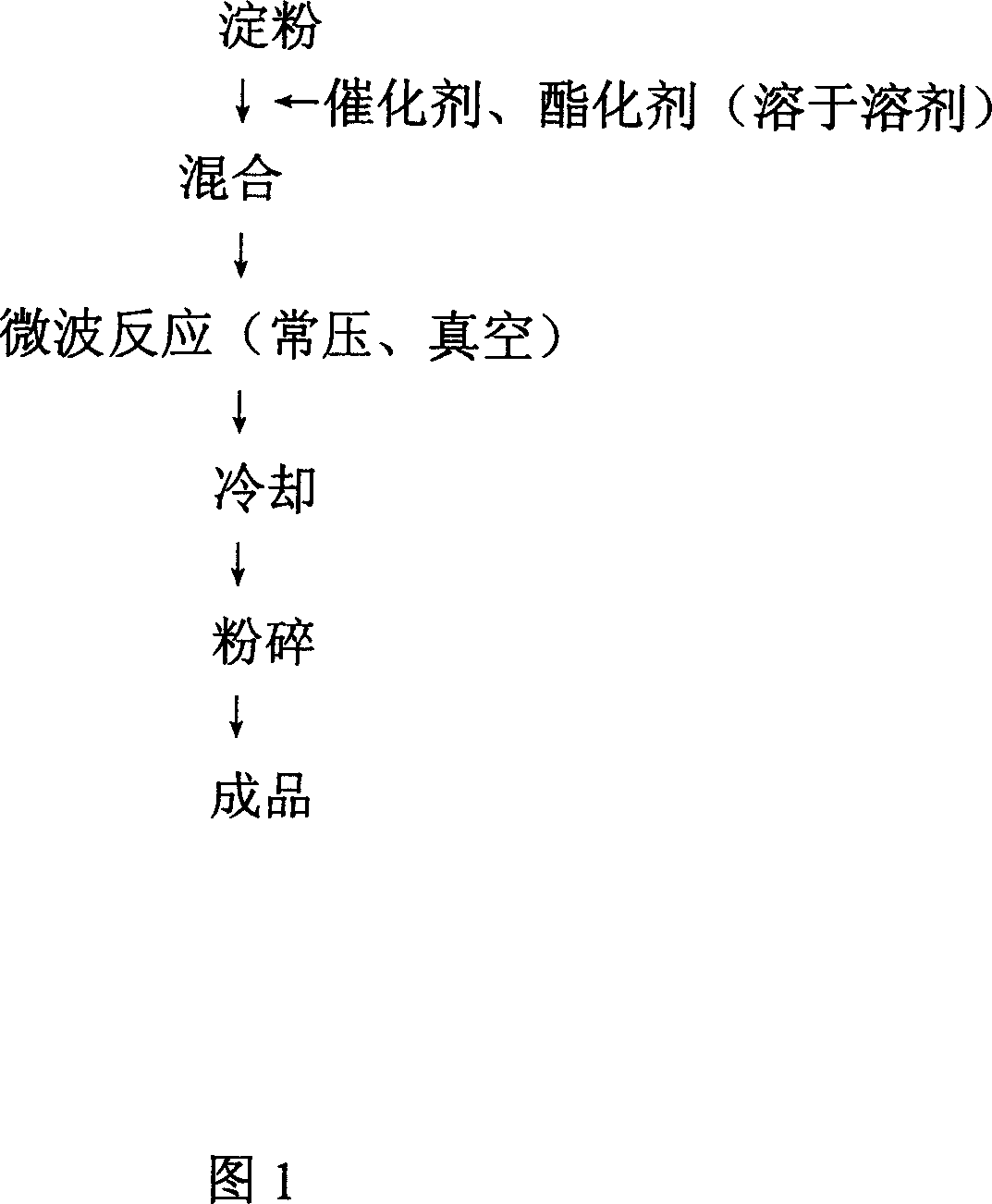

Process for preparing modified composite denatured starch by microwave acidiolysis and esterification

A technology of compound modified starch and esterification modification, which is applied in the field of modified starch to achieve the effects of improving reaction efficiency, reducing costs and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Weigh 2g of stearic acid, dissolve it in 80ml of 70°C absolute ethanol, add 0.05g of hydrochloric acid, keep the temperature at 70°C without adding water, then slowly add 100g of starch (dry basis) and keep stirring to obtain a uniform mixture. Put the mixture into a container and place it in a 700W microwave oven for reaction, heat intermittently for 30s, stir rapidly, and irradiate with microwaves for 3 minutes, cool and pulverize to obtain the finished starch stearate. The microwave oven is the NJL07-3 experimental microwave oven produced by Nanjing Jiequan Microwave Equipment Co., Ltd., the same below.

[0028] Prepare stearyl starch ester with stearic acid and starch reaction, adopt common pressure dry method, microwave normal pressure dry method and microwave vacuum dry method three different methods to prepare the product performance of stearic acid starch ester as shown in table 1 . The reaction efficiency is the ratio of the actual degree of substitution to th...

Embodiment 2

[0034] Weigh 4g of lauric acid, dissolve it in 120ml of 70°C absolute ethanol, add 0.2g of acetic acid, and at the same time add 40ml of water to maintain the temperature at 70°C, then slowly add it to 100g of starch (dry basis), and keep stirring to obtain a homogeneous mixture , Put the mixture into a container and place it in a 1200W microwave oven to evacuate it for reaction. The microwave radiation time is 10 minutes. After cooling, it is pulverized to obtain the finished starch laurate ester.

Embodiment 3

[0036] Linoleic acid is used as esterifying agent, and all the other prescriptions and operating conditions are the same as embodiment 1 or embodiment 2, and make finished product linoleic acid starch ester.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com