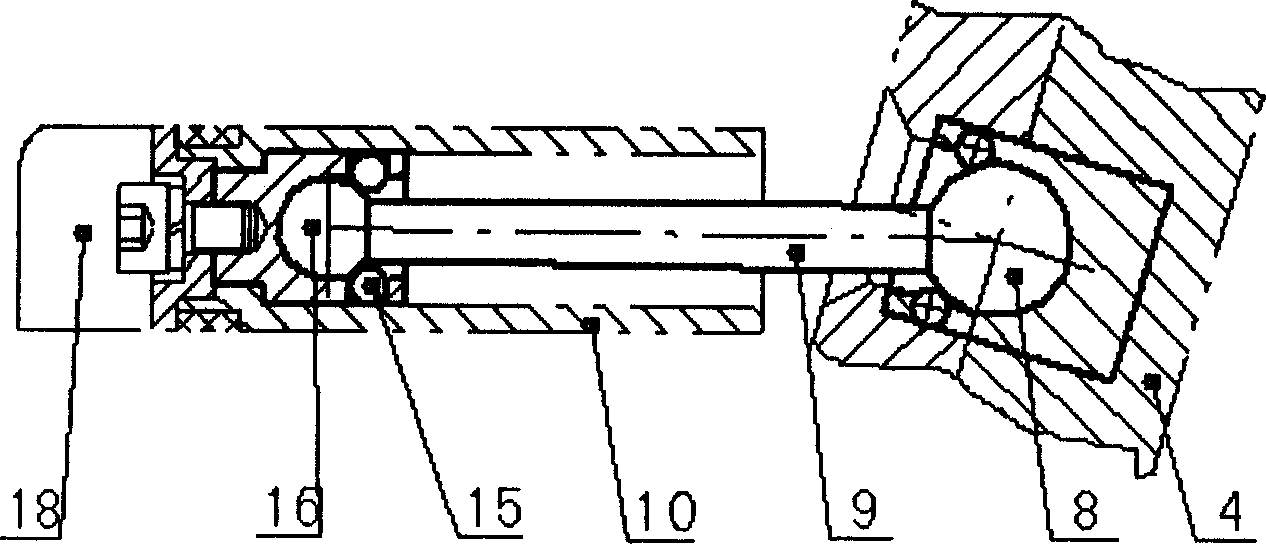

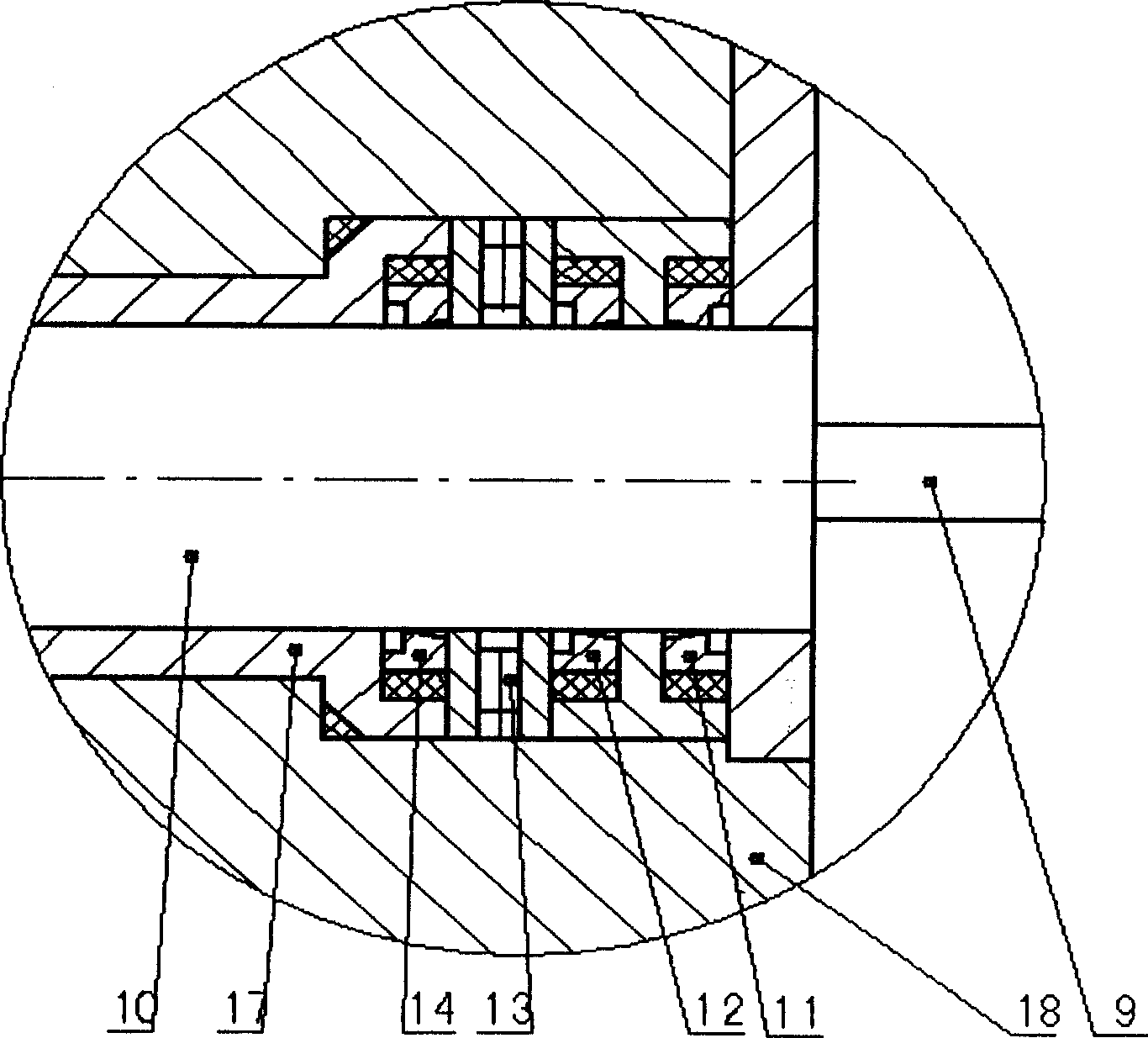

[0021] figure 1 Shown is an embodiment of the present invention, using an axial plunger type crankshaft swash plate connecting rod structure. The input shaft 1 is installed on the pump housing 3 through the support bearing 2, and the lower end of the input shaft forms an acute angle of 18° with the input shaft axis; The guide positioning slider 6 is installed on the disk, and the guide positioning slider slides back and forth in the axial direction in the guide chute 7 fixed on the pump casing; the universal ball joint 8 of a group of connecting rods 9 is installed on the branch of the swash plate On the degree circle, another group of universal ball joints 16 of the connecting rod is connected with a group of plungers 10; The plunger hole on the degree circle or the plunger sleeve 17 reciprocates axially to complete the functions of water absorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com