Nano grade positioning precision one dimension displacement work table

A positioning accuracy and workbench technology, which is applied in the direction of manufacturing tools, large fixed members, metal processing equipment, etc., can solve the problems of difficult installation in compliance with the Abbe principle, small positioning accuracy working range, slow positioning speed, etc., and meet the requirements of the operating environment Low, high positioning accuracy, fast positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

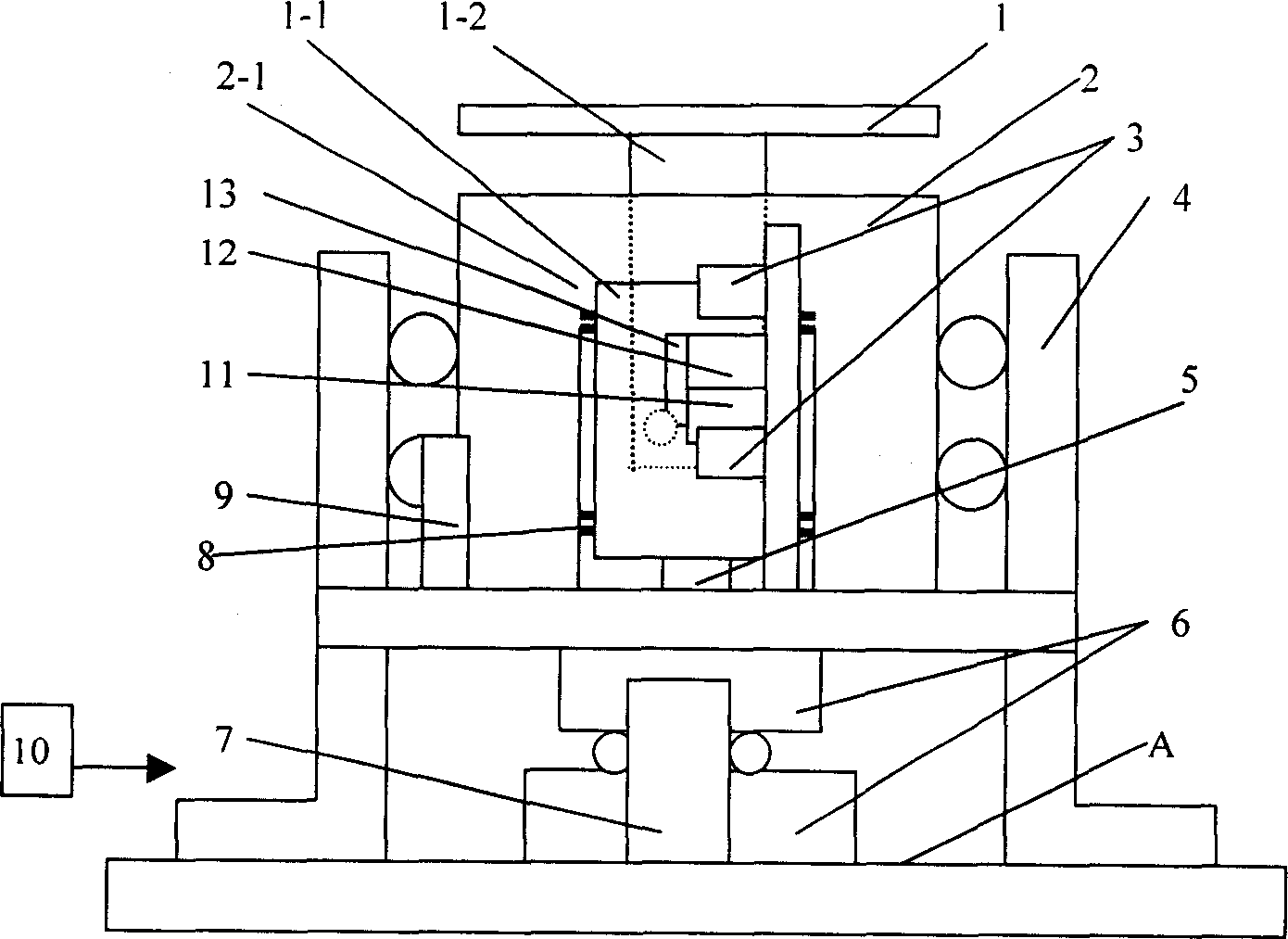

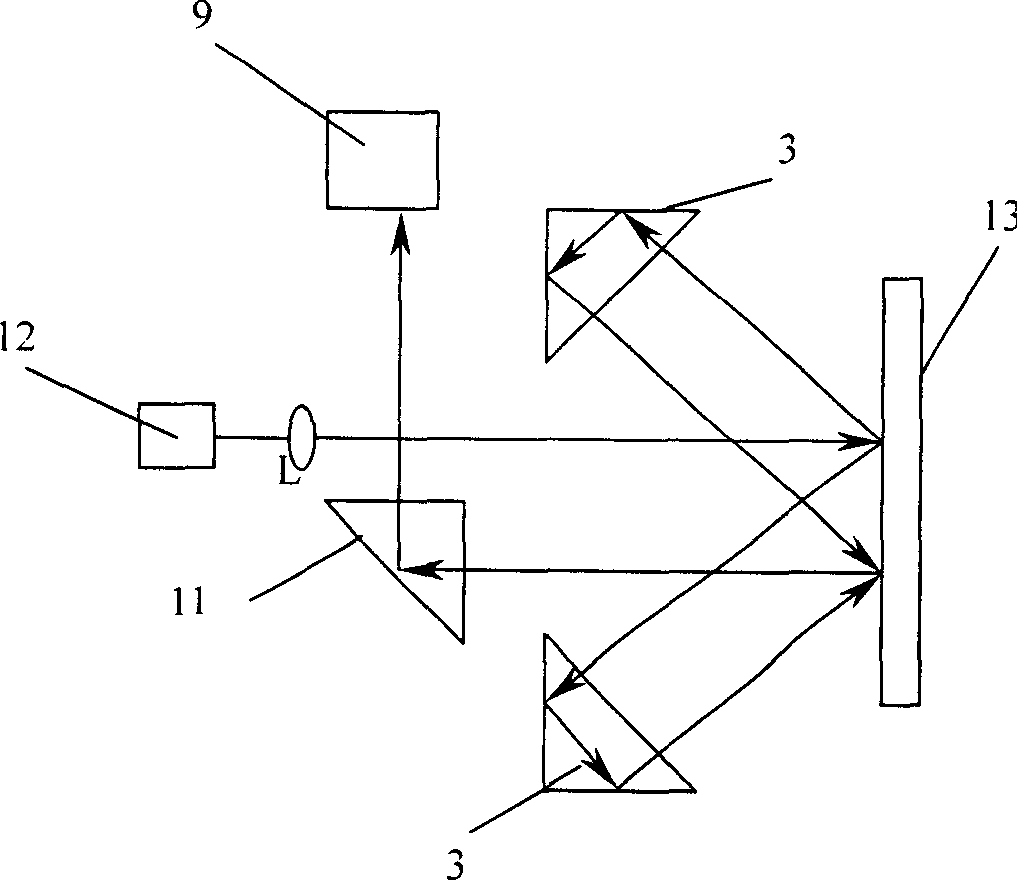

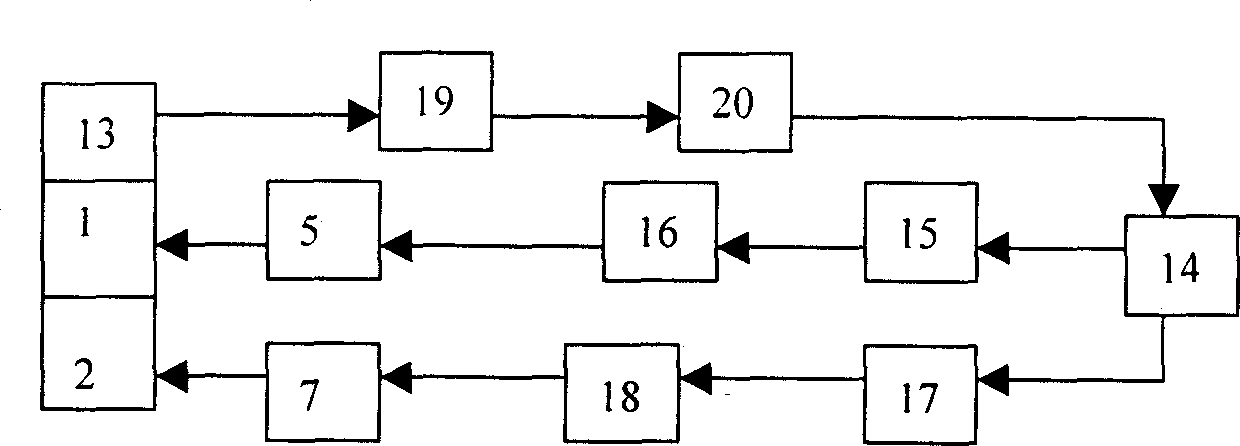

[0017] Workbench of the present invention such as figure 1 As shown, it includes the table part, the position detection part, the signal processing and control circuit part and the drive part. The workbench part includes a rough positioning workbench 2 and a fine adjustment and positioning workbench 1. The rough positioning workbench 2 is placed in the middle of the rolling guide rail 4 in the vertical direction, and the coarse displacement adjustment mechanism 6 is located below the rough positioning workbench; the fine adjustment and positioning work The base 1-1 of the table 1 is placed in the inner cavity 2-1 of the rough positioning workbench, and the base 1-1 is connected with the inner cavity 2-1 of the rough positioning workbench through four symmetrical folding flexible hinge mechanisms 8 . Between the base 1-1 of the fine adjustment and positioning workbench and between the rough positioning workbench is a piezoelectric micro-displacement device 5 as a fine displacem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com