Granulation spray nozzle differential rotating granulation

A technology of differential rotation and nozzle, which is applied in the direction of spraying device with movable outlet, spraying device, liquid is divided into beads and granulated, and can solve the problem of nozzle hole blockage of granulation nozzle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

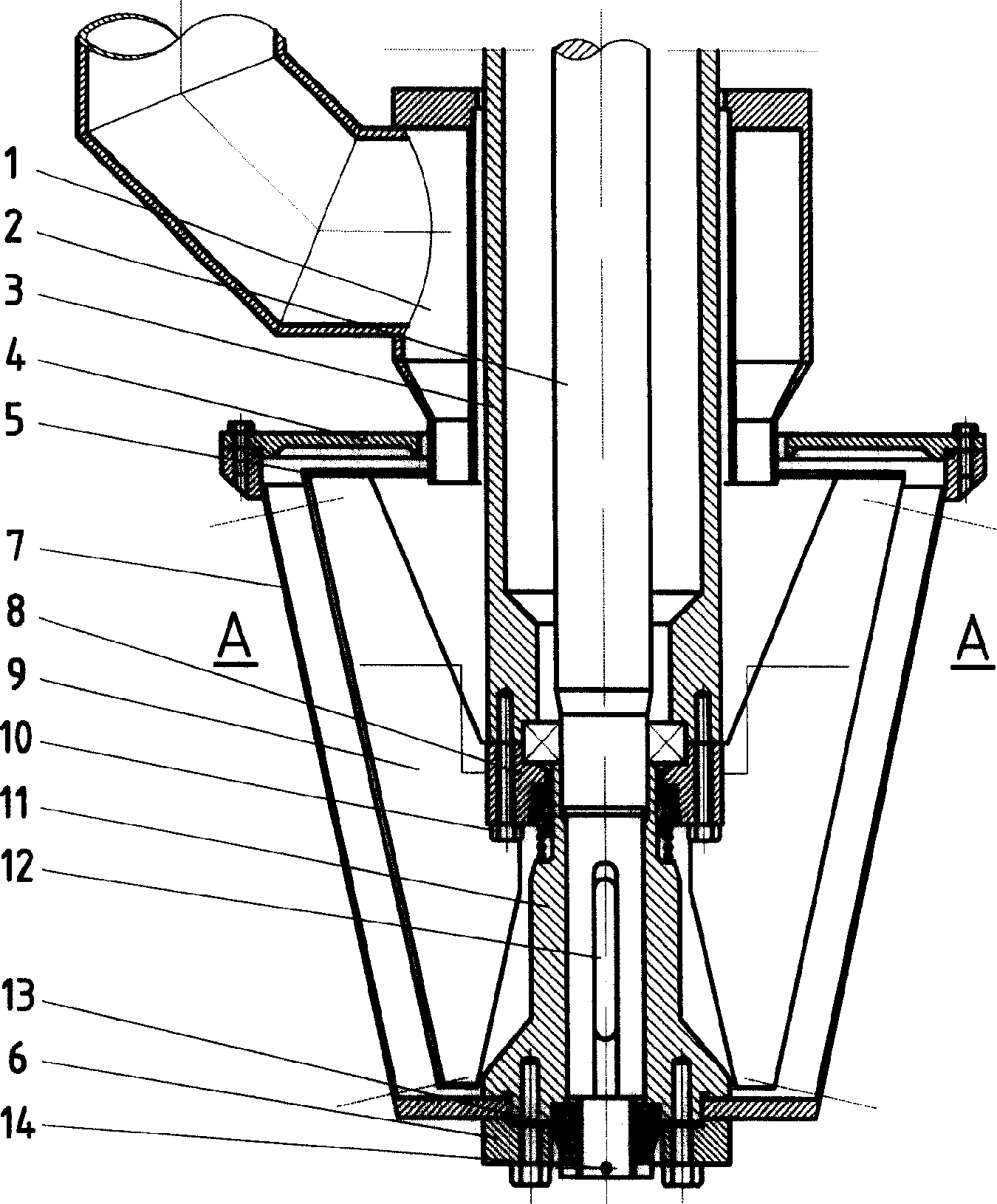

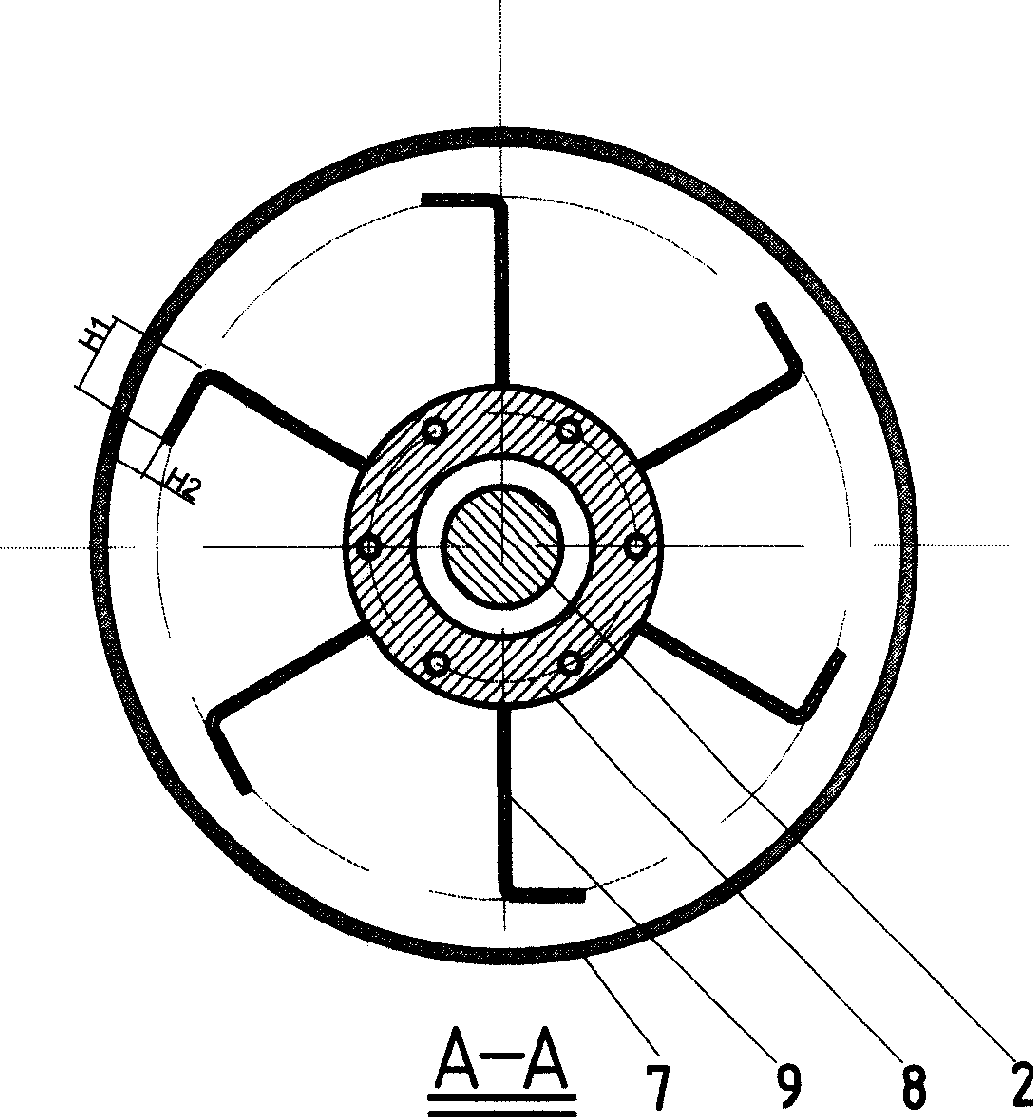

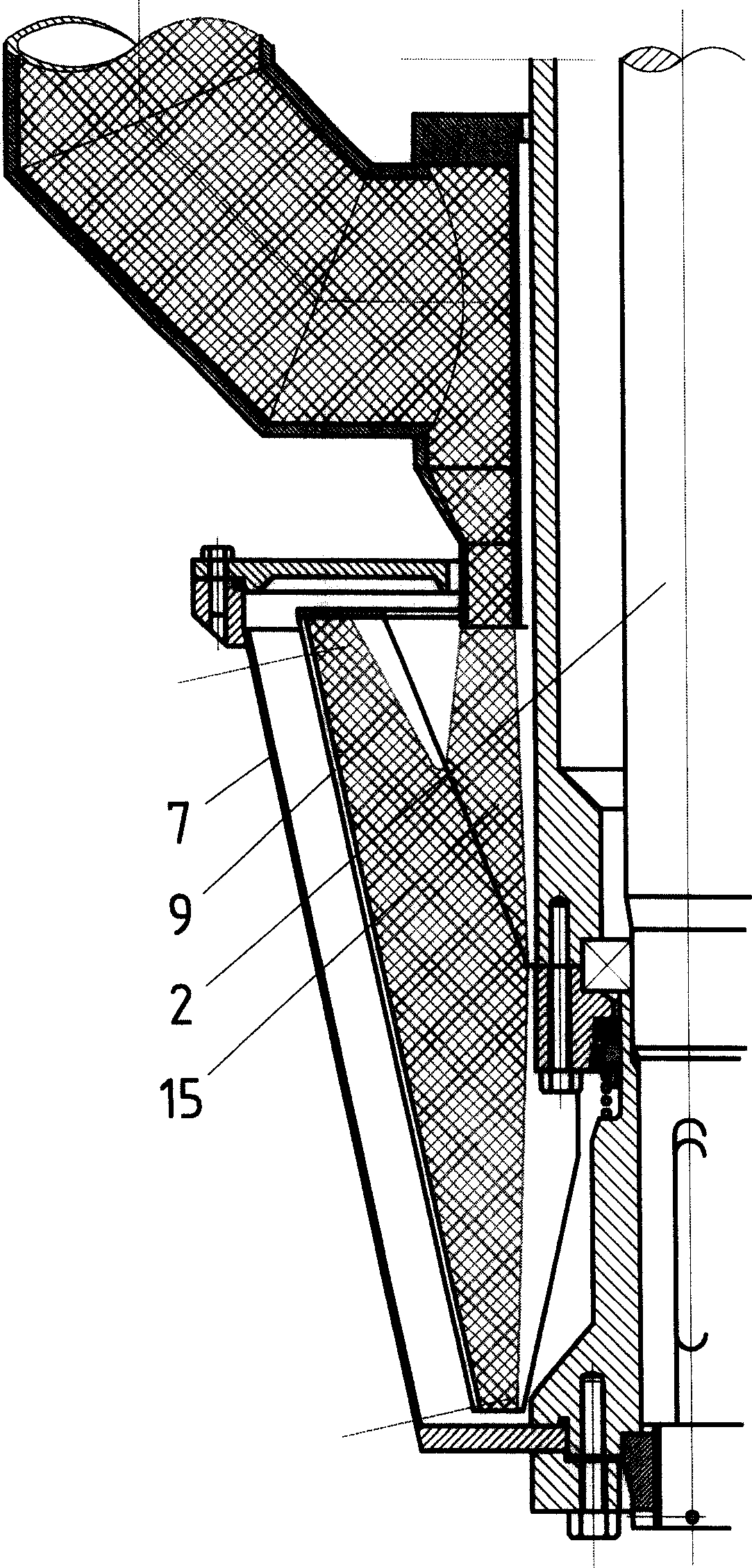

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] The granulation spray head of the present invention is suitable for a differential rotary granulation mechanism. The differential rotary granulation mechanism has two coaxially arranged working main shafts, that is, the inner rotating shaft 2 and the outer rotating shaft 3. The inner rotating shaft 2 drives the granulation spray head. The outer rotating shaft 3 drives the nozzle inner parts distributing mechanism for distributing materials. According to the process requirements, the two main shafts rotate asynchronously and differentially in the same direction or in reverse differentially through their respective transmission mechanisms.

[0020] Such as figure 1 As shown, the granulation nozzle of the present invention is arranged at the lower end of the differential rotary granulation mechanism, including the nozzle housing 7. The no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com