Man machine alternating system of full digitalization hidder arc wolding

A human-computer interaction, all-digital technology, applied in the field of control systems in the field of welding technology, can solve the problems of one-time call-out, inability to adjust and control, human-machine interface upgrades and digital limitations, etc., to achieve convenient adjustment, efficient human The effect of computer interaction system function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

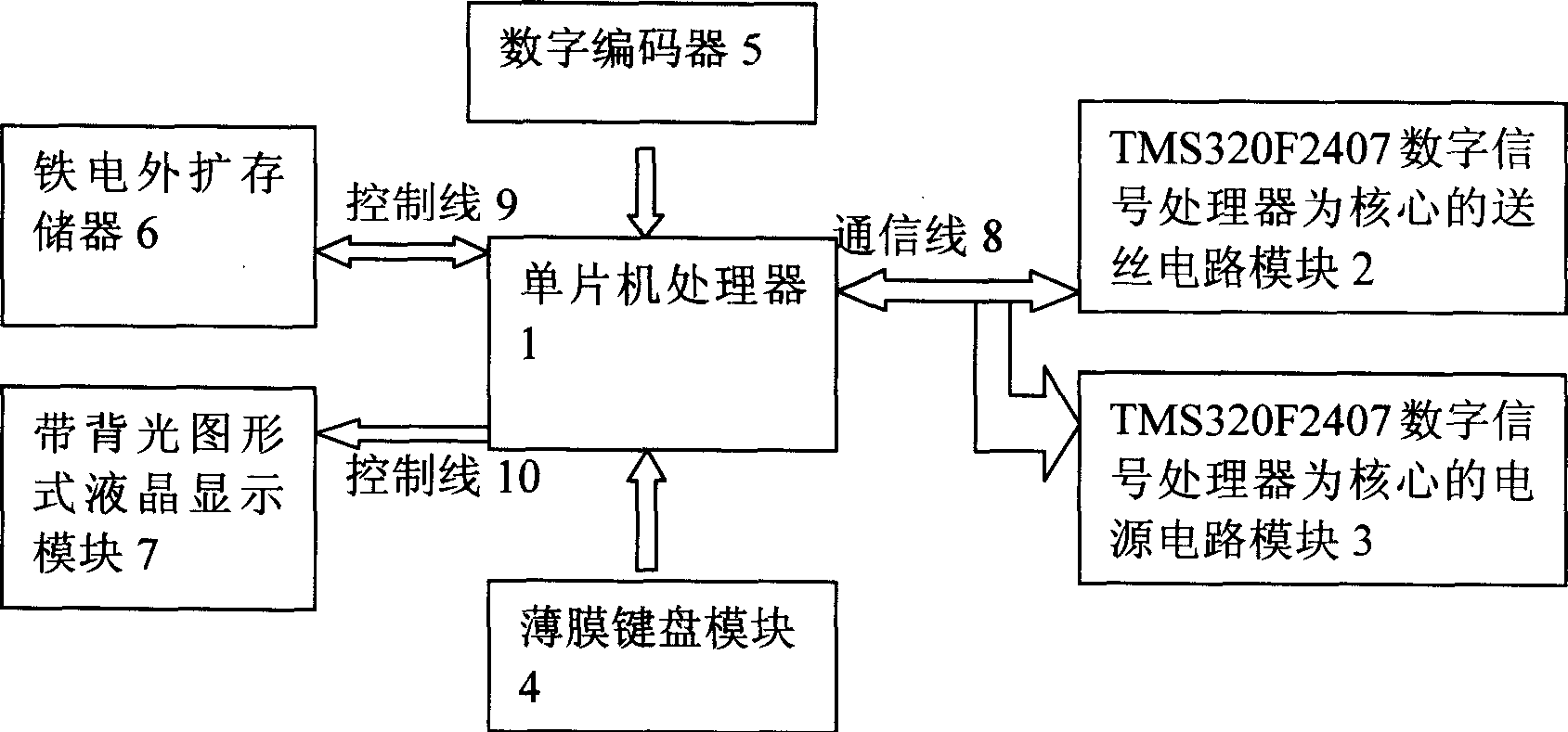

[0014] The present invention uses the wire feed module 2 and power supply module 3 with the digital signal processor TMS320F2407 of Texas Instruments as the core, and the TMS320F2407 as the digital signal processor. It has the characteristics of strong data processing ability and high speed. It adopts the pipeline bus form 16-bit fixed-point and 32-bit floating-point digital signal processor; 64K-bit non-volatile ferroelectric random access memory from Shenzhen Huazhu Technology Company, namely the external extended memory of ferroelectric FM24C64. FM24C64 has a structure capacity of 8,192*8 bits , High-endurance read and write times, power-off data retention for 45 years, bus speed can reach 1MHZ; SED1335 with backlight graphic LCD module 7, SED1335 is a LCD controller produced by Japan's SEIKO EPSON company, it is in the same category It is the most powerful, and its features: a powerful I / O buffer; rich command functions; four-bit data parallel transmission with a maximum drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com