Antibacterial packing plastic bottle

A packaging, antibacterial plastic technology, applied in the direction of the bottle, etc., to achieve the effect of long antibacterial effect, ensure compatibility, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

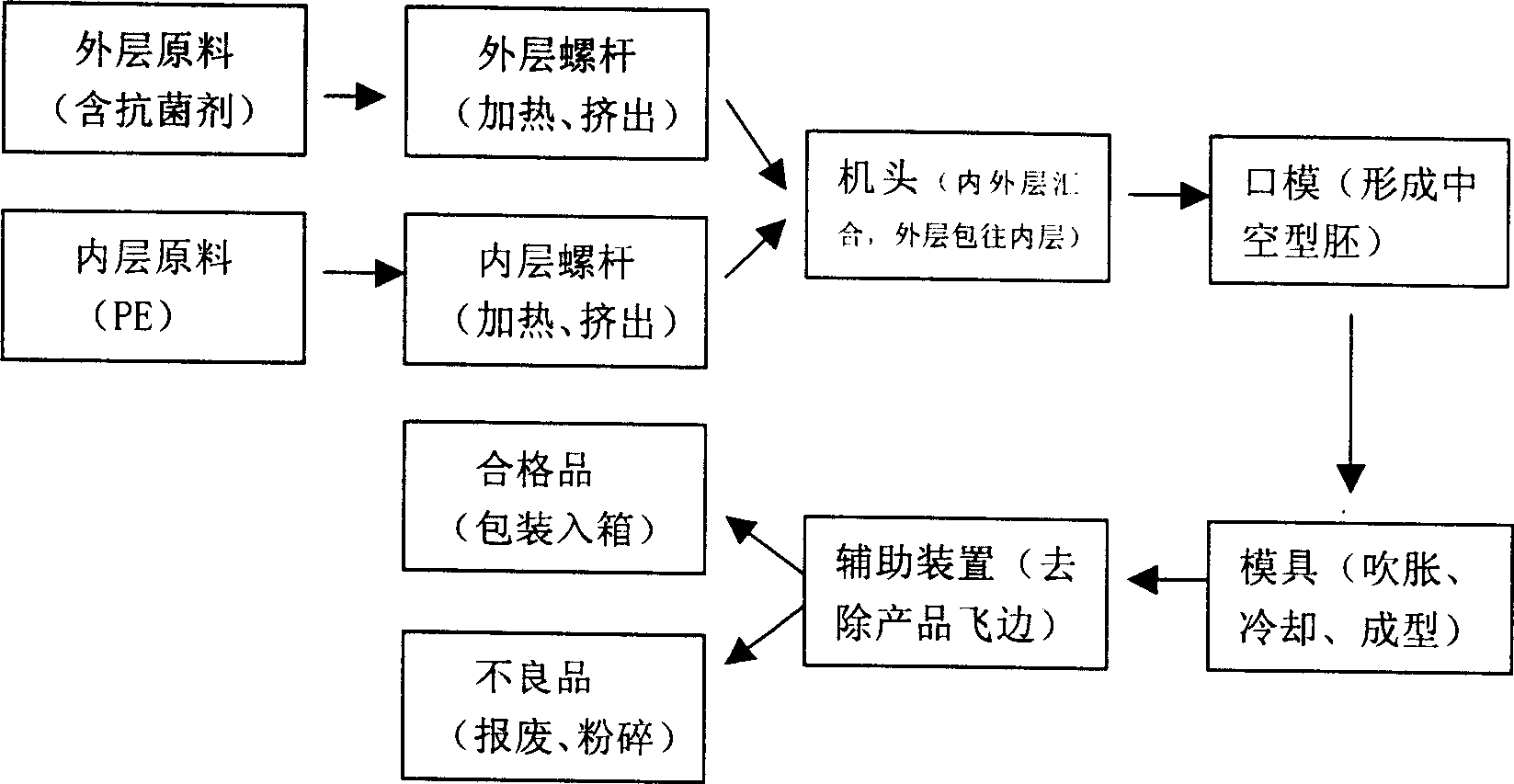

[0012] From the accompanying drawings, we can see that the process flow of the present invention is equipped with high-density polyethylene and antibacterial agent-containing raw materials according to the inner and outer layers respectively, adopts twin-screw extruder to heat and extrude, and is made into a preform by a die, and then The preforms are inflated, cooled, and formed in the mold, and the qualified products are packed into boxes after the auxiliary device removes the product flash, and the defective products are scrapped and crushed.

[0013] In the present invention, the preform is made of the inner layer raw material and the outer layer raw material respectively, and the inner layer raw material high-density polyethylene is heated and extruded by the inner layer screw extruder; silver ion antibacterial agent is added to the outer layer raw material, and the particle diameter of the antibacterial agent is 3um ~5um, the antibacterial agent uses soluble phosphate gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com