Application of laser emitter on CD driver

A technology of laser emission and optical drive, applied in the direction of beam source, optical recording head, etc., can solve the problems that the cost of components cannot be effectively reduced, the assembly of optical read-write head 1 is complicated, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

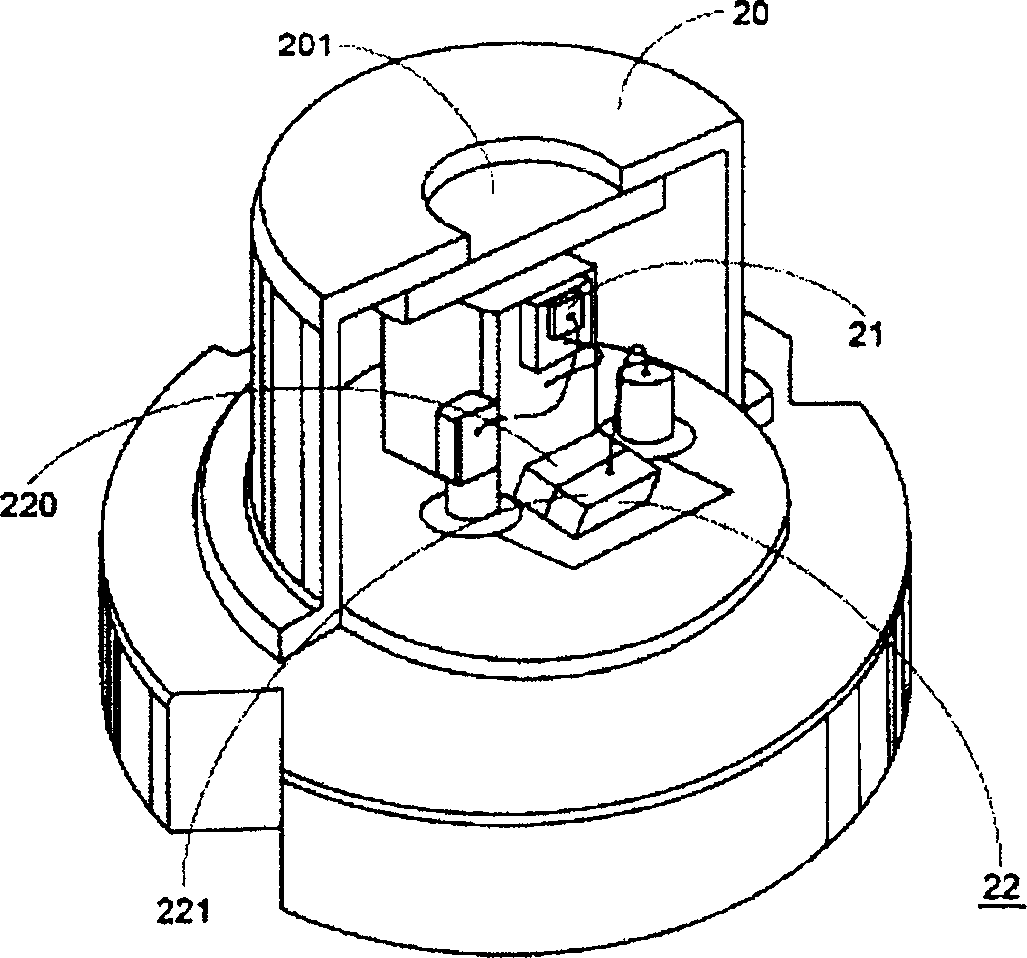

[0020] See figure 2 , which is a structural diagram of a preferred embodiment of a laser emitting device developed by the present invention to improve the defects caused by the separate arrangement of the existing semiconductor laser module 11 and the temperature sensing device 13. The laser emitting device is mainly used in an optical drive (this figure not shown in ) and an optical disc (not shown in this figure), this preferred embodiment mainly includes a casing 20, which is arranged in the optical pickup head of the optical drive or in the optical pickup head, the casing The body 20 also has a light-transmitting part 201, and the laser emitted by the laser emitting component 21 that can be completed by a laser diode is transmitted through the light-transmitting part 201, and the feature of this embodiment is that the light detecting component 220 and the temperature sensing component 221 is mainly completed simultaneously on a silicon substrate 22 by a CMOS process. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com