Ribbon type sound film of plane loudspeaker and its manufacturing method

A planar loudspeaker and manufacturing method technology, applied in the direction of diaphragm structure, sensor, electrical components, etc., can solve the problems of low sound pressure, heavy weight, etc., and achieve the effects of good sensitivity, light weight, and simple manufacturing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

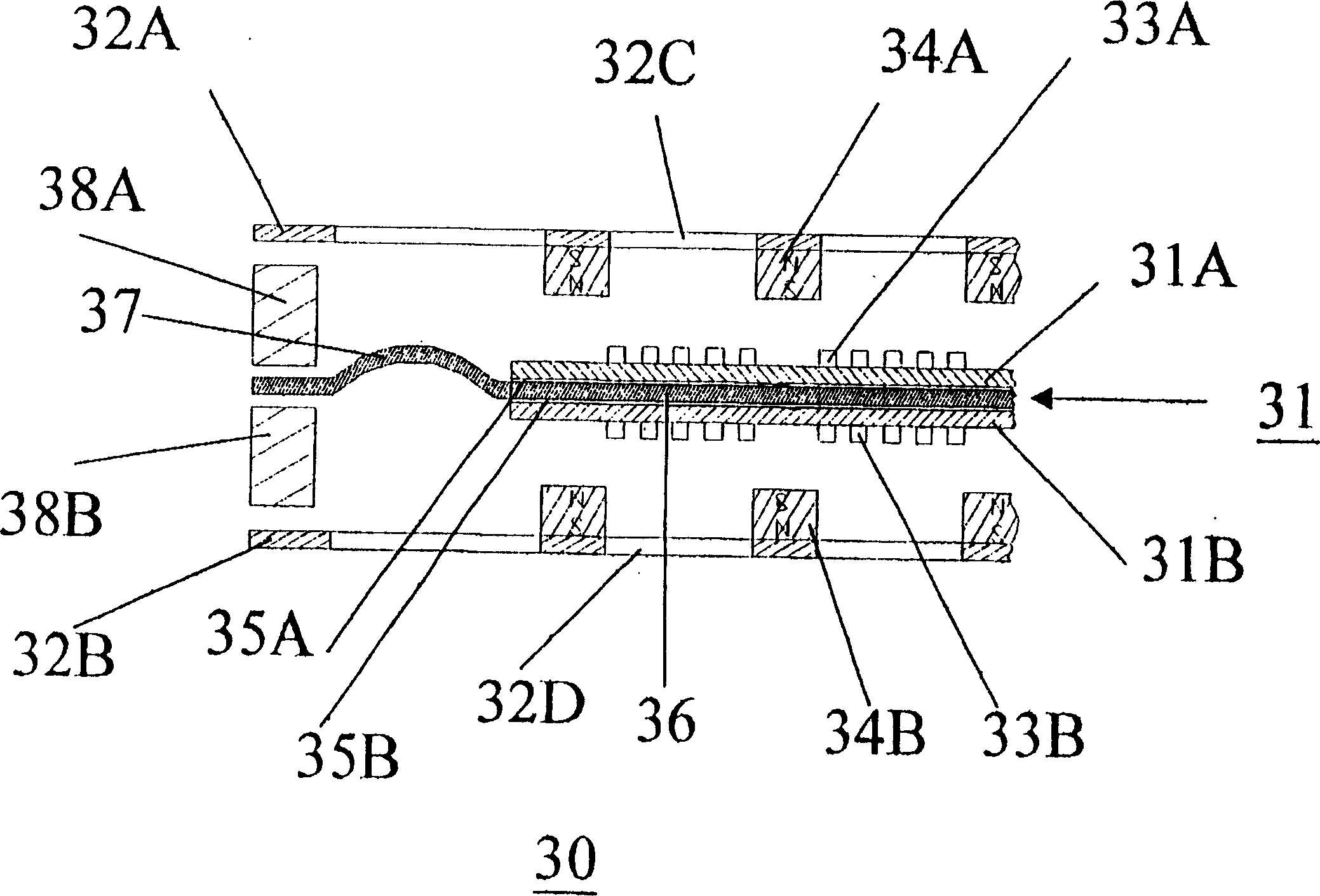

[0022] Please refer to image 3 , which is a cross-sectional view of an embodiment of the ribbon type planar speaker of the present invention. The composite sound membrane 31 of the loudspeaker includes an upper ribbon-shaped sound membrane, a planar reinforcing structure 36, and a lower ribbon-shaped sound membrane. The upper ribbon-shaped sound film is composed of an upper insulating layer 31A and a metal electrode circuit 33A on the upper side of the upper insulating layer. , the lower ribbon-shaped sound film is composed of the lower insulating layer 31B and the metal electrode circuit 33B on the lower side of the lower insulating layer. The planar reinforcing structure 36 further has a hanging edge structure 37 .

[0023] Wherein, the upper ribbon-shaped sound film and the lower ribbon-shaped sound film are two-layer composite metal films of metal foil / polymer insulation layers 31A, 31B. It first uses a 23 micron thick aluminum foil layer and a 10 micron thick polyimid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com