Water-soluble thickener and liquid acidic detergent

A technology of water-soluble thickeners and water-soluble copolymers, which is applied in the direction of inorganic non-surface active detergent compositions, organic non-surface active detergent compositions, and other chemical processes, and can solve unsatisfactory thickening effects and difficult Problems such as complete control of reaction, thickening effect of thickener, or insufficient stability over time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

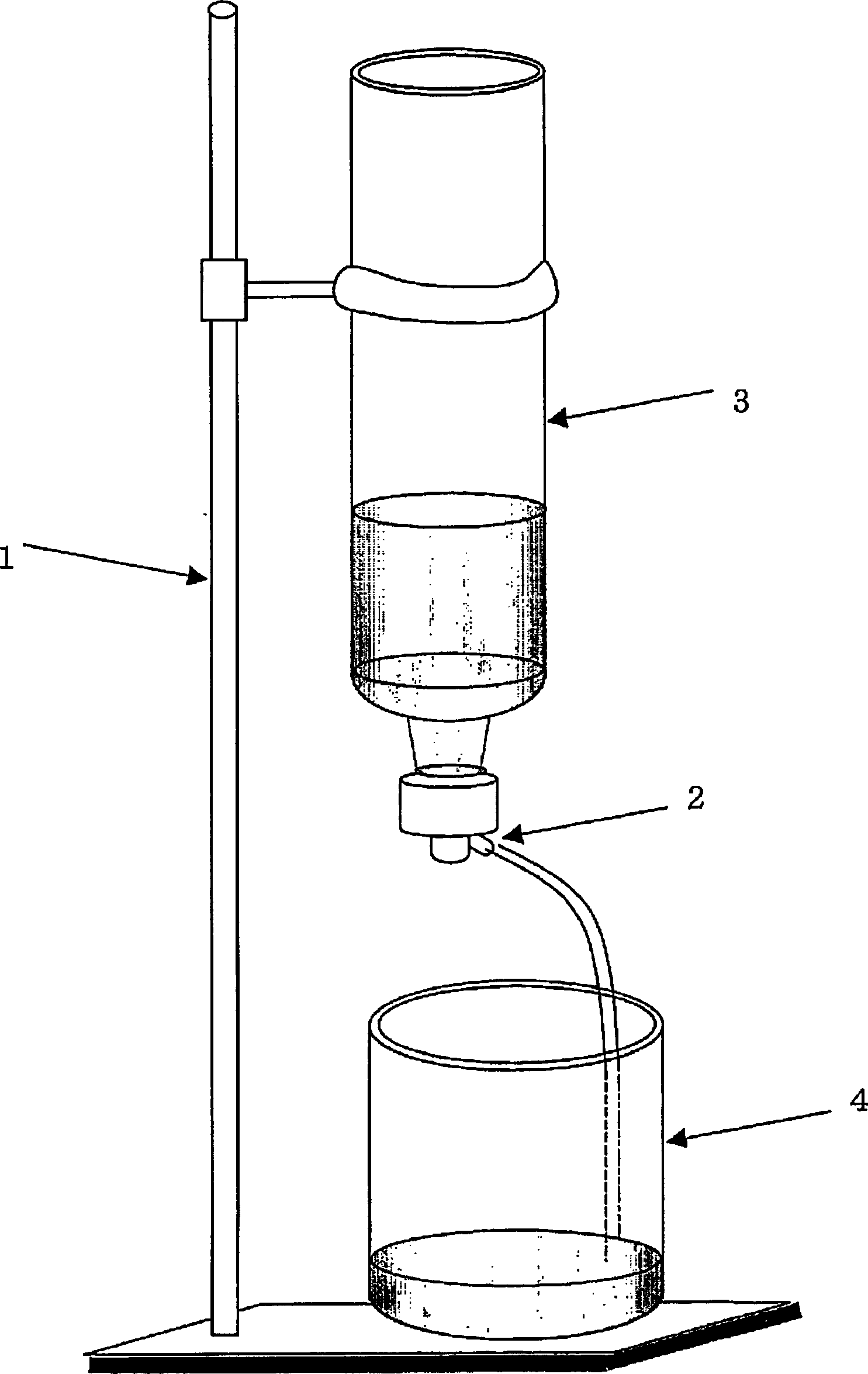

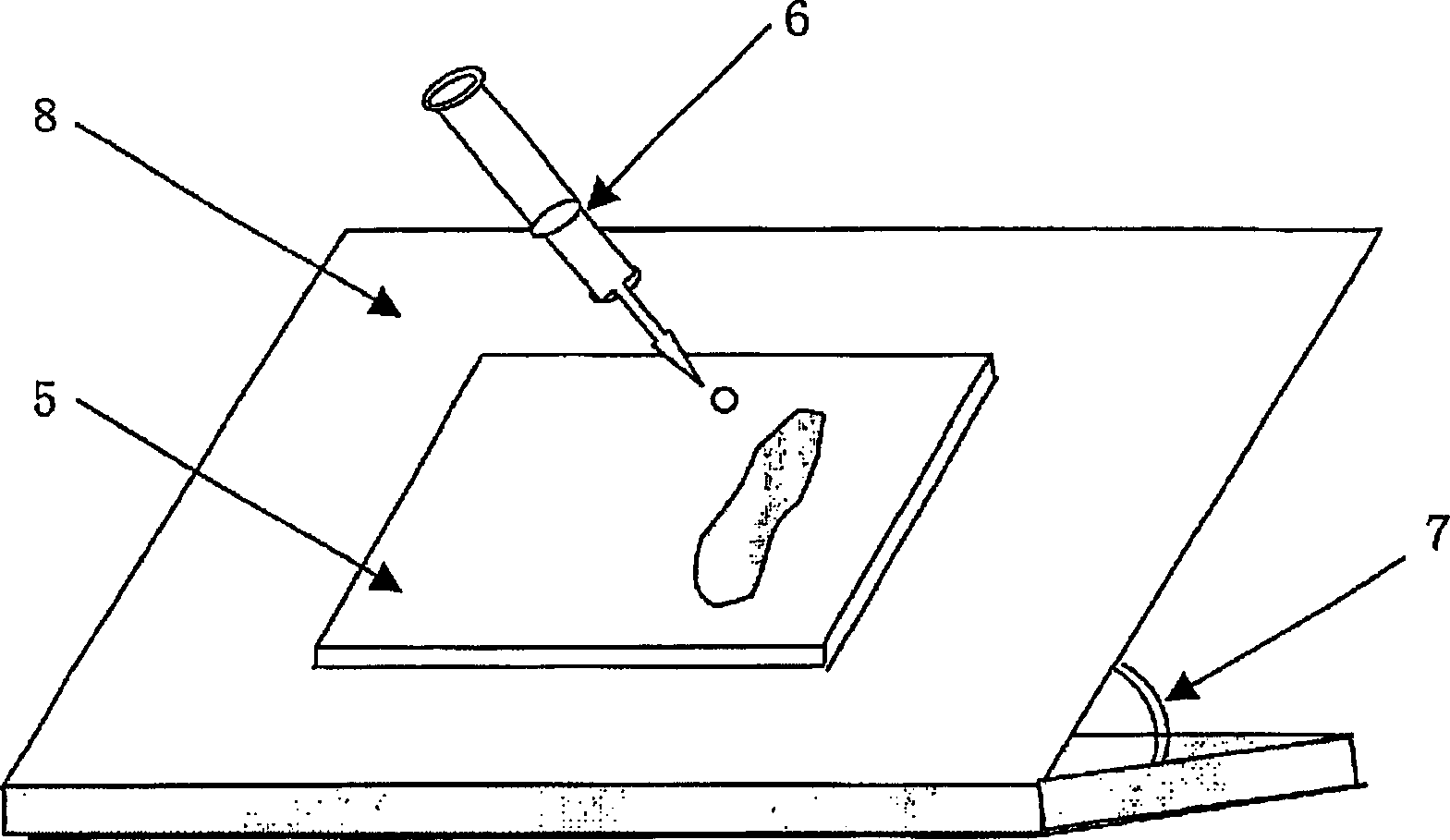

Method used

Image

Examples

Embodiment 1

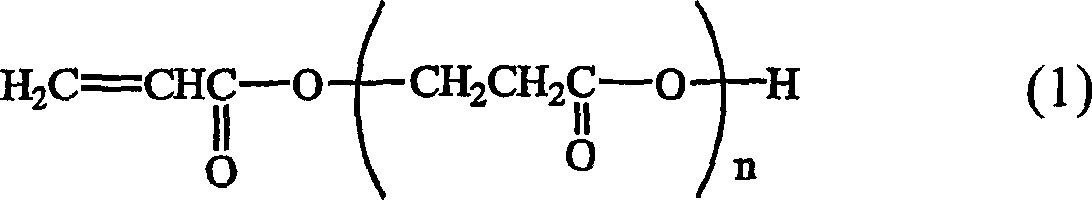

[0077] 645.9 (equivalent to 50 mol%) of 50% by weight of 2-acrylamido-2-methylpropanesulfonate aqueous solution, 184.1g (equivalent to 25% by mol) of 36% by weight of sodium acrylate aqueous solution, 50.8 g (equivalent to 25 mol%) of acrylic acid and 119.2 g of pure water were mixed to prepare 1 kg of an aqueous monomer solution having a monomer concentration of 44% by weight. The monomer aqueous solution was placed in a stainless steel Dewar vacuum flask, and the temperature in the reaction vessel was cooled to 5° C., and nitrogen gas was bubbled for 30 minutes. Then, 10 ppm (based on the total weight conversion of the monomer, the same below) of tert-butyl hydroperoxide, 200 ppm of sodium persulfate and 20 ppm of sodium erythorbate were added as polymerization initiators, and the reaction mixture was left to stand 8 hours for adiabatic static redox polymerization. After the 8-hour reaction was completed, the thus-produced hydrogel-like polymer was taken out of the reaction...

Embodiment 2

[0079] 916.8g (corresponding to 80 mol%) of 50% by weight of 2-acrylamido-2-methylpropanesulfonate aqueous solution, 65.2g (corresponding to 10 mol%) of 36% by weight of sodium acrylate aqueous solution, 18.0 g (corresponding to 10 mol%) of acrylic acid was mixed to prepare 1 kg of an aqueous monomer solution having a monomer concentration of 50% by weight. This monomer aqueous solution was placed in a stainless steel Dewar vacuum flask, and the temperature in the reaction vessel was cooled to 10° C., and nitrogen gas was bubbled for 30 minutes. Then, 30 ppm of t-butyl hydroperoxide, 200 ppm of sodium persulfate and 20 ppm of sodium erythorbate were added thereto as polymerization initiators. Carry out remaining steps in the same manner as in Example 1 to obtain the desired polymer in powder form. This polymer is designated A2.

Embodiment 3

[0081]419.4 g (corresponding to 30 mol %) of 50% by weight of 2-acrylamido-2-methylpropanesulfonate aqueous solution, 159.3 g (corresponding to 30 mol %), and 159.3 g (corresponding to 20 mole %) of 36% by weight of sodium acrylate aqueous solution, 107.7g (corresponding to 49 mole %) of acrylic acid, 5.3g (corresponding to 1 mole %) of acrylic acid dimer (product name "Aronix M-5600"; East Asia Co., Ltd.) and 308.3 g of pure water were mixed to prepare 1 kg of an aqueous monomer solution having a monomer concentration of 38% by weight. The temperature in the reaction vessel was cooled to 10°C and sparged with nitrogen for 30 minutes. Then, 30ppm (based on the conversion of the total weight of the monomer, the same below) of tert-butyl hydroperoxide, 200ppm of sodium persulfate and 20ppm of sodium erythorbate as a polymerization initiator was added thereto, and the reaction mixture was left to stand 8 hours for adiabatic static redox polymerization. After the 8-hour reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com