Method for manufacturing nanometer metal powder

A technology of nano-metal powder and manufacturing method, which is applied in the field of nano-material manufacturing, which can solve the problems of uneven size, low height, and difficulty in controlling the dispersion of nano-metal powder, and achieve the effect of uniform size controllable and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] Please refer to Figure 1 to Figure 6 , is a flow chart of the manufacturing method of the nano metal powder provided by the present invention. It includes the following steps:

[0019] (a) provide a substrate 10, which has a substrate surface 100, the substrate surface 100 can be processed by chemical polishing to obtain a flat surface (such as figure 1 shown), the substrate material is selected from Si, SiO 2 , GaAs, GaP or InP, etc., the present invention uses a silicon substrate.

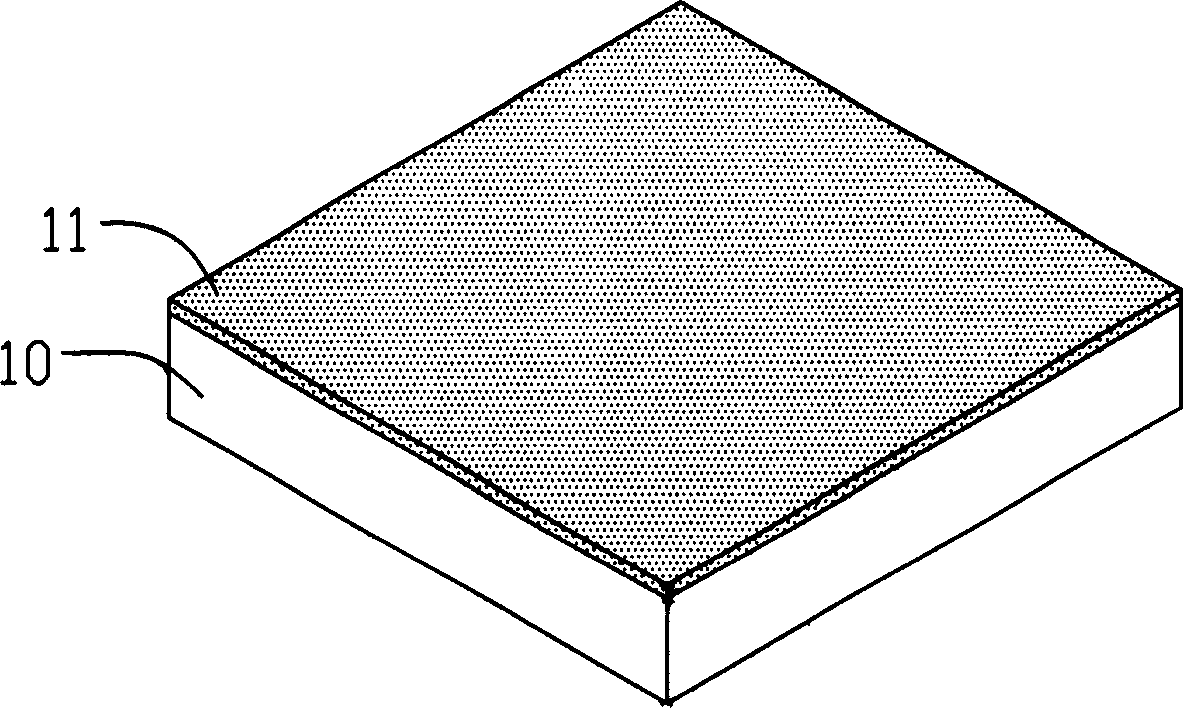

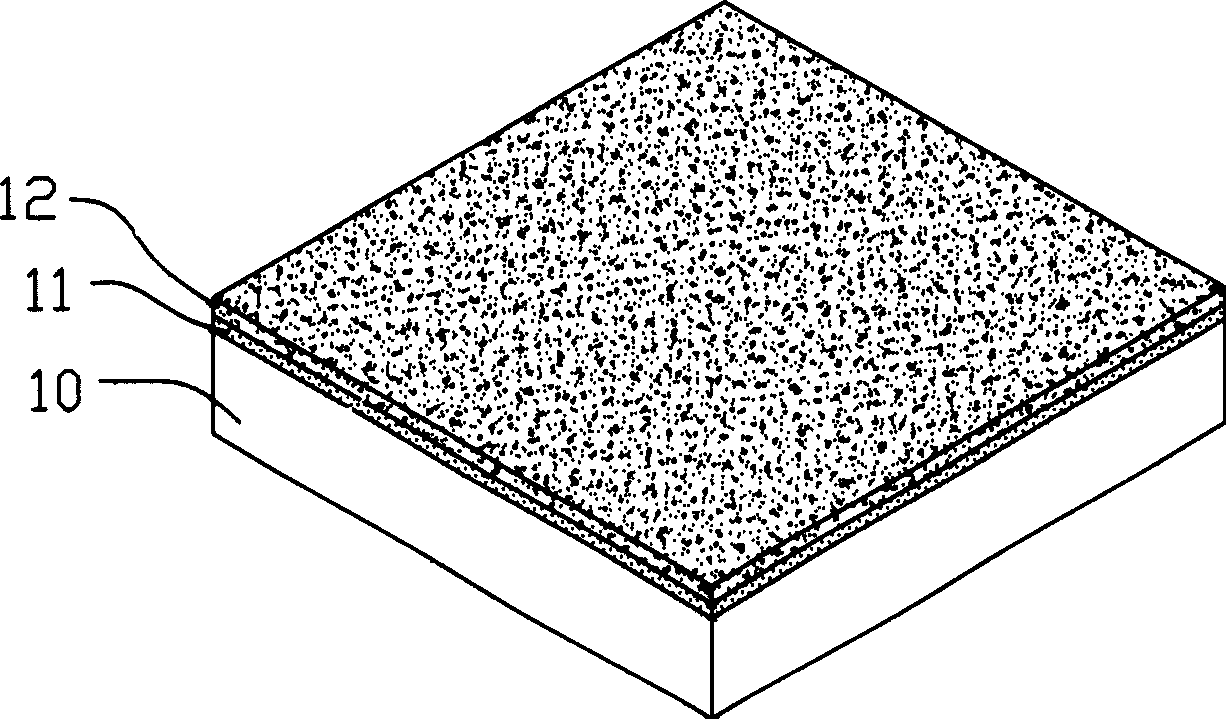

[0020] (b) on the surface 100 of the substrate 10 (such as figure 1 Shown) deposit a layer of metal thin film 11 (such as figure 2 As shown), the obtained metal thin film 11 has a thickness of nanometer scale, which can be 1 nanometer to 100 nanometers. The metal is selected from copper, aluminum, nickel, etc., and copper is used in the present invention. Wherei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com