CoenzymeQ 0quinhydrones normal pressure catalytic hydrogenation preparation process and its refining method

A technology of catalytic hydrogenation and preparation process, which is applied in the direction of chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as recrystallization, large product loss, and difficult operation, so as to improve yield and purity, avoid Product loss, cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

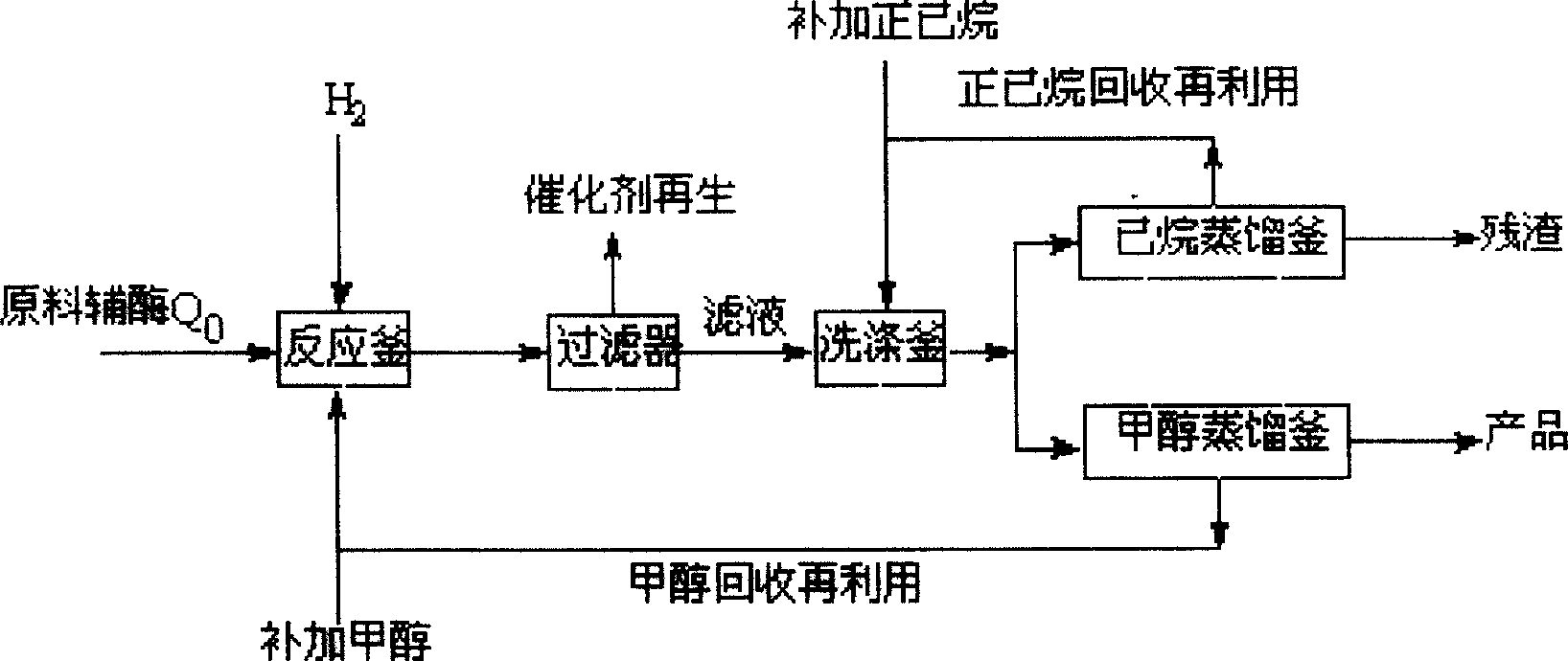

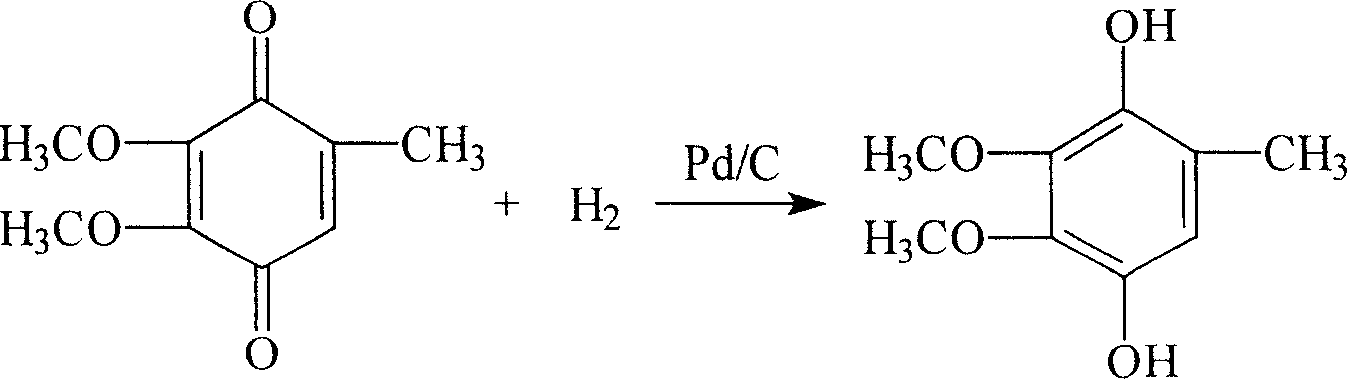

[0012] figure 1 In, 2,3-dimethoxy-5-methyl-1,4-benzoquinone (coenzyme Q 0 ) 18.2g was dissolved in 60ml of absolute ethanol, 1g of palladium carbon catalyst was added, and hydrogenation reaction was carried out under normal pressure. Remove the solvent, obtain 17.5g coenzyme Q 0 Hydroquinone, yield 95%. The melting point is 77-78°C.

[0013] 5 g of 2,3-dimethoxy-5-methyl-1,4-benzoquinone was dissolved in 200 mL of methanol, and hydrogenated with a palladium black (5% palladium) catalyst at a pressure of 50 psi. After the hydrogen absorption stopped, the catalyst was filtered off, and the filtrate was concentrated under reduced pressure. The residue was dissolved in 35 mL of water containing some sulfur dioxide, and the solution was cooled overnight. Collect the precipitated crystals to obtain coenzyme Q 0 Hydroquinone 2.88g, melting point 77~78℃. After the filtrate was concentrated, 0.78 g of the product was also recovered, with a total yield of 73%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com