Process for preparing noncrystalline nickel-phosphor-core - shell, hollow shell structure material

A technology of amorphous nickel and structural materials, which is applied in the field of preparation of new core-shell and hollow-shell materials, can solve problems such as reports that have not been disclosed, and achieve the effects of simple and easy-to-control preparation methods, clear structures, and good structural effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

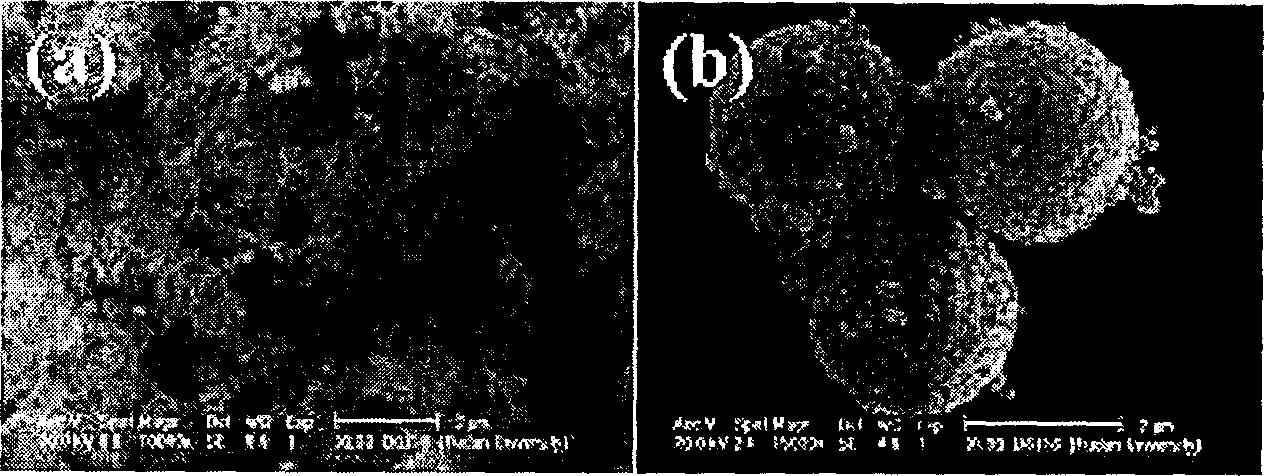

[0026] Example 1: Polystyrene beads activated with Pd ions

[0027] Polystyrene pellets in 0.01M SnCl 2 Immerse in the solution for 2 minutes, centrifuge and put it into 0.001M PdCl 2 Immerse in the solution for 2 minutes, then centrifuge and wash with water three times to completely remove free metal Pd particles.

[0028] The selected composition is 45g / L NiCl 2 ·6H 2 O, 20g / L NaH 2 PO 2 ·H 2 O, 45g / L Na 3 C 6 h 5 o 7 2H 2 O, 50g / LNH 4 Cl electroless plating solution, pH value about 9, react at 95°C for 10 minutes, centrifuge and wash the product three times with water and three times with ethanol. Its scanning electron microscope image is shown in figure 1 .

Embodiment 2

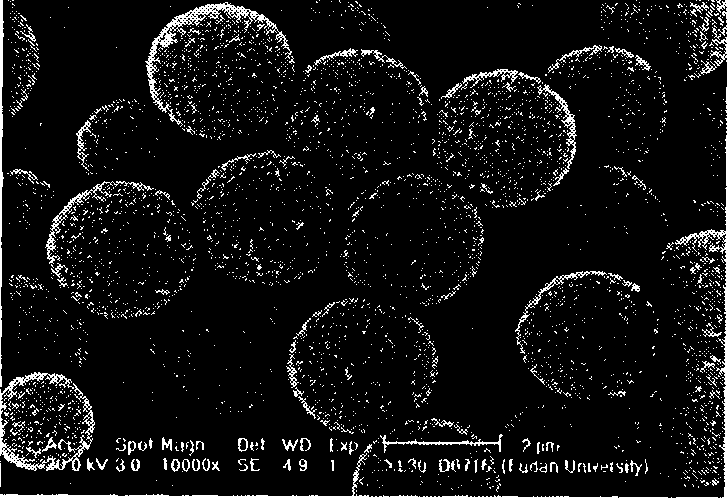

[0029] Example 2: Preparation of Ni-P / PS core-shell structure material at low temperature by activation of Pt

[0030] Polystyrene pellets in 0.1M SnCl 2 Immerse in the solution for 2 minutes, centrifuge and put it into 0.01M PtCl 2 Immerse in the solution for 2 minutes, then centrifuge and wash with water three times to completely remove free metal Pt particles.

[0031] The selected composition is 30g / L NiSO 4 ·7H 2 O, 30g / L NaH 2 PO 2 ·H 2 O, 60g / L Na 4 P 2 o 7 10H 2 The electroless plating solution of O, the pH value is about 10, reacted for 3 minutes at 25°C, and the product was centrifuged and washed three times with water and three times with ethanol. Its scanning electron microscope image is shown in figure 2 .

Embodiment 3

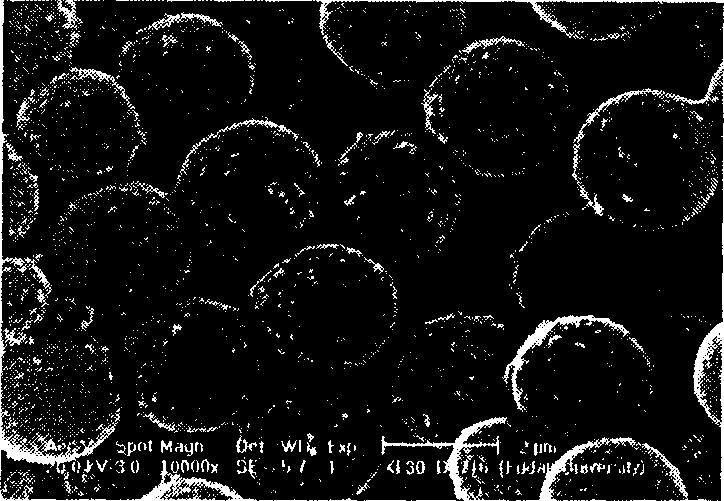

[0032] Embodiment 3: Preparation of Ni-P / PS core-shell structure material by Ag activation

[0033] Polystyrene pellets in 0.002M SnCl 2 Immerse in the solution for 2 minutes, centrifuge and put it into 0.0005MAgNO 3 Immerse in the solution for 2 minutes, then centrifuge and wash with water three times to completely remove free metal Ag particles.

[0034] The selected composition is 30g / LNiCl 2 ·6H 2 O, 10g / L NaH 2 PO 2 ·H 2 O, 100g / L Na 3 C 6 h 5 o 7 2H 2 O, 50g / LNH 4 Cl electroless plating solution, pH value is about 8, reacted at 60°C for 200 minutes, the product was centrifuged and washed three times with water and three times with ethanol. Its scanning electron microscope image is shown in image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com