Thermostatic control system for instruments

A technology for constant temperature control and instrumentation, which is applied in the direction of temperature control, instruments, and instrument parts by electric means, and can solve problems such as reducing the reliability and safety of equipment use, easy aging and deterioration of the insulating sheath of wires, and short circuits. , to achieve the effect of increasing the ambient temperature range, improving the temperature display and control accuracy, and reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

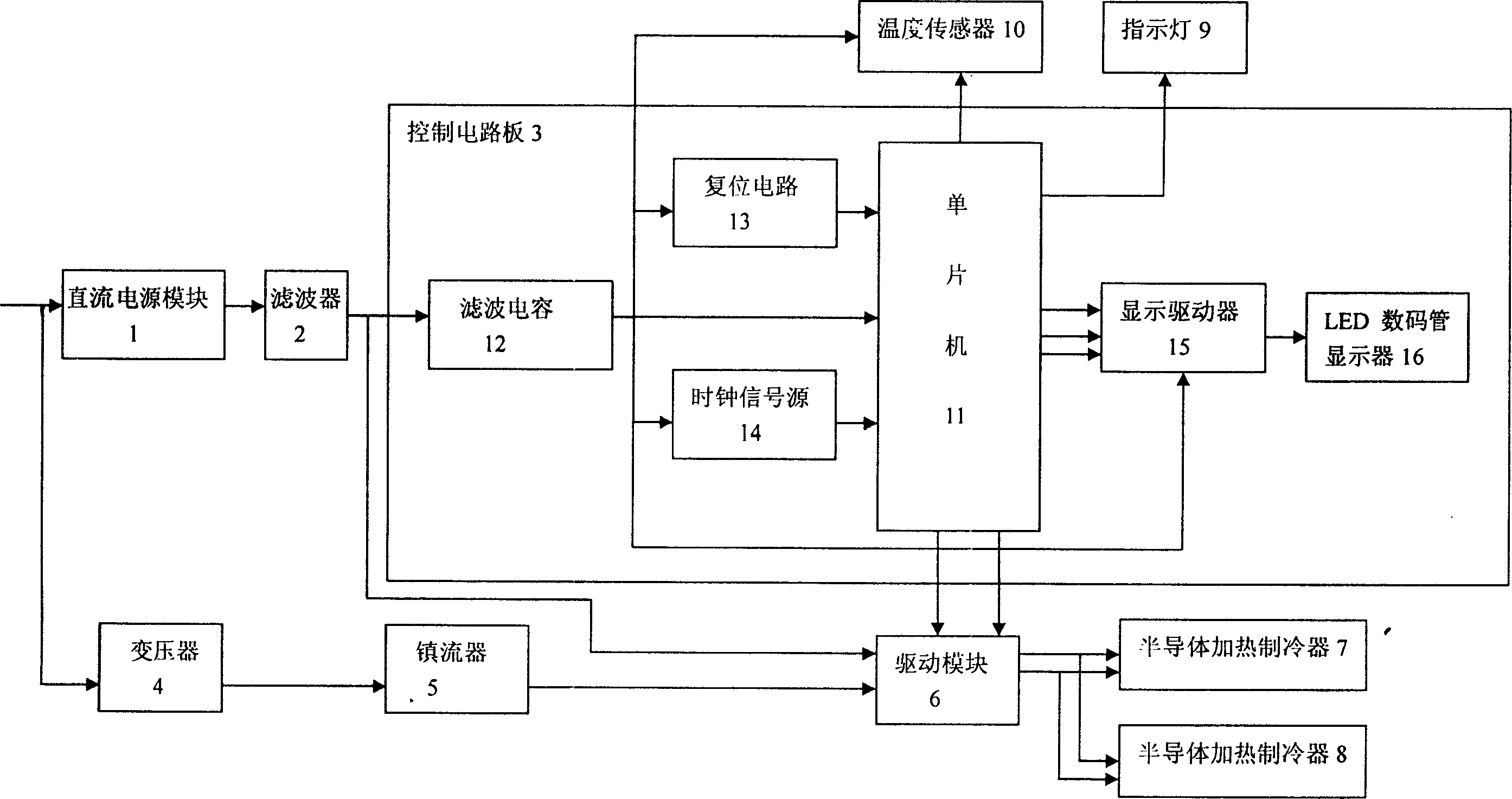

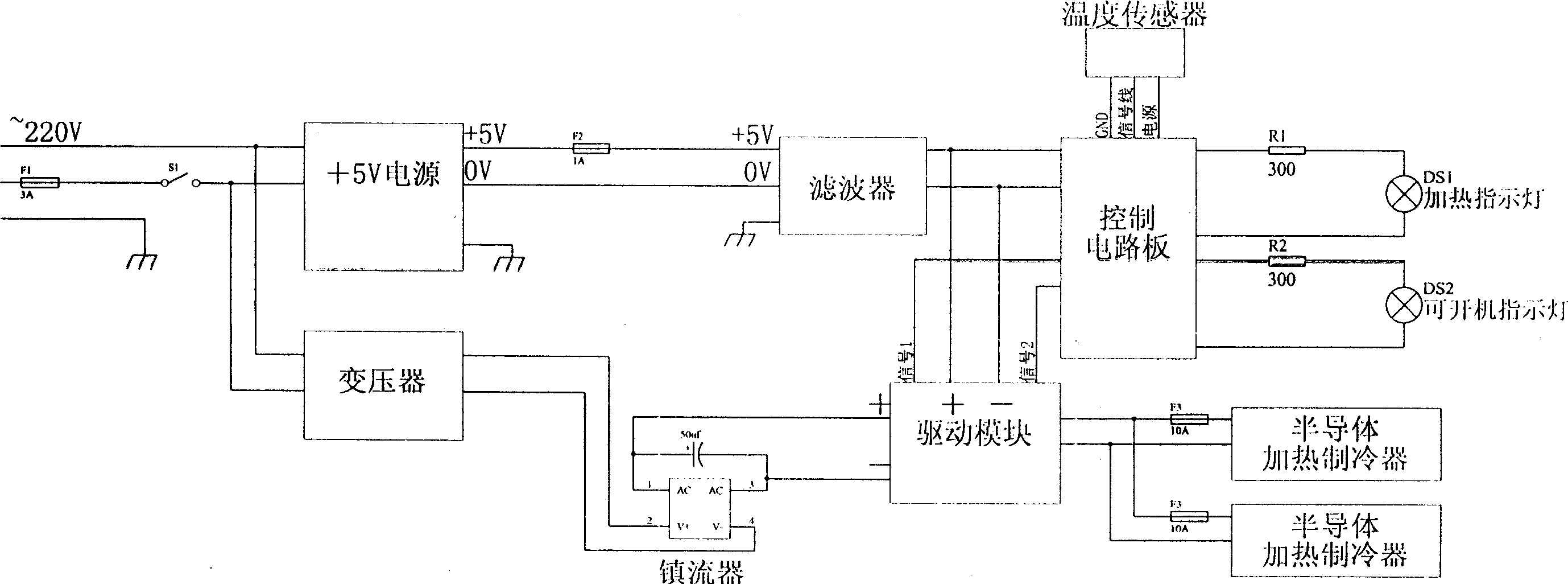

[0027] The present invention includes a DC power supply module 1 , a filter 2 , a control circuit board 3 , a transformer 4 , a ballast 5 , a drive module 6 , semiconductor heating refrigerators 7 and 8 , an indicator light 9 , and a temperature sensor 10 . like figure 2 The shown DC power supply module 1 adopts 4N1C-X5 type 5V / 1A power conversion module, filter 2 adopts model DL-2D1, transformer 4 adopts 220V AC voltage to convert 12V AC voltage, current 18A transformer, and ballast 5 KBPC3510W is adopted, and the drive module 6 is a motor drive module satisfying 30A, 250V, 50 / 60HZ. In order to increase heat dissipation and cooling area, the semiconductor heating refrigerators 7 and 8 are respectively inlaid on two aluminum plates with good thermal conductivity, and the temperature sensor 10 is a single-wire digital temperature sensor whose model is DS18B20.

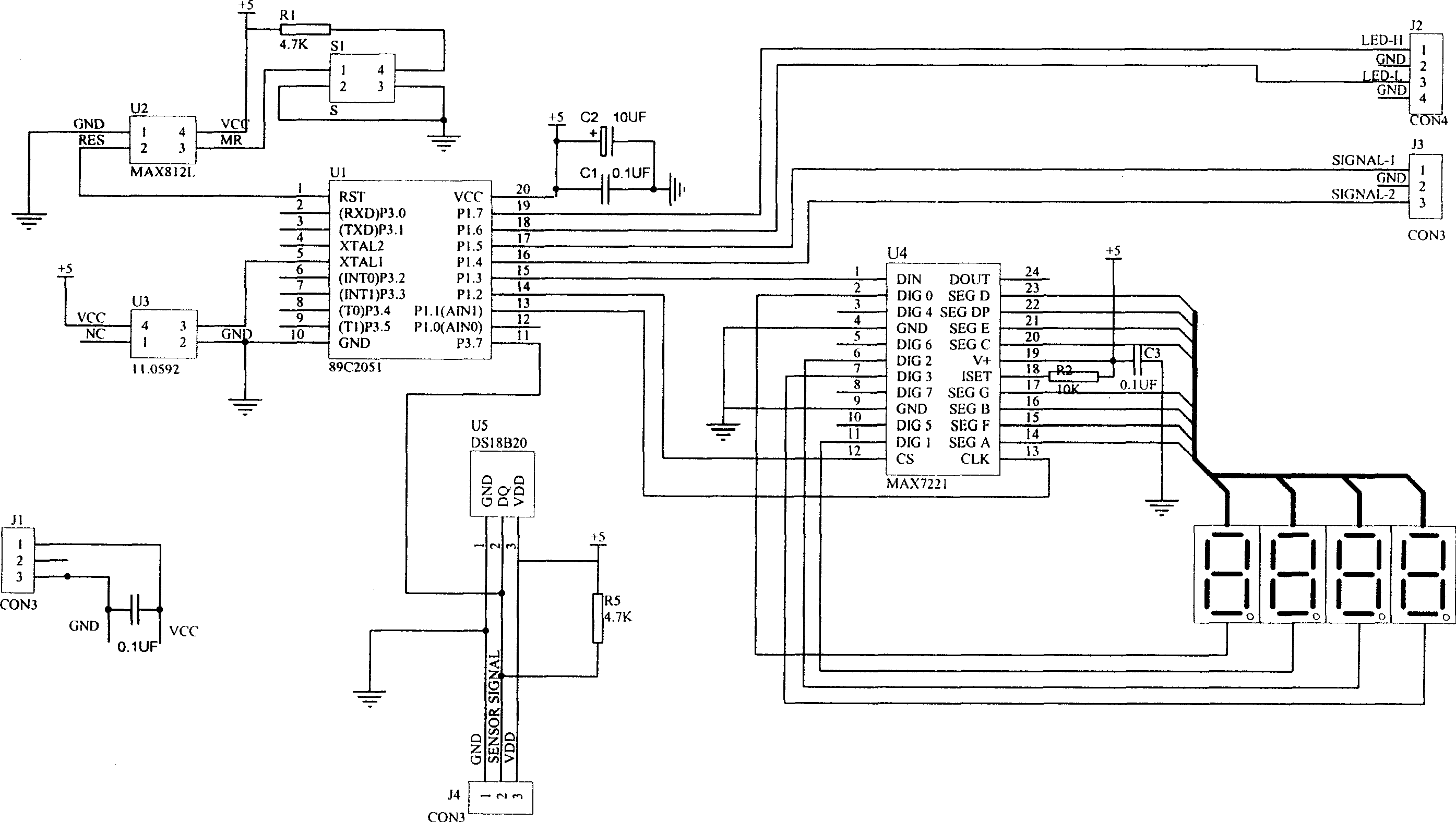

[0028] The control circuit board 3 includes a single chip microcomputer 11 , a filter capacitor 12 , a reset circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com