Heat-accumulating type metal magnesium reduction stove

A reduction furnace and metal magnesium technology, applied in the field of new high-efficiency regenerative metal magnesium reduction furnace, can solve problems such as pollution, heat waste, and low combustion efficiency, and achieve the effects of saving furnace space, prolonging life, and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

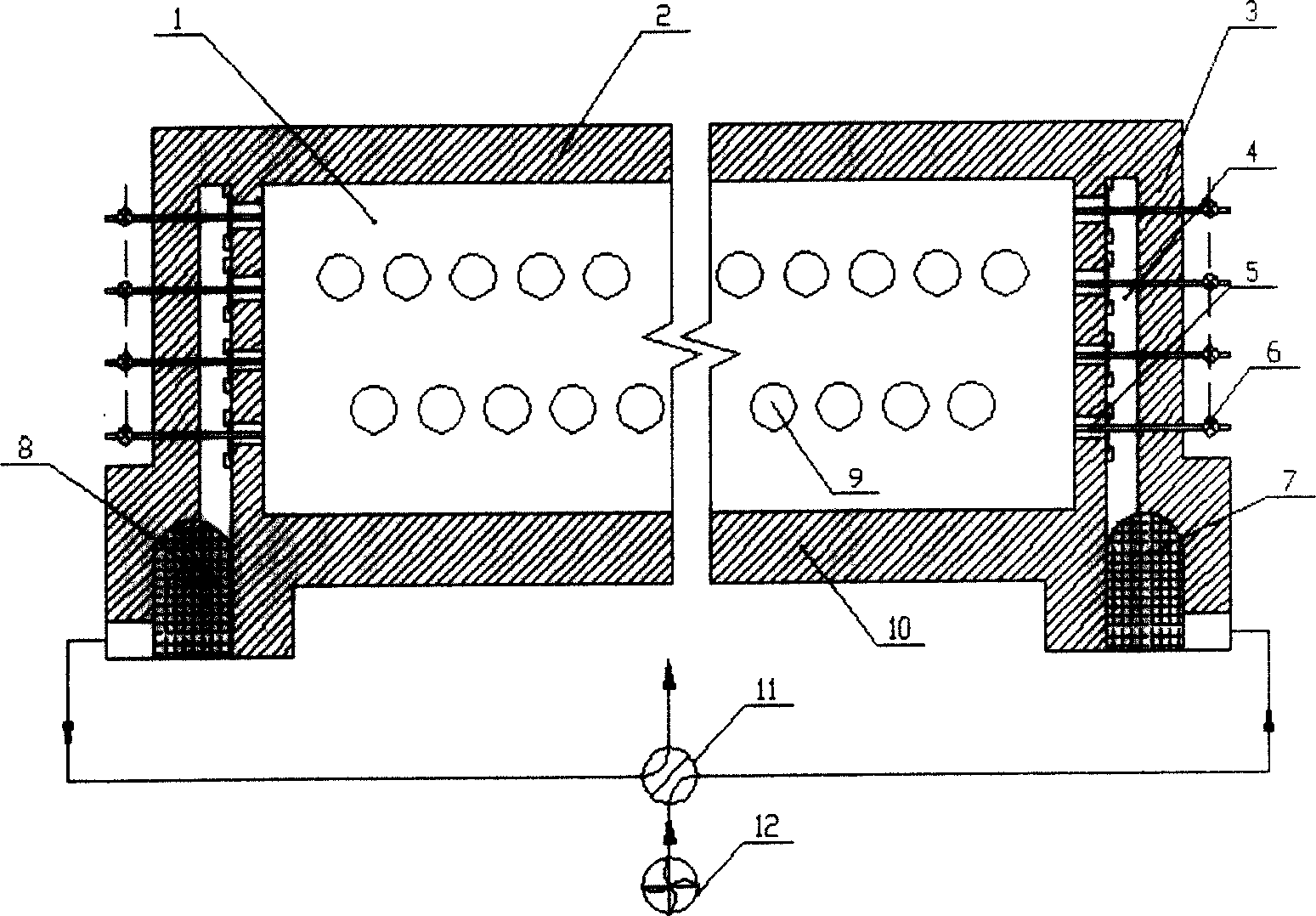

[0009] Two sets of regenerators (group A and group B) are arranged at the bottom of the walls at both ends of the reduction furnace, and the interior is filled with a new type of regenerator—ceramic honeycomb or ceramic pellets. During normal operation, the regenerators of group A release heat and heat the air flowing through the regenerators of group A; at this time, the regenerators of group B absorb heat and recover the sensible heat of the flue gas flowing through the regenerators of group B. After a reversing cycle, the regenerators of group A absorb heat and the regenerators of group B release heat. In this way, the two regenerators can alternately switch working states to recover the waste heat in the high-temperature flue gas. 2-40 burners are arranged symmetrically on the walls at both ends of the reduction furnace. During normal operation, the fuel is supplied from the burner on one side, and the flue gas is discharged from the burner on the other side, and the direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com