Hot melt adhesive composition based on a random copolymer of isotactic polypropylene

A technology for hot melt adhesives and compositions, applied in the directions of adhesives, fabrics, textiles, etc., can solve the problems of lack of flexibility and toughness, poor impact resistance, poor strength, etc., and achieve low curing shrinkage and complete compatibility. performance, good balance of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0127] Hot Melt Adhesive Examples 1-4 shown in Table 2 were prepared using the ingredients and mixing procedure described above. The examples had a total weight of 2000 grams and were mixed in a laboratory mixer at 350-375°F in a carbon dioxide atmosphere consisting of a motorized stirring blade, a heating mantle, a temperature control unit, and approximately 1 gallon of Container composition. In addition to the mRCP copolymer, appropriate amounts of each ingredient calculated in the ratios in the table below were added to the container. The temperature of the vessel is then raised to melt the contents. After the ingredients in the container are completely molten, start the motor to start stirring. Next, add the mRCP copolymer ingredients and mix well in the vessel. Adhesive Examples 1-4 are particularly suitable for use as elastic attachment adhesives for elastic attachments.

[0128] Examples 1-4 were subjected to Brookfield viscosity, ring and ball softening point and c...

Embodiment 5-7

[0131] Examples 5-7 were prepared following the same procedure as above using the ingredients listed in Table 3. These formulations are particularly suitable as adhesives for various flexible packaging applications and as structural adhesives for disposable nonwoven applications. Peel strength is the most important parameter of adhesive performance when used. The peel strength of Examples 5-7 was measured and the results are reported in Table 3. Using a CT225 hot melt applicator equipped with three ITW controlled fiberization nozzles, the same polyethylene film and polypropylene spunbond nonwoven as in Examples 1-4 were laminated using the spiral spray technique, and prepared for peel strength. Measured samples. At 4 g / m at 300°F coating temperature and 0.5 second open time 2 amount of adhesive applied. The adhesives of Examples 5-7 were found to have little or very low room temperature tack, low melt viscosity, good sprayability and good film / nonwoven tack.

[0132] ...

Embodiment 8-9

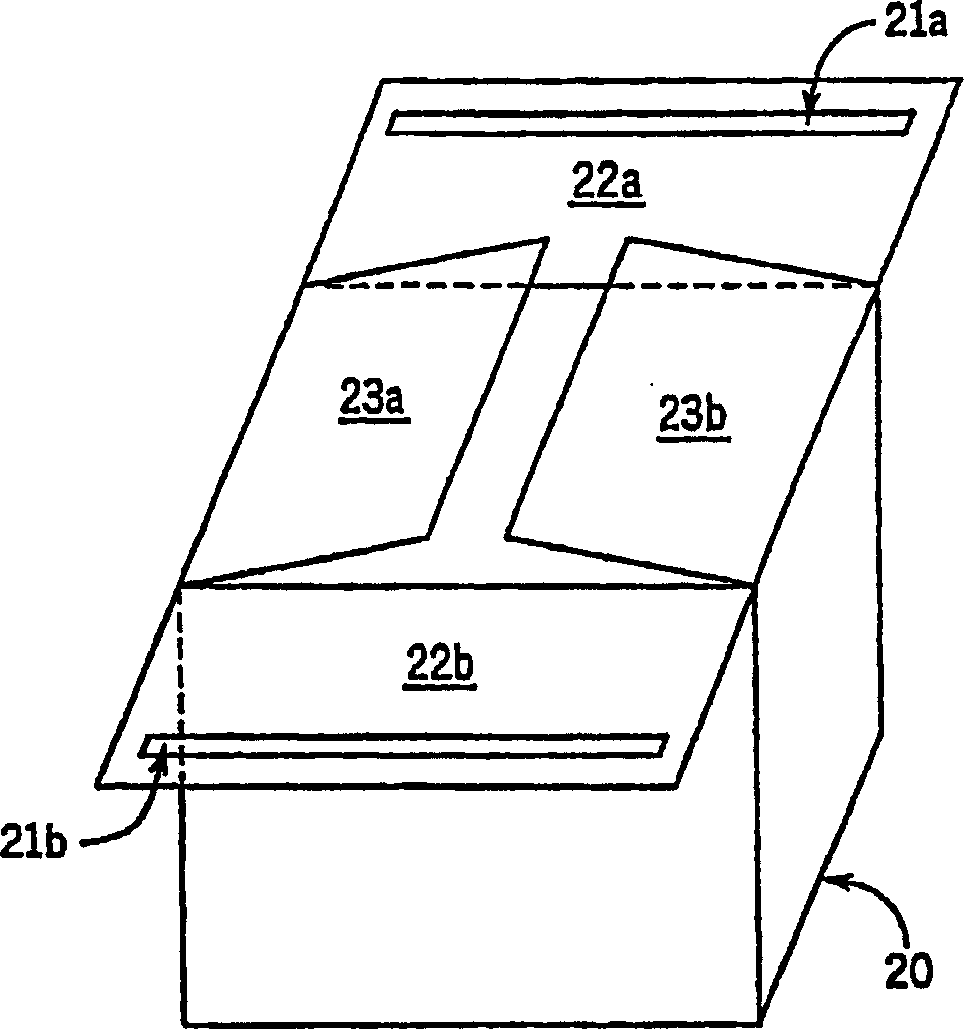

[0134] Using the ingredients listed in Table 4, the hot melt adhesives of Examples 8-9 were prepared in the same procedure as above. In Examples 8 and 9, wax (Marcus 300) was included in the adhesive to replace the APAO component in the above formulation. Therefore, the binders of Example 8 and Example 9 do not contain APAO. The total amount of each example is 250 grams, mixed at 350°F under CO 2 in the atmosphere. They are especially suitable for box and case sealing applications. To illustrate this application, refer to figure 2 and image 3 ,Such as figure 2 21a and 21b, single adhesive beads (single adhesive beads) with a diameter of about 2 mm were manually applied to the upper surface of the upper flaps 22a and 22b of the corrugated box 20 . Immediately after the adhesive is applied, the upper flaps 22a and 22b of the carton 20 are folded and brought into contact with the lower flaps 23a and 23b to seal the carton 20 . Then, the flaps 22a, 22b, 23a and 23b are f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com