Metal corrosion preventing method in water environment

A metal anti-corrosion and water environment technology, applied in the field of metal anti-corrosion, can solve the problems of metal corrosion and the inability of anti-corrosion methods to achieve cost and utility, and achieve the effect of preventing corrosion, facilitating promotion and application, and achieving good effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

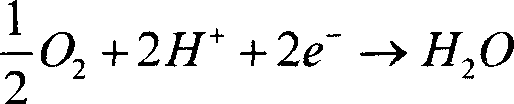

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Weigh 3 parts of 100 mg of activated carbon fiber, spread out and place them flat in beakers filled with 200 ml of tap water with a pH of 4, 7 and 10 respectively.

[0019] After derusting and polishing 6 groups of iron sheets (5 pieces in each group), they were weighed in groups, and 3 groups were scattered in the above-mentioned 3 kinds of water samples, and the other 3 groups were placed in the pH without adding activated carbon fiber. 4, 7 and 10 in 200ml of tap water.

[0020] After soaking for one week, the iron sheets of each group were taken out, derusted and weighed. The results are shown in Table 1.

[0021] The results showed that under neutral conditions, the static corrosion rate of iron sheets was effectively reduced in a wide range of pH 4-10 after the addition of activated carbon fibers.

[0022] pH

4

7

10

Corrosion rate of iron sheet

(%)

Add activated carbon fiber

0.121

0.119

0.093

...

Embodiment 2

[0026] Embodiment 2 (dynamic corrosion of iron sheet)

[0027] (Blank test) Take a group of iron sheets (88-89g), weigh them after derusting and polishing, and perform dynamic corrosion. After 1 week, the iron sheet was taken out, and the surface was derusted before weighing.

[0028] Put 100 mg of activated carbon fiber into the filter tube of the dynamic corrosion test device as the filter material, follow the steps of the above blank test, and compare the results with those of the blank test, as shown in Table 3.

[0029] blank

activated carbon fiber

Corrosion reduction

(%)

Corrosion rate of iron sheet (%)

0.141

0.050

64.54

[0030] It can be seen from Table 3 that compared with the results of the blank test, it is found that the activated carbon fiber can effectively reduce the amount of corrosion by about 64%.

[0031] Combined with the static test results under the same additive conditions, it can be found t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com