Method for determining composition of pore fluid of sulphoaluminate cement hardening slurry

A technology of sulfoaluminate cement and pore liquid, applied in the direction of removing certain components in weighing, measuring devices, instruments, etc., can solve problems such as gaps and ion concentration drop, achieve good repeatability and avoid high-pressure operation , to avoid the effect of ion concentration drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

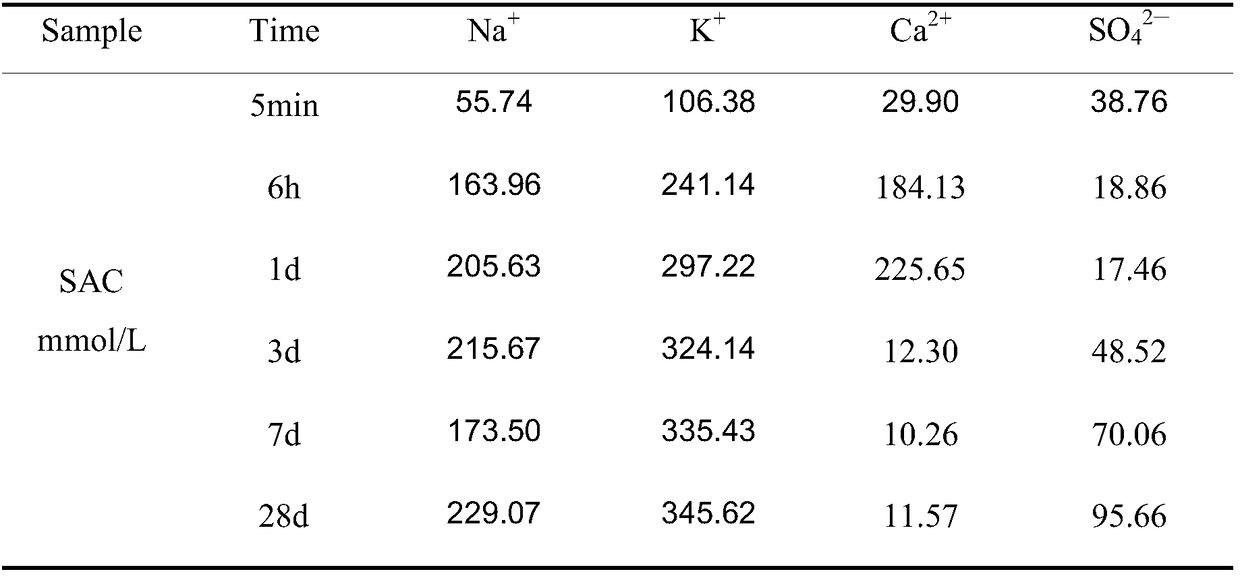

[0028] The following examples take the 42.5 grade quick-hardening sulfoaluminate cement produced by a company in Shandong as an example, and the following steps are used to determine the composition of the cement pore fluid:

[0029] 1) Sample preparation: add water to sulphoaluminate cement at a water-binder ratio of 0.5, stir in a slurry mixer for 2 minutes, and prepare a 40×40×160mm specimen according to the standard. Remove the mold after 6 hours, seal it with a plastic bag and place it in the standard maintenance until the specified age.

[0030] 2) Determination of free water content: cut off one-third from the test piece, weigh its weight W 1 After that, it is quickly crushed and placed in an oven, and dried at 60°C to a constant weight W 2 . Then the free water content w is: w=(W 1 -W 2 ) / W 1 ×100%.

[0031] 3) Liquid phase extraction: crush the remaining test pieces with a pressure testing machine, and further grind and pulverize them with a mortar. Pass the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com