Chemical-adding, coagulating and precipitating + ABR reactor + aerobic fluidized bed for treating industrial waste water

An aerobic fluidized bed, coagulation and sedimentation technology, used in energy wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

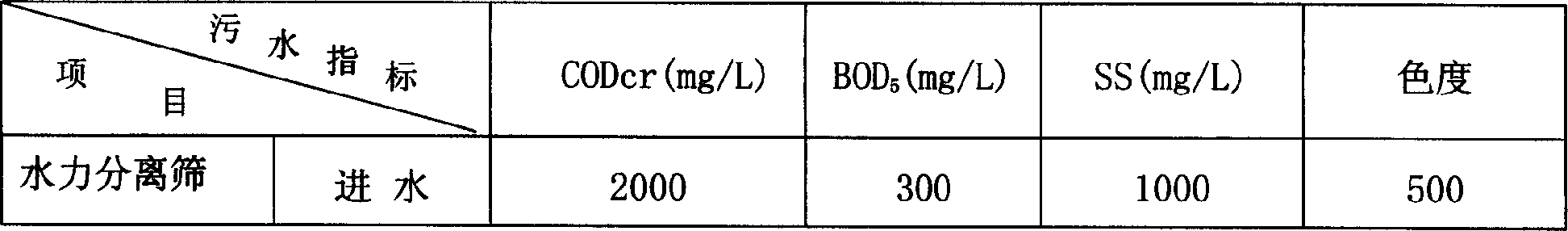

[0034] The core process unit of the process is the ABR reactor and aerobic fluidized bed. In view of the characteristics of printing and dyeing and tanning wastewater, all printing and dyeing and tanning enterprises are required to discharge batik wastewater, high-alkalinity wastewater, and three types of wastewater before the wastewater is discharged into the sewer. Wastewater with high chromium, sulfide content or other toxic and harmful pollution indicators in the biochemical process of the sewage treatment plant shall be effectively pre-treated to reach the sewage treatment plant's required discharge index value. The specific process flow of the sewage treatment plant is as follows:

[0035] Raw water → pH adjustment tank → adjustment tank → lift pump → mechanical hydraulic separation screen → (dosing) → coagulation sedimentation tank → ABR hydrolysis (acidification) tank → aerobic biological fluidized bed → sedimentation tank → oxidation contact tank → discharge

[0036] A br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com