Preparation method of organic electro luminous material rare earth europium organic metal complex

A technology of electroluminescent materials and organic metals, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of high color purity, low purity, high cost, etc., and achieve the effect of simple process, good purity and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

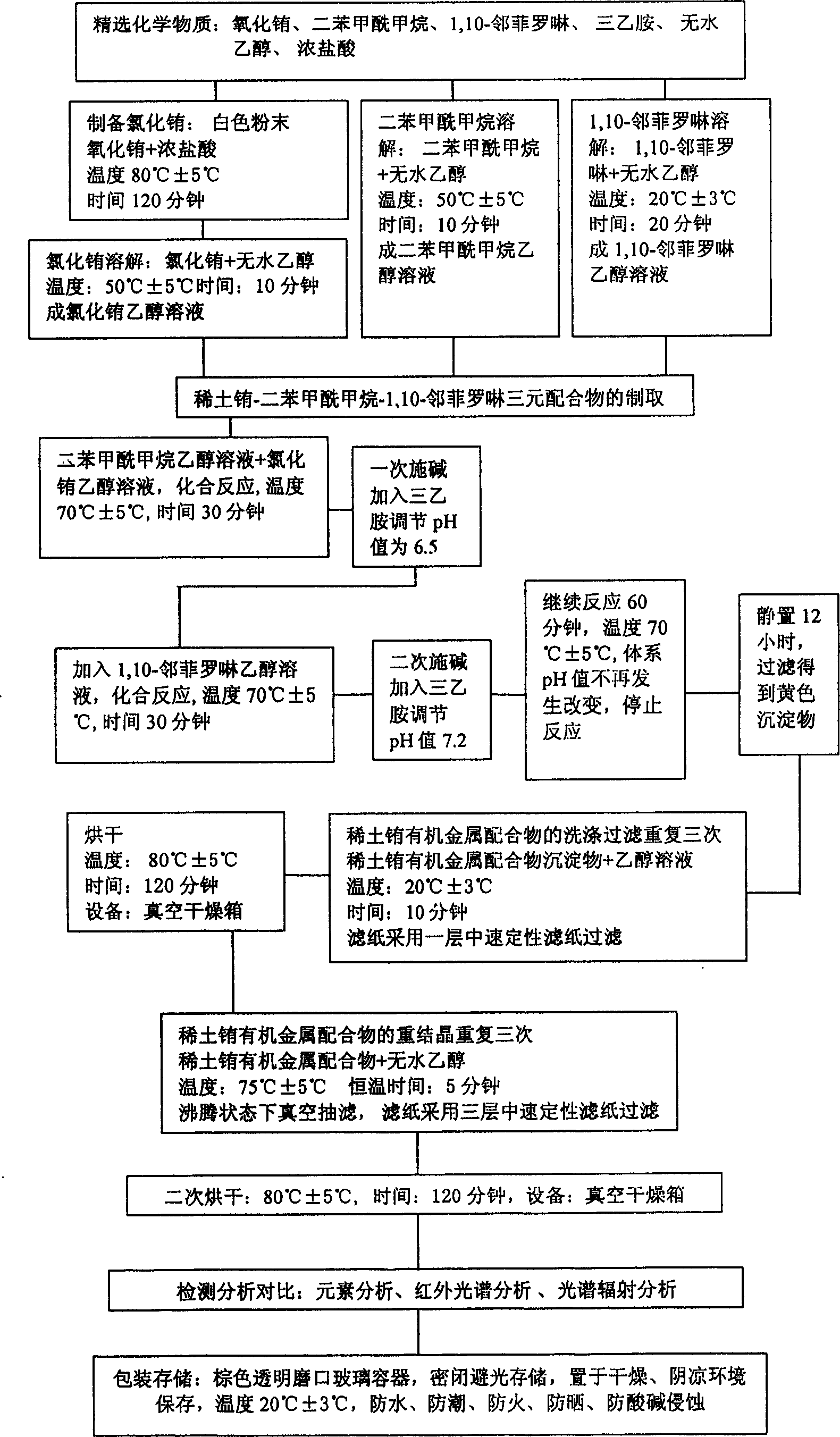

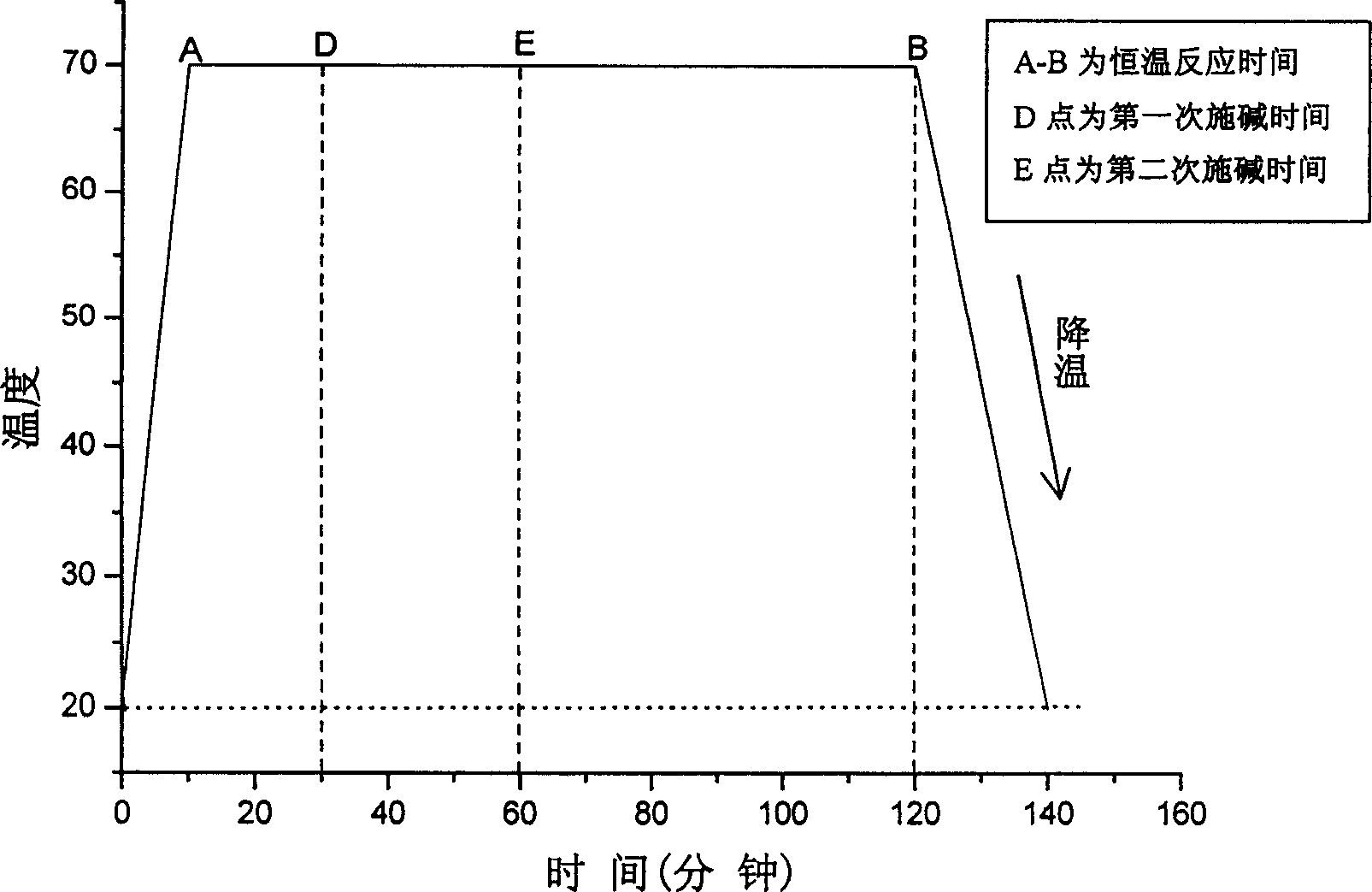

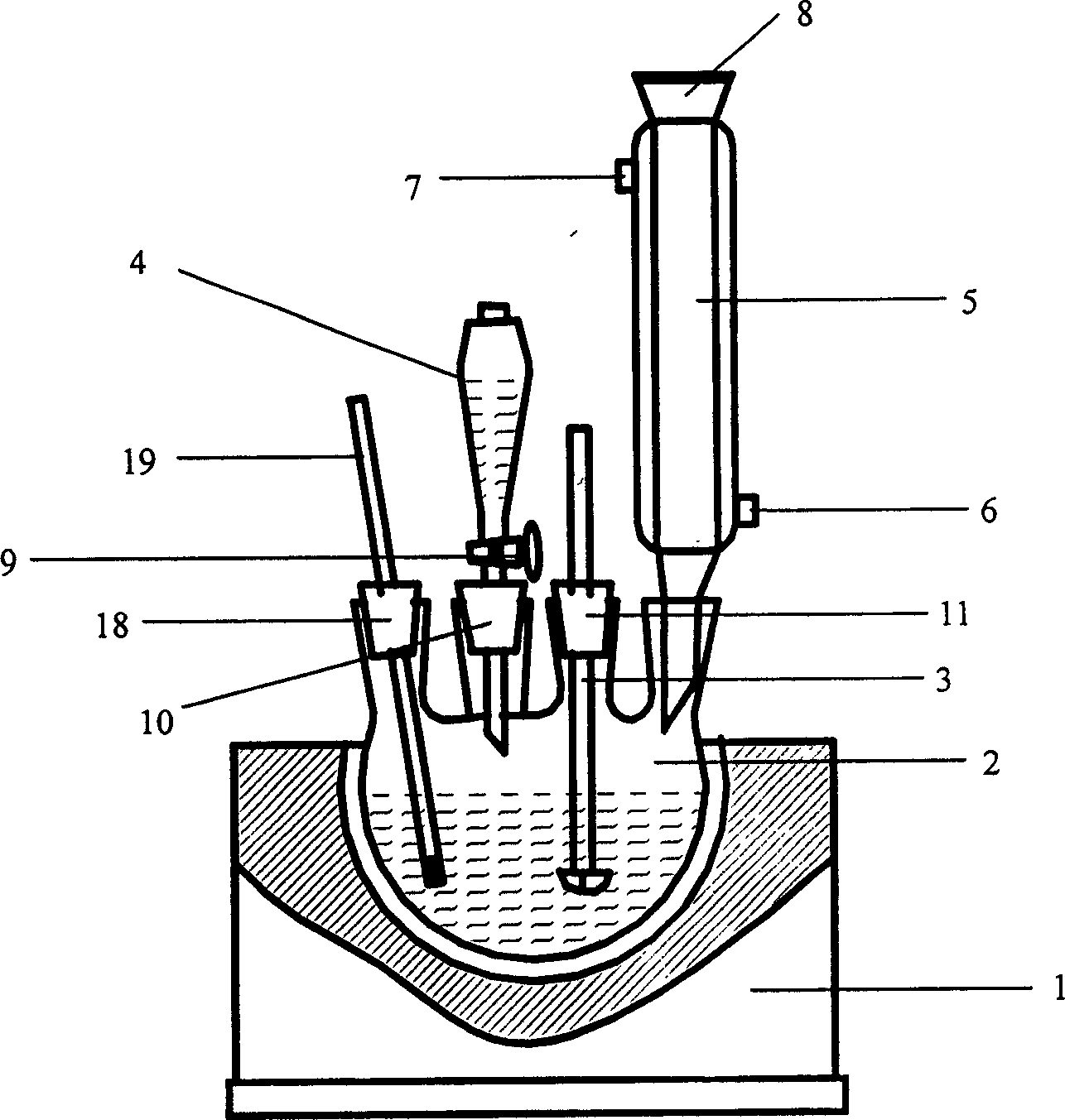

[0084] The present invention will be further described below in conjunction with accompanying drawing:

[0085] figure 1 Shown is the process flow chart for preparing rare earth europium organometallic complexes, which must be carried out in strict accordance with the process flow and process values, and operate in sequence.

[0086] The chemical substances required for the preparation must be strictly selected, and the purity control must be carried out to avoid the intervention of too many impurities and prevent side reactions, so as not to affect the luminescence performance of the product.

[0087] The chemical substances used in the compound reaction must be accurately weighed with an electronic scale in strict accordance with the ratio to ensure that the compound reaction is accurately compounded according to the molar ratio, optimize the reaction parameters, and avoid waste.

[0088] When preparing europium chloride, europium oxide and excess concentrated hydrochloric ...

Embodiment 1

[0104] All production equipment is in ready working condition;

[0105] Preparation of europium chloride: Weigh 0.5 g of europium oxide and place it in a round-bottomed crucible, add 15 ml of concentrated hydrochloric acid, place the round-bottomed crucible on an electric heating mantle and heat at a temperature of 80°C±5°C for 120 minutes, stirring evenly , the solution was clarified, and the concentrated hydrochloric acid was evaporated to obtain a white europium chloride powder;

[0106] Dissolve Europium Chloride:

[0107] Put the white europium chloride powder in a beaker, add 20 ml of absolute ethanol, heat with an electric heating mantle for ten minutes, and stir at 50°C±5°C to form a europium chloride ethanol solution;

[0108] To dissolve dibenzoylmethane:

[0109] Weigh 1.884 g of diphenylmethane, put it in a beaker, add 80 ml of absolute ethanol, heat the beaker on an electric heating mantle at a temperature of 50°C±5°C, and stir for 10 minutes while heating until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com