Wafer measuring system

A technology for measuring systems and wafers, applied in the fields of high-frequency components, circuit components and system functions, can solve the problems of occupying space, difficult to provide the shock-proof function of the probe machine at the same time, signal strength loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The preferred embodiments of the present invention are described in detail below in conjunction with the accompanying drawings, but these descriptions are only used to illustrate the present invention, rather than to limit the scope of rights of the present invention.

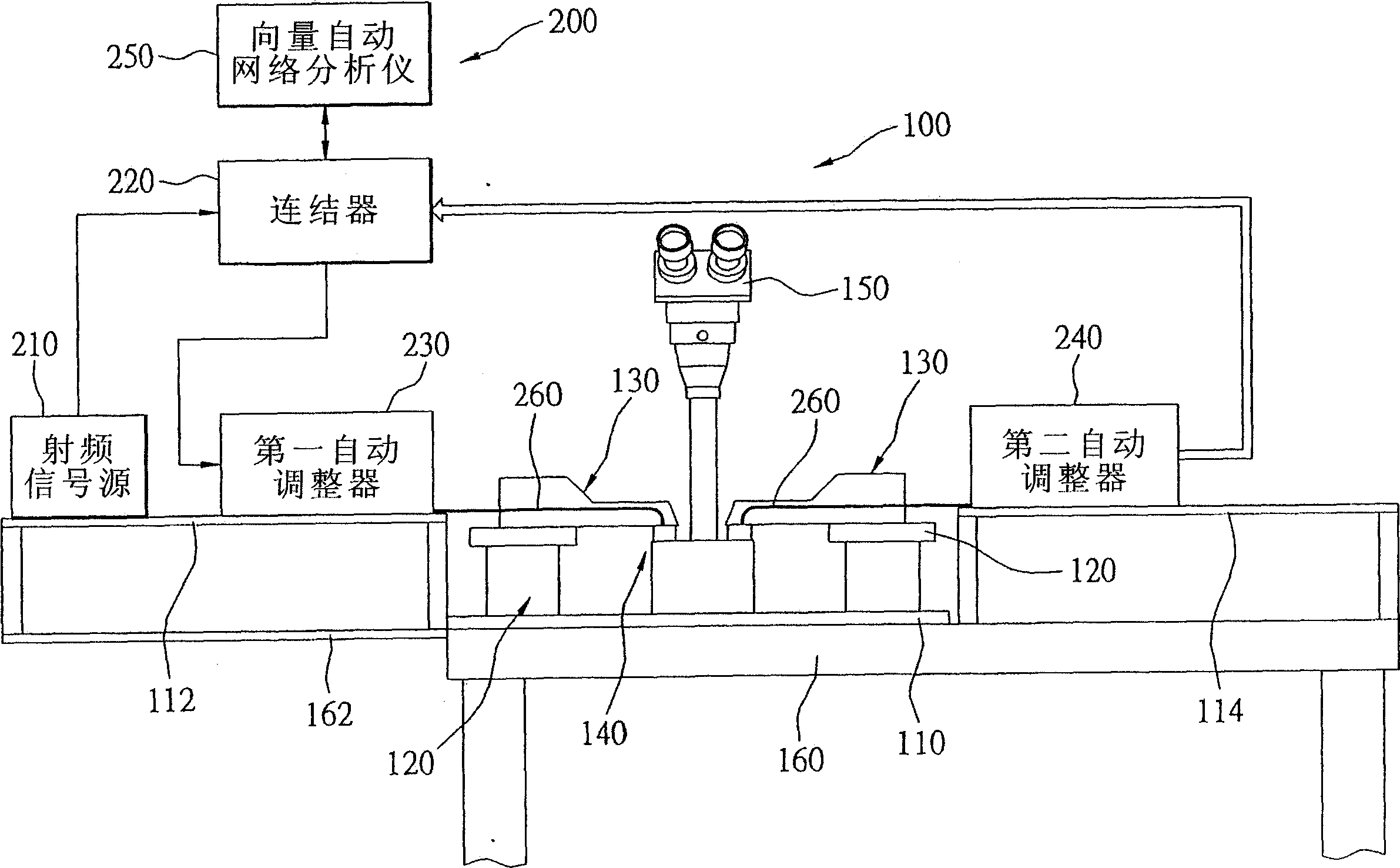

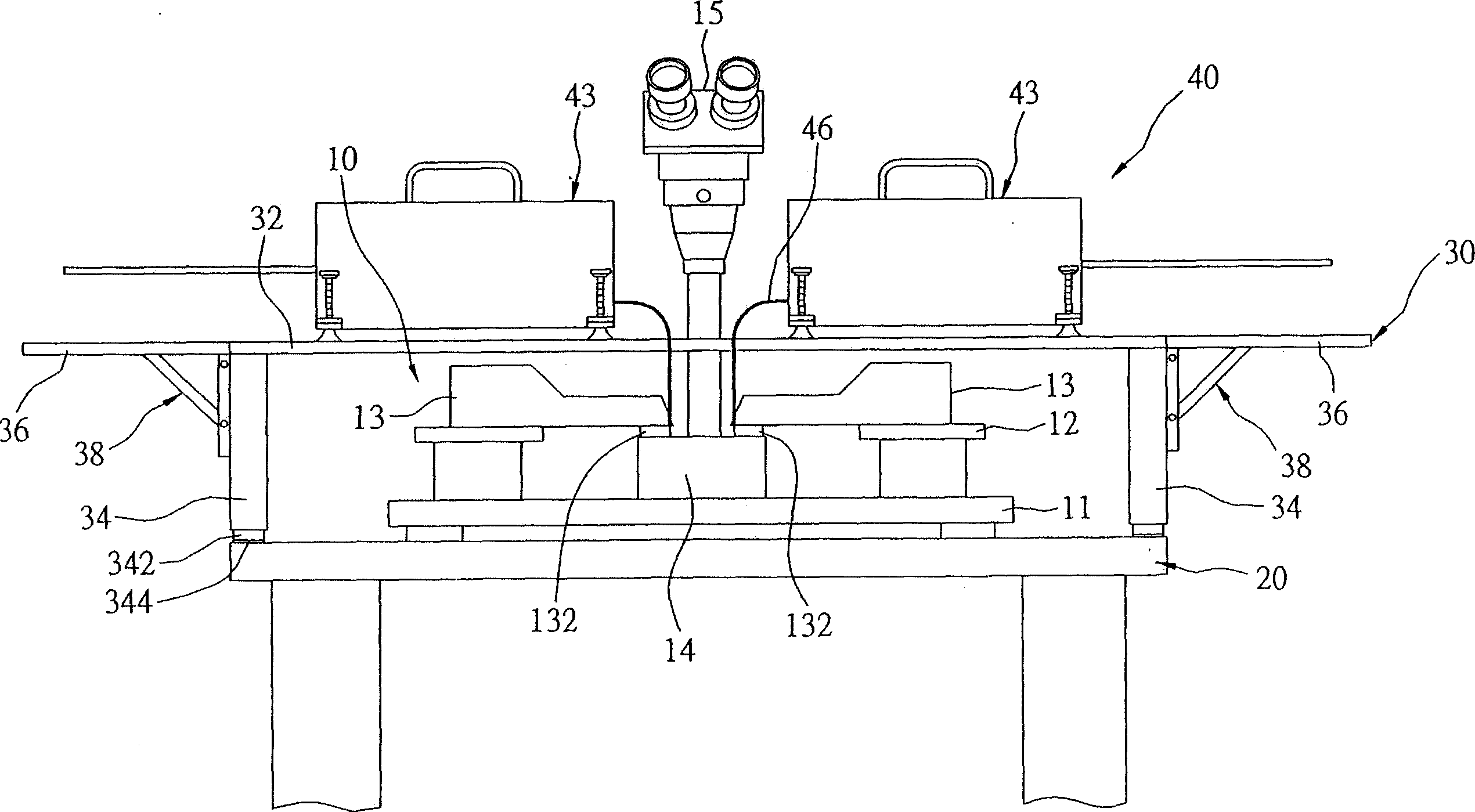

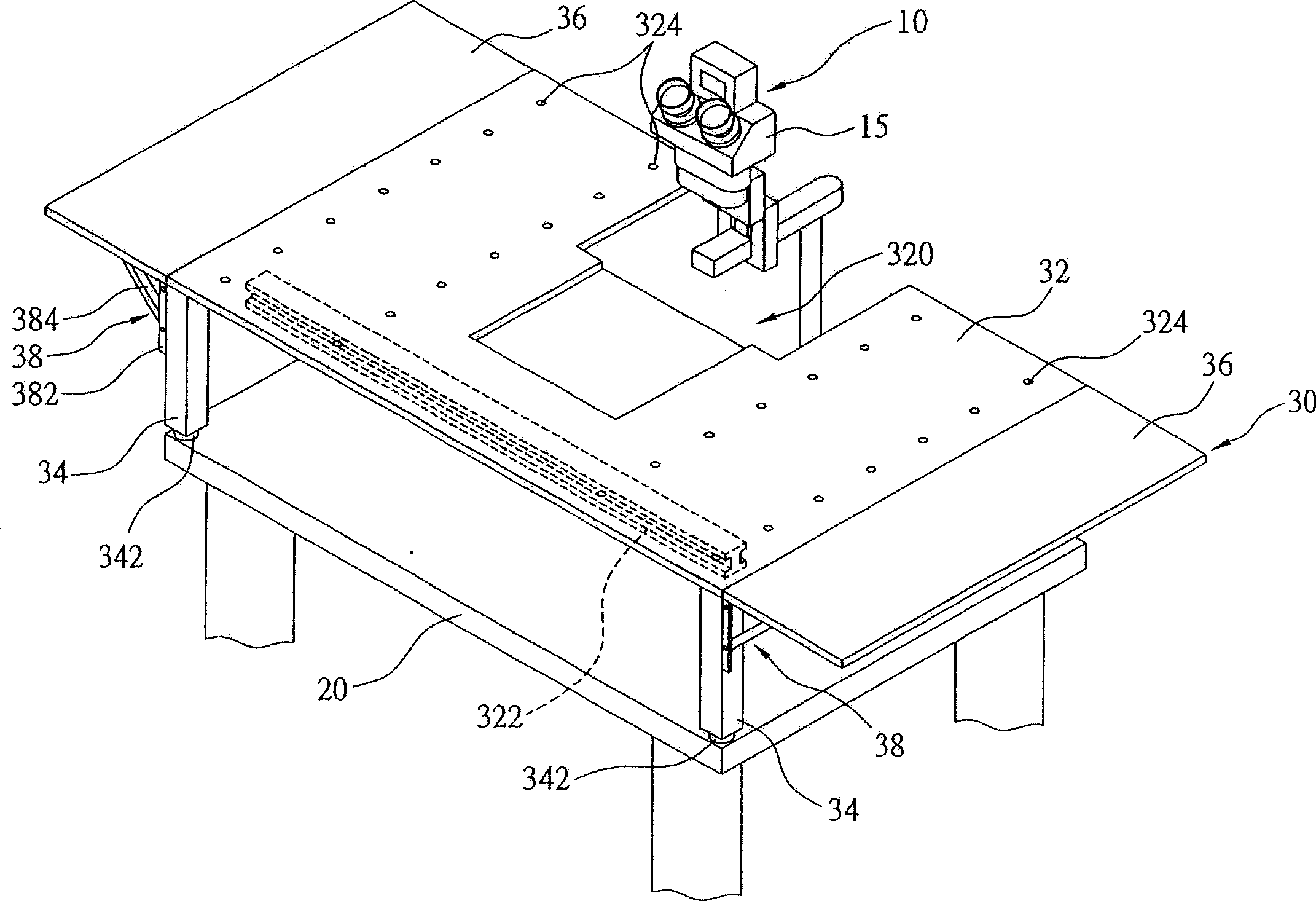

[0043] see figure 2 and image 3 , are respectively the front view of the wafer measurement system of the present invention and the perspective view of the carrying device of the present invention. The wafer measurement system provided by the present invention includes a probe machine 10 , a shockproof table 20 , a carrying device 30 , and a high-frequency measurement device 40 .

[0044] The probe machine 10 includes a base 11 , a probe platform 12 , a pair of probe holders 13 , a wafer holder 14 , and a microscopic observation device 15 . The probe platform 12 is placed on the base 11; the pair of probe supports 13 are respectively placed on both sides of the probe platform 12; the wafer holder 14 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com