Crude oil full-fraction one-stage reduced pressure distillation process

A whole distillate and crude oil technology, which is applied in the field of hydrocarbon oil distillation, can solve the problems of high energy consumption and complicated process flow, and achieve the effects of high heat exchange efficiency, advanced technology, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

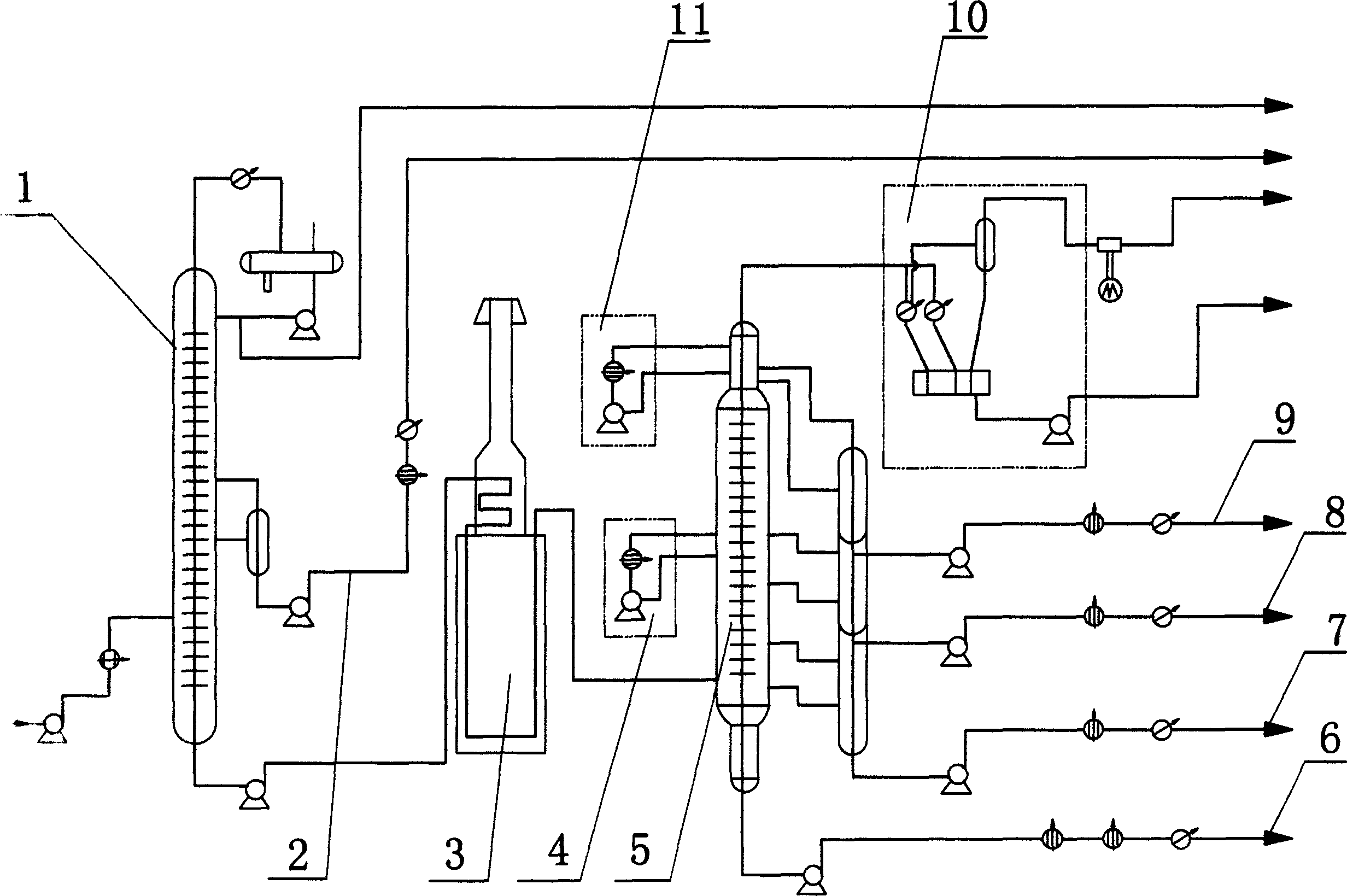

[0016] Crude oil is firstly desalted and dehydrated and then heat-exchanged to 280-300°C before entering the initial distillation tower 1. Straight-run gasoline or reforming raw materials can be obtained at the top of the initial distillation tower. 200# solvent oil side line or kerosene side line can be set up on the side of the tower according to needs 2. The oil extracted from the bottom of the initial distillation tower 1 enters the heating furnace 3, and after being heated to 400-410° C., it is sent into the vacuum tower 5 for vacuum distillation. No product is produced at the top of the decompression tower, and the top of the decompression tower is directly connected with the vacuum equipment 10 . A top circulation reflux system 11 and a middle section circulation reflux system 4 are respectively arranged at the top position and the middle position of the decompression tower 5 . The purpose of the circulating reflux system is to balance the load in the decompression tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com