Semiconductor device and manufacturing method thereof

A semiconductor and device technology, applied in the field of semiconductor devices and their manufacturing, can solve problems such as inability to provide transistor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings.

[0030] The present invention is described with reference to the accompanying drawings so that those skilled in the art can practice the present invention. It will be apparent to those skilled in the art that the described embodiments may be modified in various ways without departing from the spirit of the invention as disclosed in the claims.

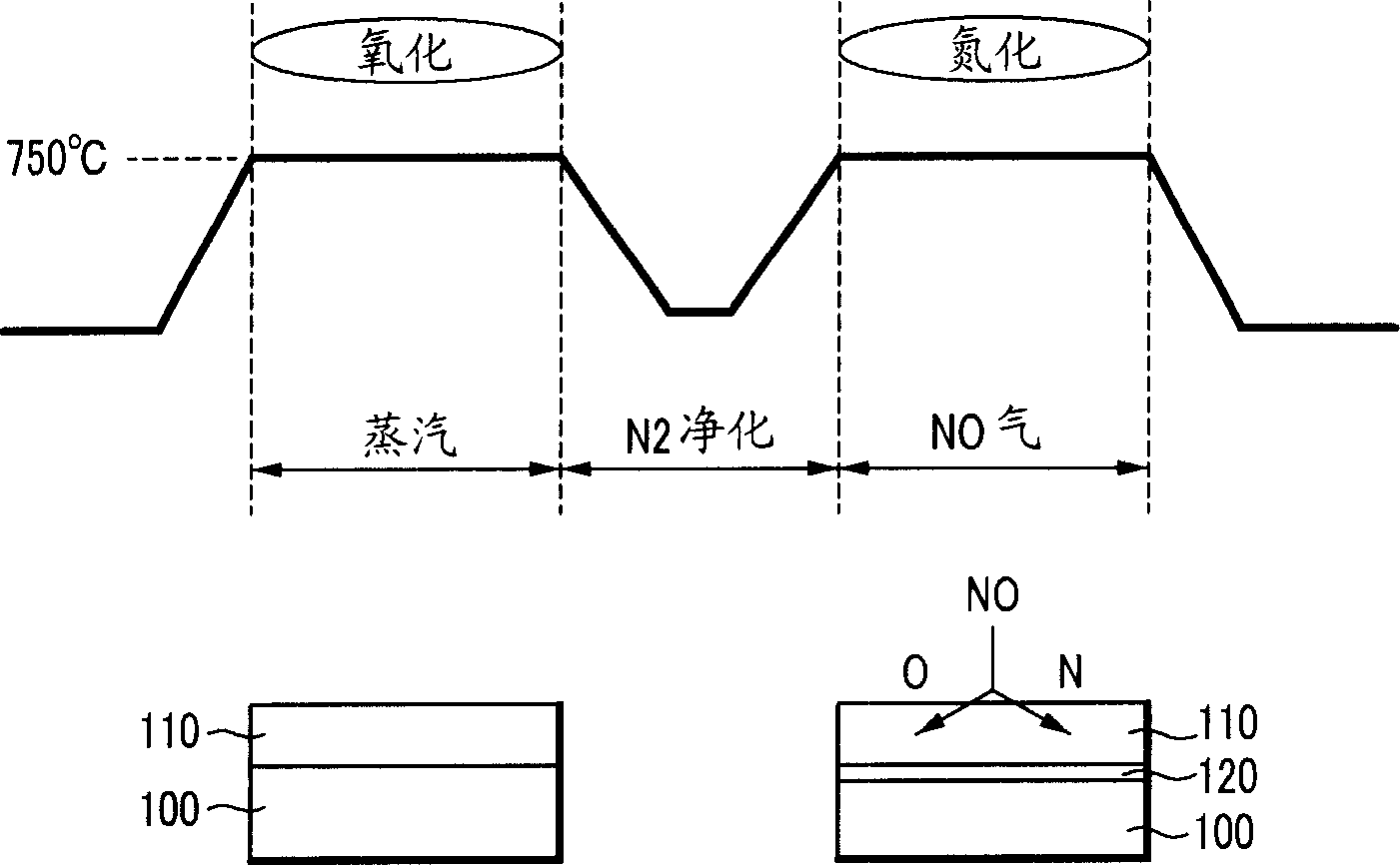

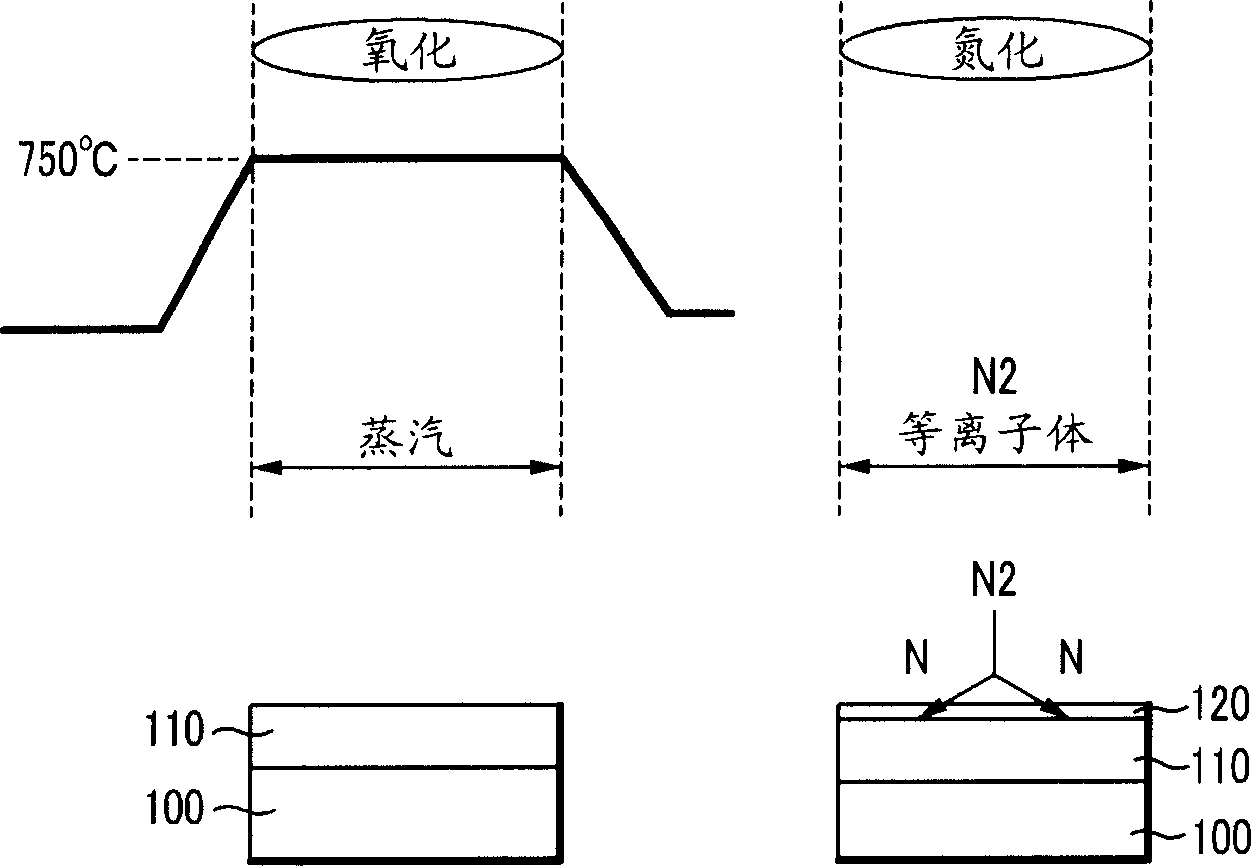

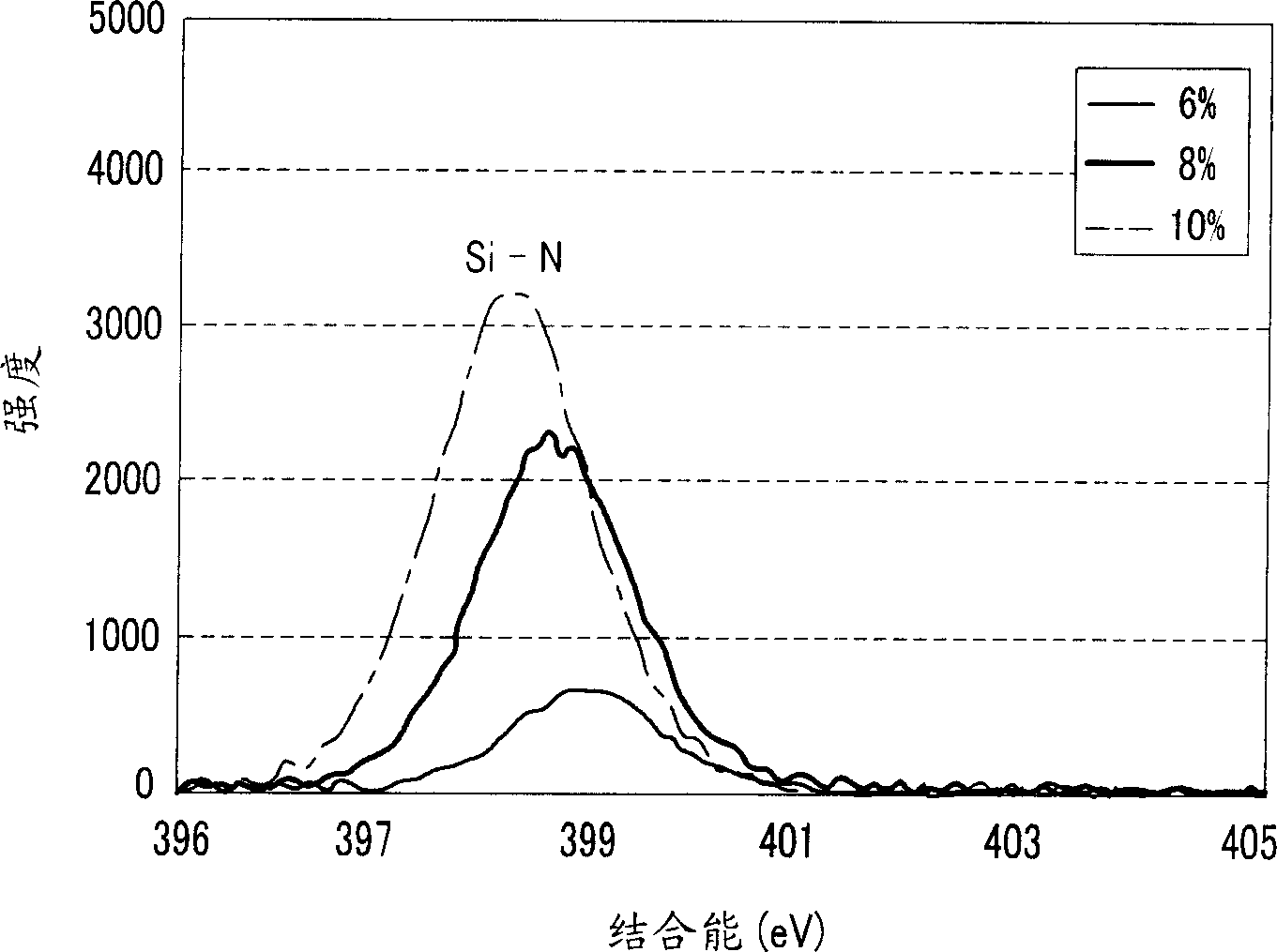

[0031] Figure 1A shows a method for thermally forming a nitride layer, Figure 1B A method for forming a nitride layer using plasma is shown. The nitriding method can be classified into a thermal nitriding method and a plasma nitriding method.

[0032] Also, depending on how water or steam is generated (H 2 O), the gate oxide forming method can be classified into a torch method and a water vapor generator (WVG for short) method. The WVG method can form a thinner oxide layer. In the flame method, water or ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com