Polyimide polymer, preparation method and application

A technology of polyimide and polymer, which is applied in the application of the above-mentioned gas separation membrane and the preparation field of the above-mentioned polymer, can solve the problems such as difficult composite membrane coating, difficult to find good solvent, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

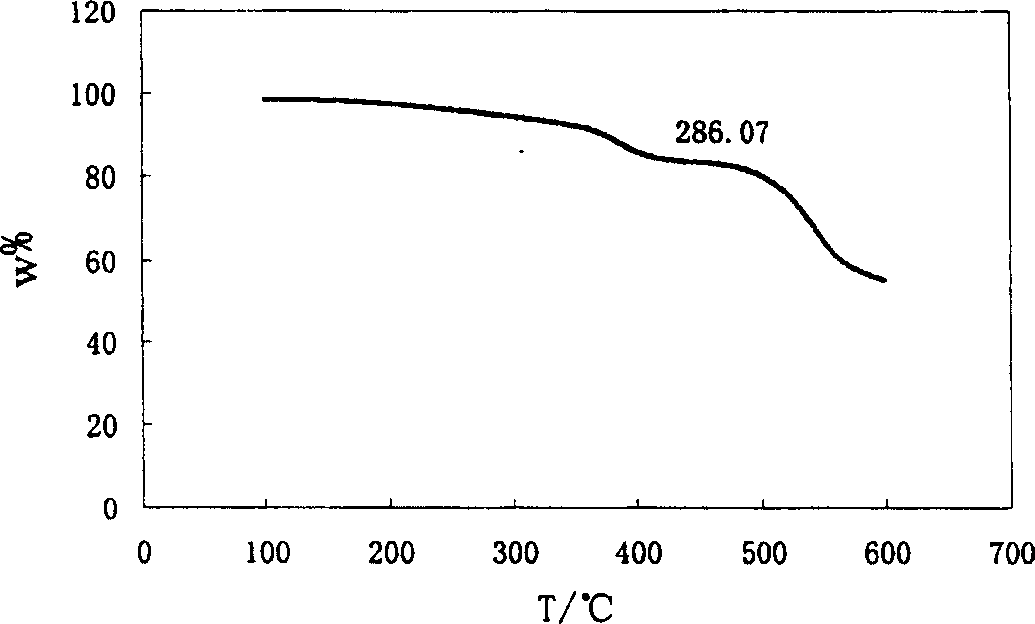

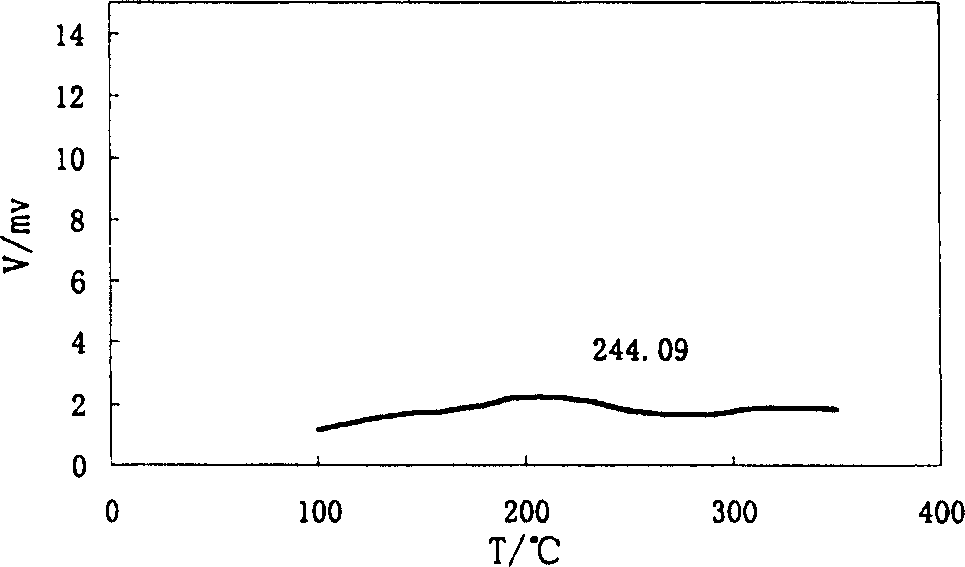

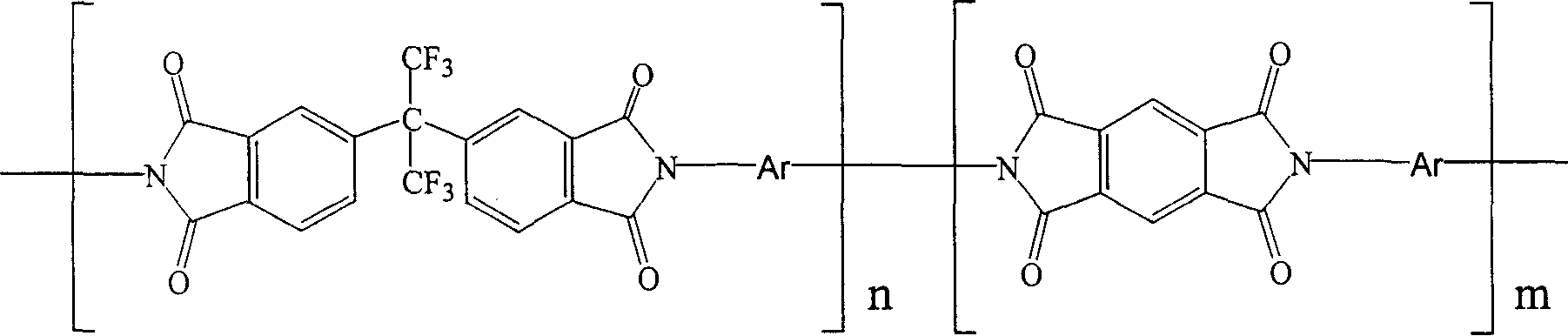

[0032] Add 4.724g 3,5-diamino-2,4,6-trimethylbenzenesulfonate lithium salt (MLi), 41.226g dimethyl sulfoxide and 9.018g 4 in a stirred 100ml three-neck round bottom flask , 4'-hexafluoroisopropylidene-phthalic anhydride (6FDA) powder. Stir the reaction mixture at 20-30°C under nitrogen protection for 3 hours to form a very viscous solution, then add 10g of acetic anhydride and 2g of triethylamine for imidization, react for 4 hours, settle in acetone, and filter , washed three times with acetone, dried at room temperature for 3 hours, and then dried at 170° C. for 24 hours to obtain 6FDA-MLi polyimide. figure 1 is the TGA curve of polymer 6FDA-MLi. It can be seen from the figure that the glass transition temperature of 6FDA-MLi polyimide is 244.09°C; figure 2 is the DSC curve of polymer 6FDA-MLi. It can be seen from the figure that the 5% thermal weight loss temperature of 6FDA-MLi polyimide is 286.07°C.

Embodiment 2

[0034] Add 4.724g 3,5-diamino-2,4,6-trimethylbenzenesulfonate lithium salt (MLi), 34.341g dimethylsulfoxide and 4.509g 4 to a stirred 100ml three-neck round bottom flask , 4'-hexafluoroisopropylidene-phthalic anhydride (6FDA) and 2.214 g of pyromellitic dianhydride (PMDA) powder. Stir the reaction mixture at 20-30°C for 3 hours to form a very viscous solution, then add 10g of acetic anhydride and 2g of triethylamine for imidization, react for 4 hours, settle in acetone, filter and wash with acetone three times , Dry at room temperature for 3 hours and then dry at 170° C. for 24 hours to obtain light yellow 6FDA / PMDA (50 / 50)-MLi type polyimide powder.

Embodiment 3

[0036]Add 4.724g 3,5-diamino-2,4,6-trimethylbenzenesulfonate lithium salt (MLi), 27.457g dimethyl sulfoxide and 4.428g Pyellitic dianhydride (PMDA) powder. Stir the reaction mixture at 20-30°C under nitrogen protection for 3 hours to form a very viscous solution, then add 10g of acetic anhydride and 2g of triethylamine for imidization, react for 4 hours, settle in acetone, and filter , washed three times with acetone, dried at room temperature for 3 hours, and then dried at 170° C. for 24 hours to obtain 6FDA-MLi polyimide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com