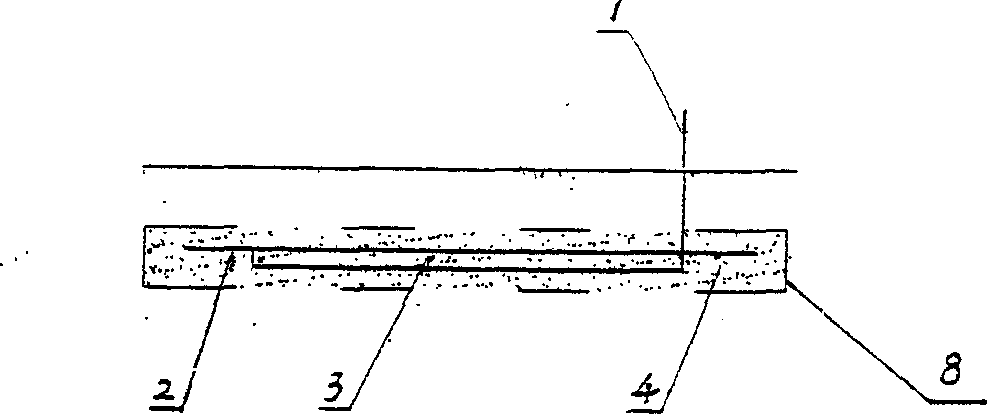

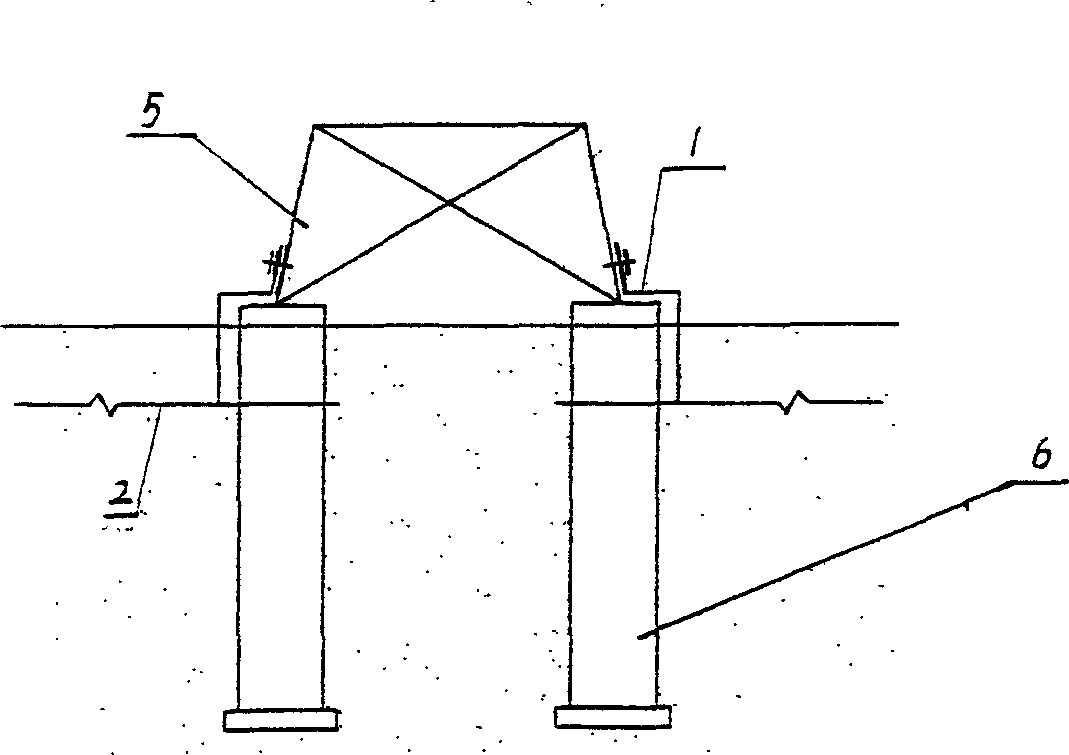

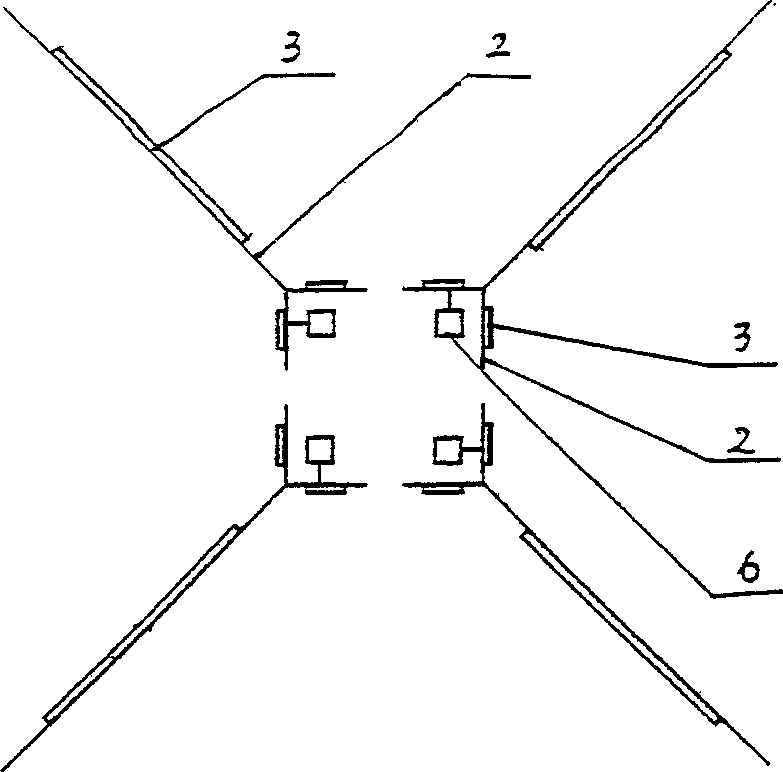

Electrochemical earthing body

A grounding body and electrochemical technology, which is applied in the field of electrochemical grounding body, can solve the problems that the resistance reduction effect cannot reach the expected target value, sacrificial anodes should not be used, and the performance-price ratio is unreasonable, etc., and the resistance reduction effect is obvious, Significant resistance reduction effect, high cost performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] The components and weight percentages of the drag reducing agent are:

[0105] SiO 2 35.5%; CaSO 4 16.1%; MgSO 4 27.5%; Al 2 o 3 7.9%; Mg(OH) 2 5.7%;Na 2 SO 4 3.1%; MgO 1.65%; CaO 1.35%; Fe 2 o 3 0.75%;K 2 O 0.15%; Na 2 O 0.15%; TiO 2 0.15%;

[0106] After uniformly mixing the powders of each component, the mixture is obtained, which is used as a drag reducing agent for direct construction, and the components interact with each other through underground moisture to achieve the purpose of reducing drag; or, add water according to the mass ratio mixture: water = 1:3 After stirring evenly, it can be used as a drag reducing agent before construction.

Embodiment 2

[0108] The composition and weight percentage of drag reducing agent are: SiO 2 32.0%; CaSO 4 25.2%; MgSO 4 20.0%; Al 2 o 3 7.1%; Mg(OH) 2 8.0%;Na 2 SO 4 4.2%; MgO 1.5%; CaO 1.0%; Fe 2 o 3 0.7%;K 2 O 0.1%; Na 2 O 0.1%; TiO 2 0.1%.

[0109] After uniformly mixing the powders of each component, a mixture is obtained, which is used as a drag reducing agent for direct construction, and the components interact with each other through underground moisture to achieve the purpose of reducing drag; or, add water according to the mass ratio mixture: water = 1: 2.5 After stirring evenly, it can be used as a drag reducing agent before construction.

Embodiment 3

[0111] The composition and weight percentage of drag reducing agent are: SiO 2 39.0%; CaSO 4 7.0%; MgSO 4 35.0%; Al 2 o 3 8.7%; Mg(OH) 2 3.4%; Na 2 SO 4 2.0%; MgO 1.8%; CaO 1.7%; Fe 2 o 3 0.8%;K 2 O 0.2%; Na 2 O 0.2%; TiO 2 0.2%.

[0112] After the powders of each component are uniformly mixed, the mixture is obtained, which is used as a drag reducing agent for direct construction, and the components are interacted with each other through underground moisture to achieve the purpose of reducing drag; or, the mass ratio of the mixture: water = 1: 4.5 After adding water and stirring evenly, it can be used as a drag reducing agent before construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com