Reverse cleaning system including off line module of reverse osmosis membrane

A reverse osmosis membrane module and backwashing technology, applied in the field of off-line backwash cleaning system, can solve the problems that the reverse osmosis membrane cannot be applied, cannot be peeled off from the membrane surface, and the cleaning effect is not good, so as to simplify the pretreatment process and reduce the water quality Requirements, the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in detail below in conjunction with embodiment.

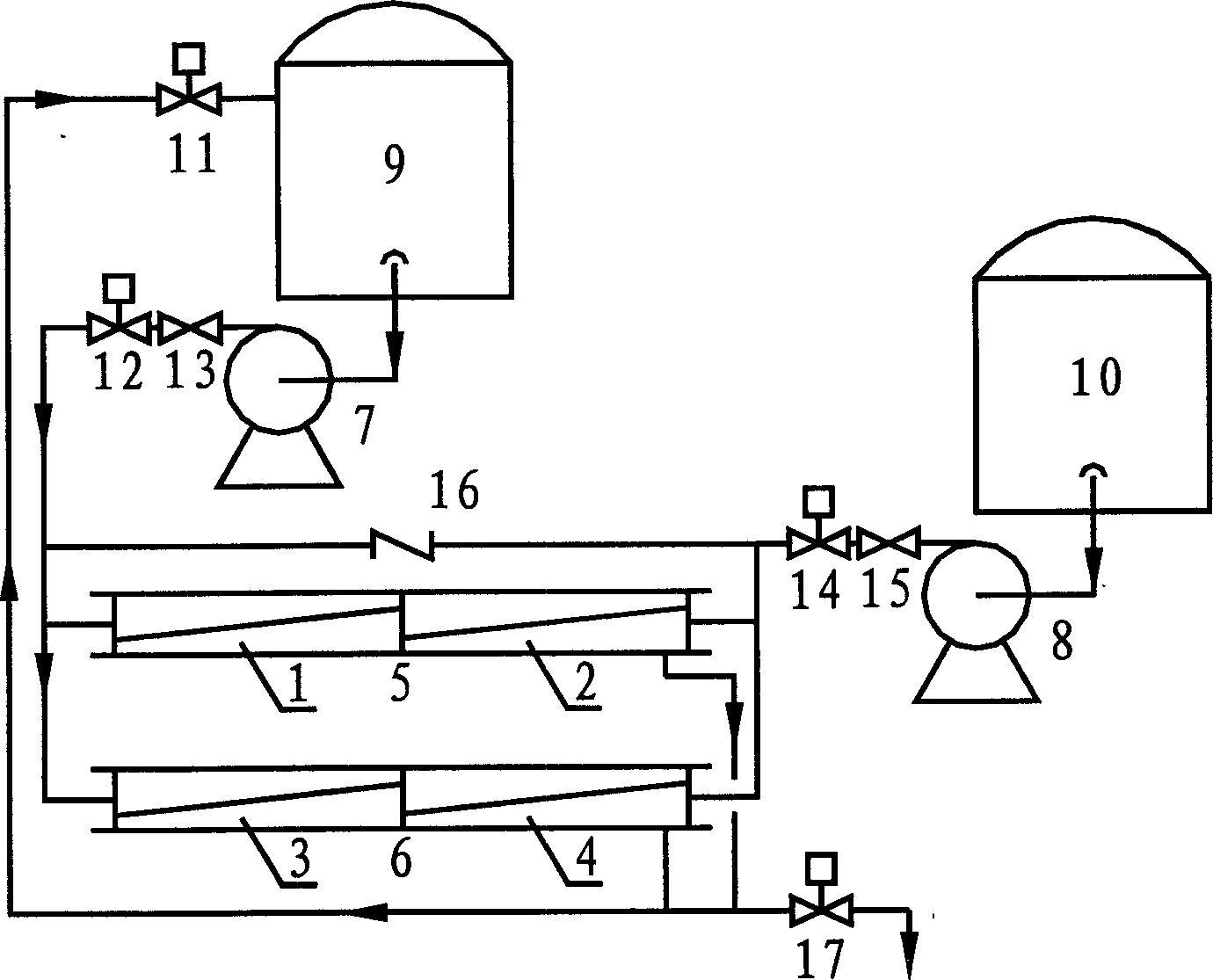

[0043] The invention provides an off-line backwashing system for a reverse osmosis membrane module. The system consists of a positive washing system, a backwashing system, a membrane container and connecting pipelines and valves. This system is used for off-line cleaning of reverse osmosis membrane components. In order to improve the effect of off-line cleaning, this system uses the principle of osmosis. Under the premise of ensuring that the reverse osmosis does not bear back pressure, the fresh water passes through the reverse osmosis membrane under the action of osmotic pressure and enters the concentrated water side cleaning solution with added salt. , so that the reverse osmosis membrane is backwashed, which can effectively improve the cleaning effect. The principle of backwashing is as follows:

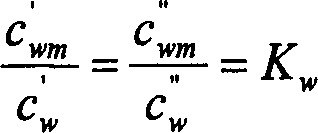

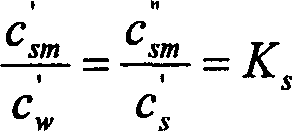

[0044] According to the dissolution-diffusion separation mechanism of reverse osmo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com