Mixed flow water turbine with an eddy suppressor

A water turbine and mixed-flow technology, applied in the field of fluid machinery and engineering equipment, can solve the problems of unit vibration, large shaft periodic swing, output swing, and water flow pressure pulsation and loss in pipelines, and achieve simple structure, low processing cost, The effect of increasing the central flow velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The principle and structure of the present invention will be further described below in conjunction with the accompanying drawings.

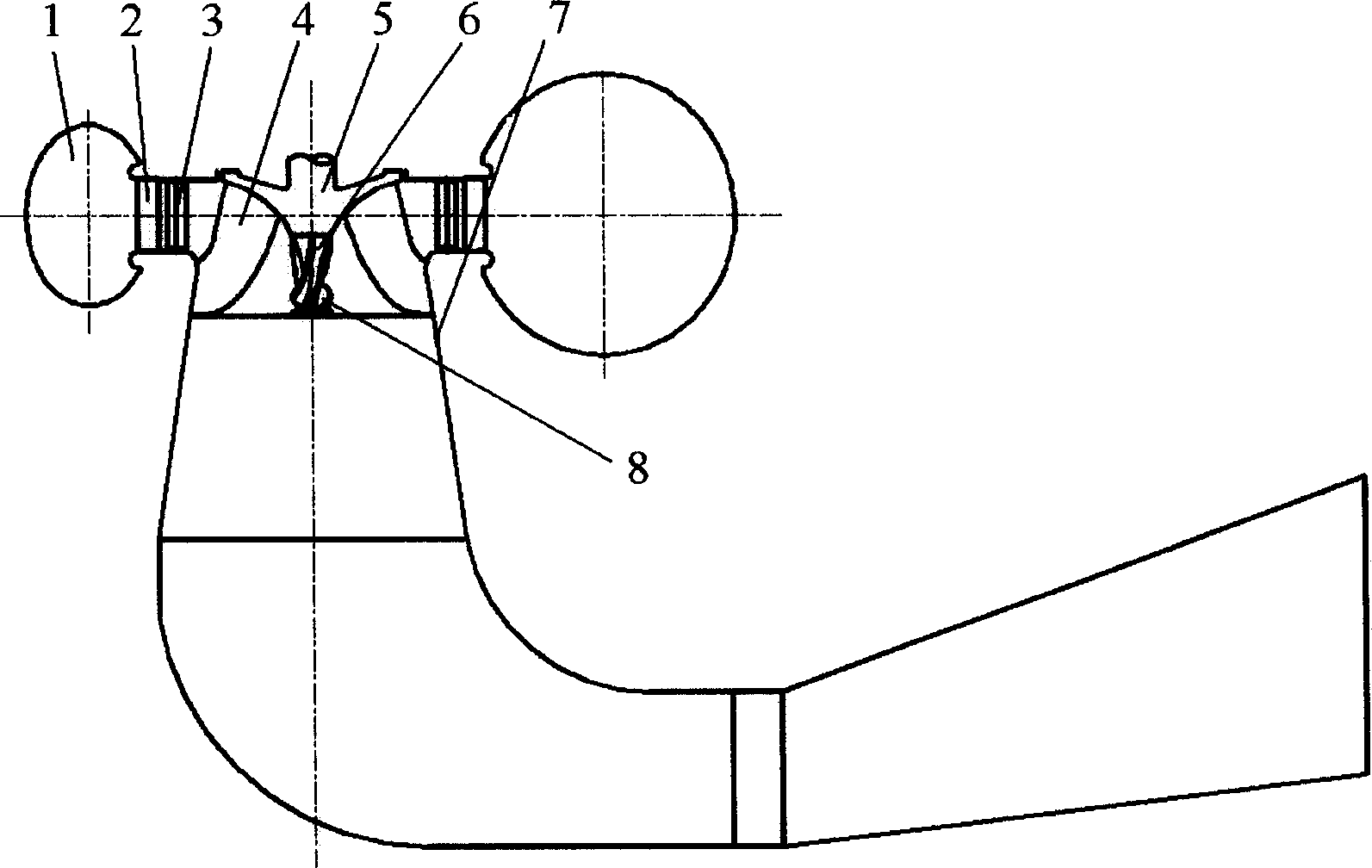

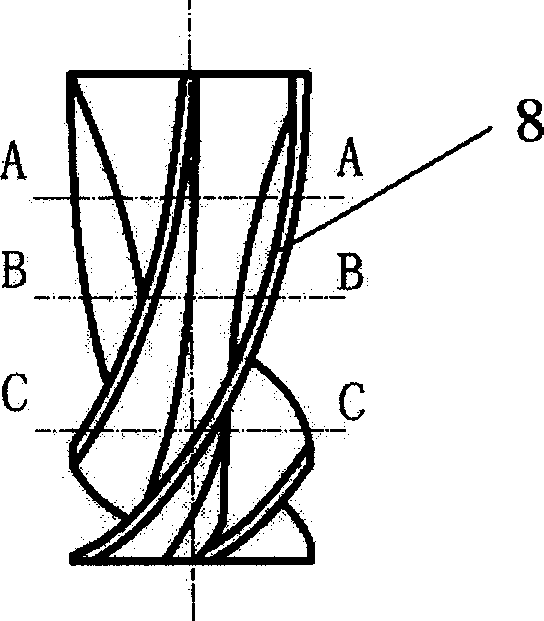

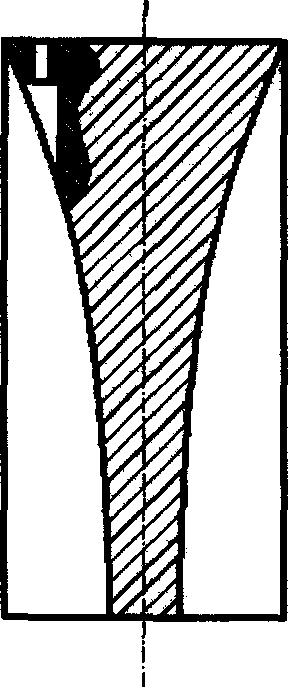

[0015] figure 1 It is a schematic structural diagram of a Francis turbine with a vortex suppression device provided by the present invention. According to the water flow direction, it includes volute 1, movable guide vane 2, fixed guide vane 3, runner 5, draft tube 7 installed at the lower part of the runner, and vortex suppression device 6; the vortex suppression device is arranged between the draft tube and the runner It is fixed on the bottom of the runner body by bolts. The vortex suppression device 6 adopts an axial-flow blade structure, and the installation angle of the inlet of the axial-flow blade 8 is the same as that of the runner blade 4; the wrap angle of the axial-flow blade 8 is 150-180 degrees, and the length is about 0.5-1.0 times the diameter. Generally, 4 to 8 axial flow blades are suitable, and their steering is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com