Patents

Literature

57 results about "Coenzyme M" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coenzyme M is a coenzyme required for methyl-transfer reactions in the metabolism of methanogens. The coenzyme is an anion with the formula HSCH 2CH 2SO− 3. It is named 2-mercaptoethanesulfonate and abbreviated HS–CoM. The cation is unimportant, but the sodium salt is most available. Mercaptoethanesulfonate contains both a thiol, which is the main site of reactivity, and a sulfonate group, which confers solubility in aqueous media.

Toothpaste containing coenzyme Q10 and preparation method thereof

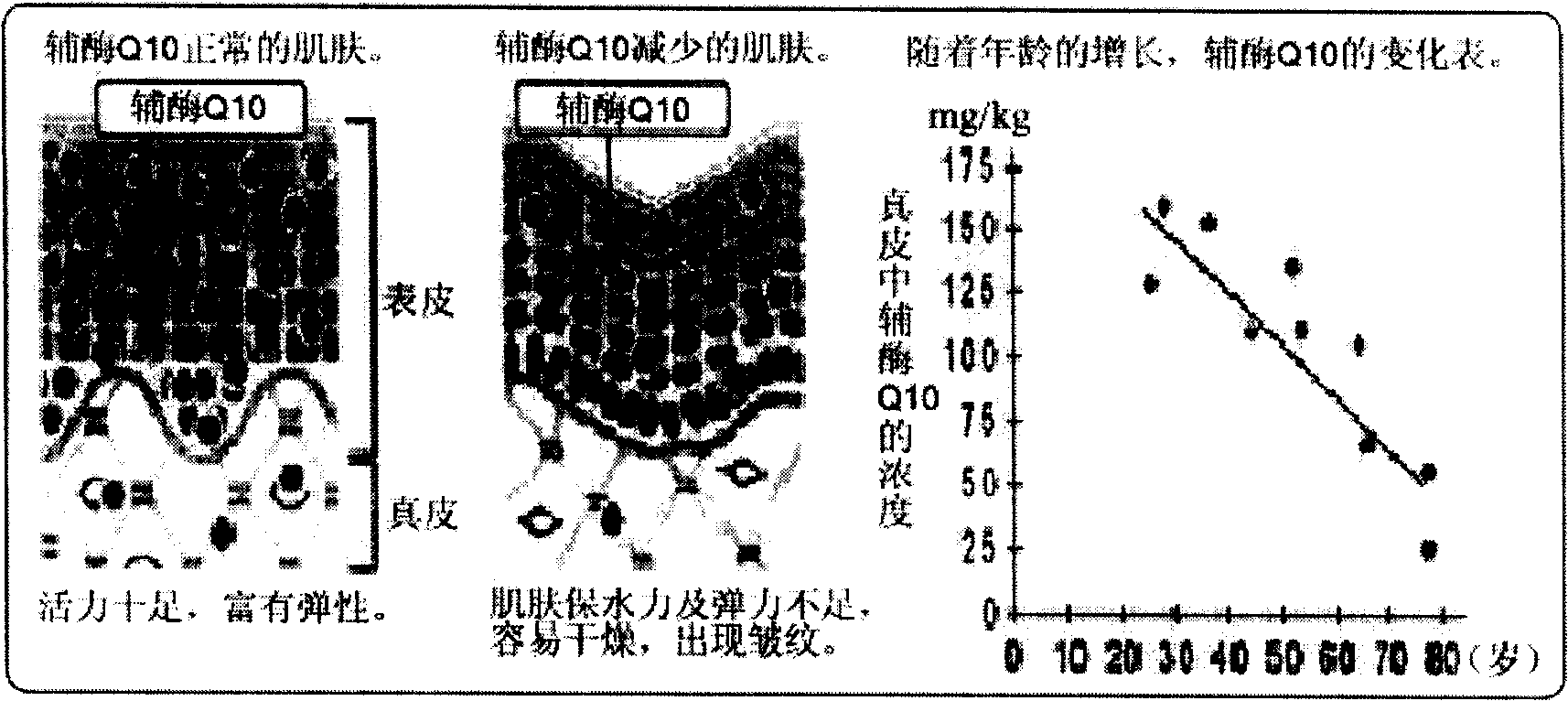

ActiveCN101502482APrevent atrophyImprove organizational vitalityCosmetic preparationsToilet preparationsFoaming agentOral ulcers

The invention relates to a toothpaste containing coenzyme Q10 and a preparation method thereof, in particular to a composition of toothpastes, belonging to the field of oral healthcare products; based on weight percentage, the coenzyme Q10 in the toothpaste is 1-2% and Chinese herbal extract is 0.5-2%; the rest of accessories are conventional materials for preparing toothpastes. The formulation proportion of the components in the toothpaste is preferably as follows: 2% of coenzyme Q10 mixture, 0.7% of Chinese herbal extract, 35% of abradant, 1.5% of bonding agent, 35% of wetting agent, 0.2% of flavoring agent, 2.5% of foaming agent, 1.5% of essence and 21.6% of deionized water. The toothpaste containing coenzyme Q10 has the healthcare functions the same as the common toothpastes, such as brightening and cleaning the teeth, stopping bleeding of gums and healing oral ulcer; besides, the coenzyme Q10 and Chinese herbal extract permeate the gum cell membrane so that the gum cell obtains energy and tissue vigor is strengthened, thereby essentially conserving the gums, preventing periodontitis, gingivitis and gingival atrophy to reach the aim of strengthening the gums and fixing teeth.

Owner:玉溪健坤生物药业有限公司

Method for producing a coenzyme Q10/gamma-cyclodextrin complex

InactiveUS6861447B2The way is simple and fastCosmetic preparationsBiocideΓ cyclodextrinCo enzyme q10

A method is provided for producing a coenzyme Q10 / γ-cyclodextrin complex. This method provides that a mixture of γ-cyclodextrin and coenzyme Q10 is treated by homogenisation and inputting energy.

Owner:WACKER CHEM GMBH

Composition of high absorbability for oral administration comprising oxidized coenzyme q10

InactiveUS20080145411A1Promote oral absorptionPromote absorptionBiocidePowder deliveryOral medicationNutrition supplementation

The present invention provides a method of increasing the absorbability of oxidized coenzyme Q10 by preparing the oxidized coenzyme Q10 as a composition in the presence of a lysolecithin and an oil and fat. The composition of the present invention comprising oxidized coenzyme Q10, a lysolecithin and an oil and fat, wherein the weight ratio of the lysolecithin to the oxidized coenzyme Q10 is not less than 0.7, shows superior absorption of oxidized coenzyme Q10 and can be utilized for food, food with nutrient function, food for specified health uses, nutritional supplement, nutritional product, animal drug, beverage, feed, pet food, cosmetics, pharmaceutical product, therapeutic drug, preventive drug and the like.

Owner:KANEKA CORP

Composition comprising coenzyme q10

InactiveUS20090004170A1Easy to waterOrganic active ingredientsCosmetic preparationsSolubilityWater dispersible

The present invention provides a composition superior in water-dispersibility / solubility, workability and tabletability, which contains coenzyme Q10, casein, and a saccharide other than polysaccharides, at a particular ratio. The composition can be utilized for food, food with nutrient function claims, food for specified health uses, nutritional supplement, nutritional product, animal drug, drinks, feed, pharmaceutical product, quasi-drug, cosmetic and the like.

Owner:KANEKA CORP

Method of stabilizing reduced coenzyme Q10 and method of acidic crystallization

InactiveUS7169590B2Favorably protected against oxidationHigh yieldBiocidePeptide/protein ingredientsStrong acidsSolvent

The present invention relates to a method of efficiently producing reduced coenzyme Q10 having excellent qualities which is useful as an ingredient in foods, functional nutritive foods, specific health foods, nutritional supplements, nutrients, animal drugs, drinks, feeds, cosmetics, medicines, remedies, preventive drugs, etc. This method is suitable for industrial production thereof.It is possible to handle reduced coenzyme Q10 in state of being protected from oxidation by molecular oxygen by bringing the reduced coenzyme Q10 in contact with a solvent containing a strong acid. Furthermore, when reduced coenzyme Q10 is crystallized in the presence of a strong acid, crystallization can be carried out while the formation of oxidized coenzyme Q10 as a by product is minimized, and, then high-quality crystals thereof can be produced.

Owner:KANEKA CORP

Stabilization method of reduced coenzyme q10

ActiveUS20070258966A1Improve stabilityPromote absorptionCosmetic preparationsHydroxy compound active ingredientsCoenzyme Q10Coenzyme A

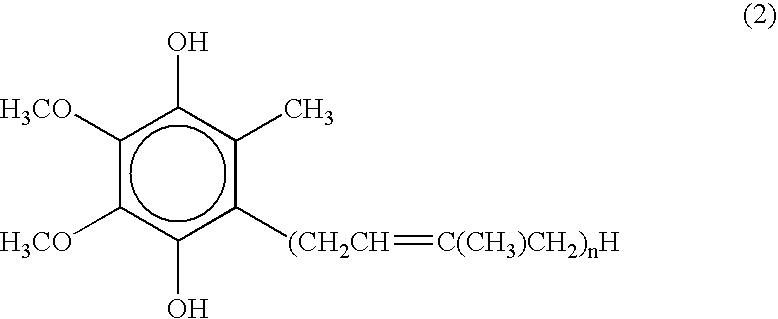

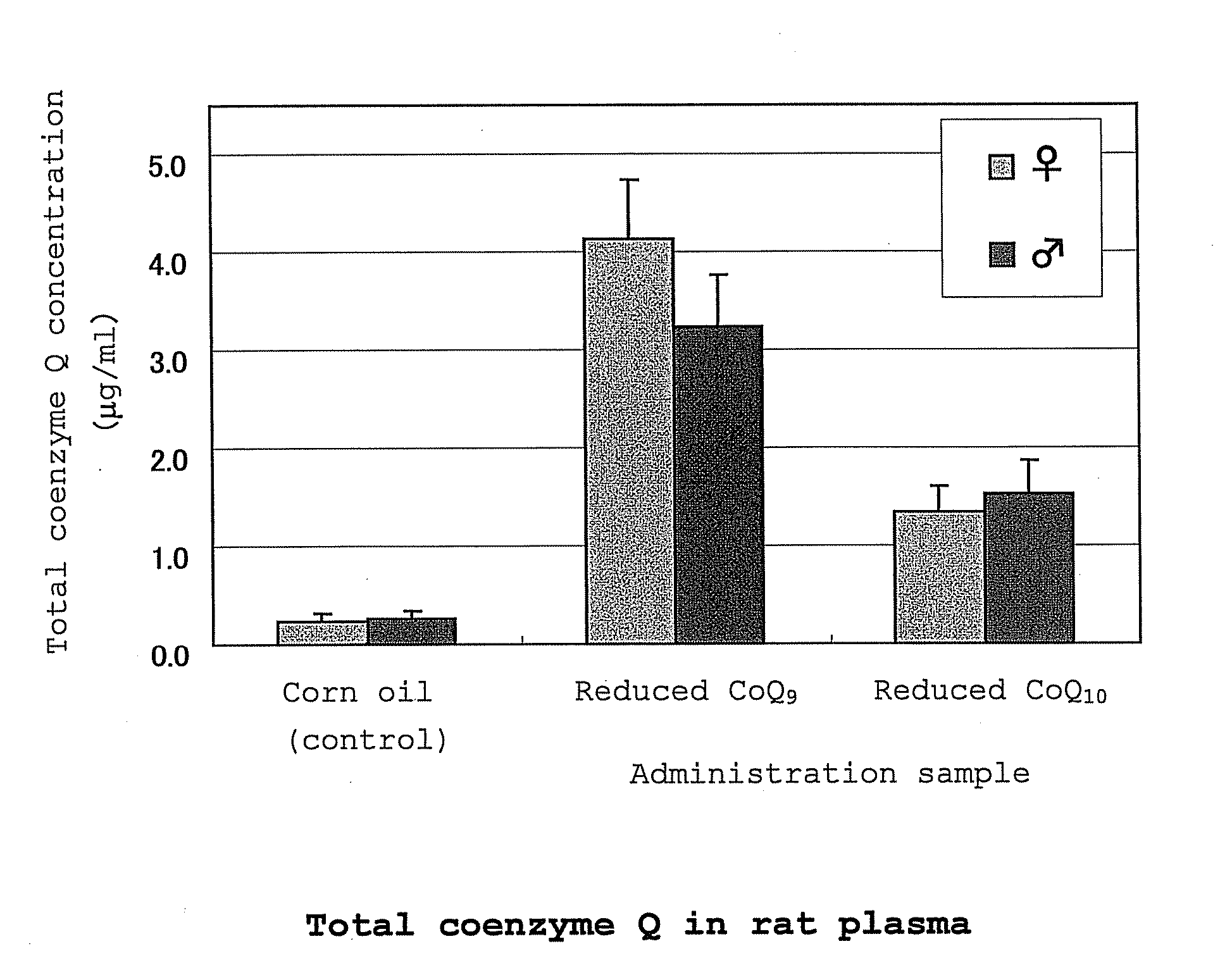

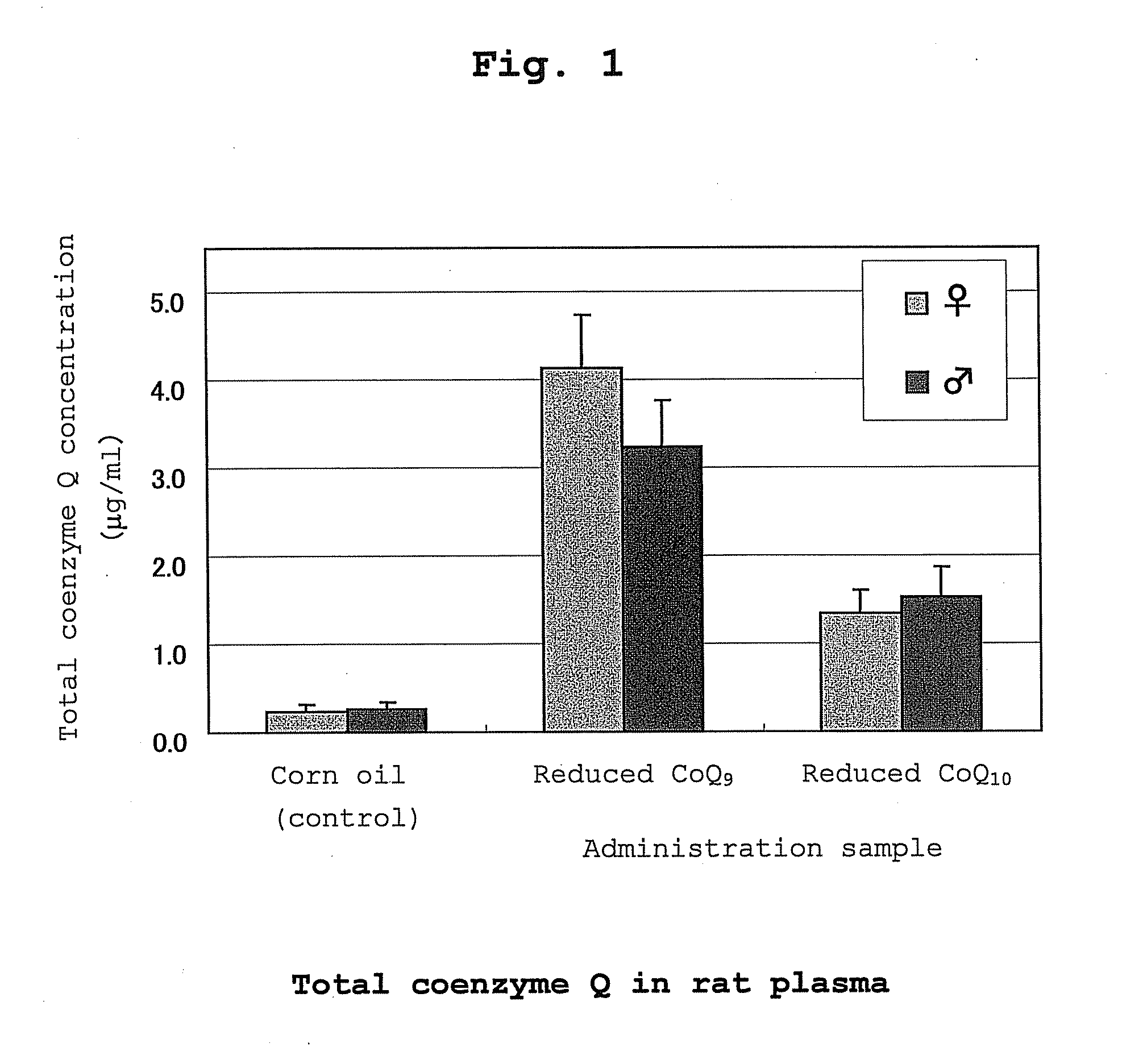

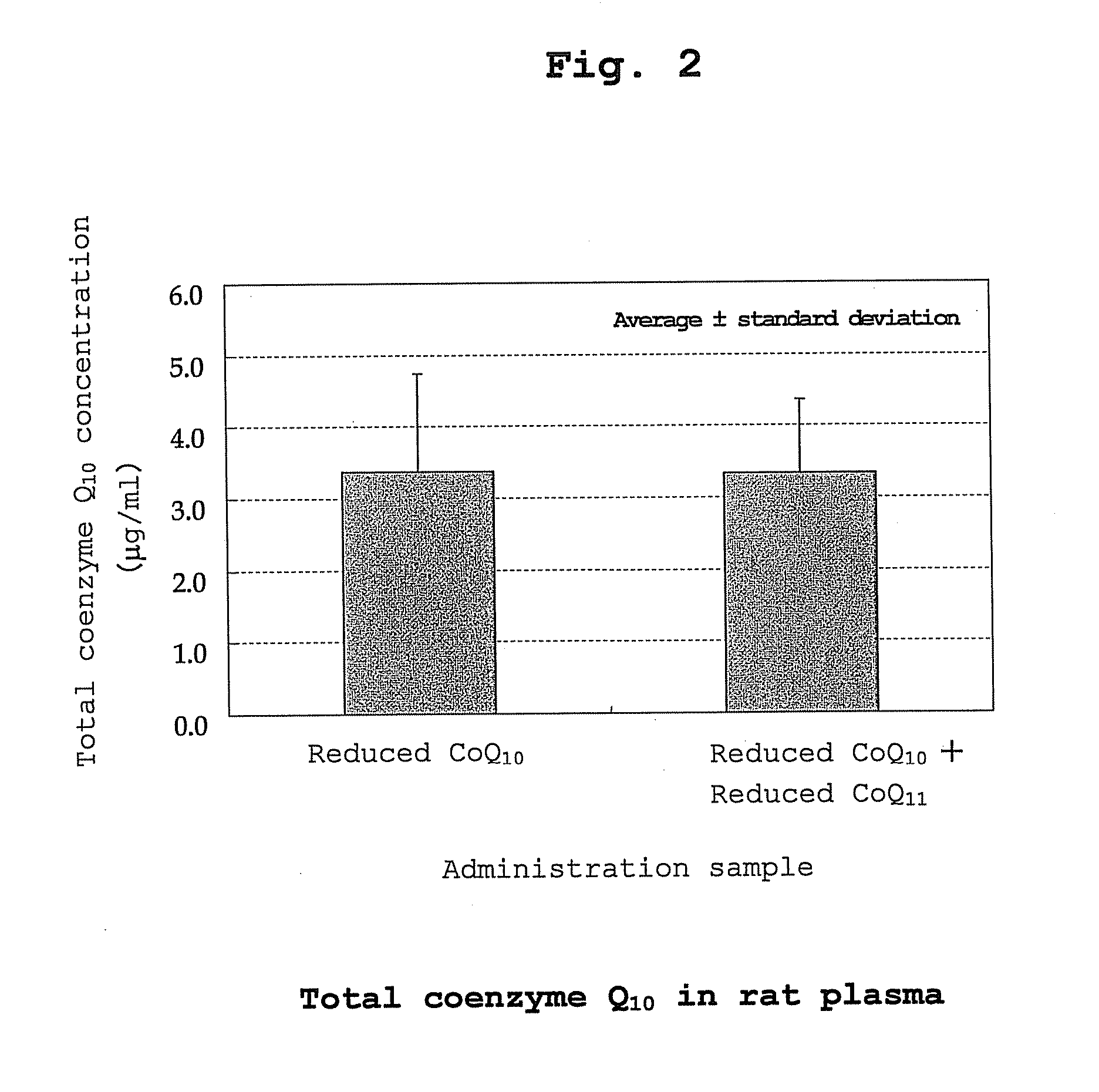

The present invention provides a method for stabilizing reduced coenzyme Q10, which is useful as a food, nutritional product, nutritional supplement, animal drug, drink, feed, cosmetic, pharmaceutical product, therapeutic drug, prophylactic drug and the like. The present invention also provides a method of producing a reduced coenzyme Q10-containing composition which includes the co-presence of reduced coenzyme Q10 and reduced coenzyme Q9 and / or reduced coenzyme Q11.

Owner:KANEKA CORP

Reduced coenzyme Q10 essence oil and preparation method thereof

InactiveCN101732201AImprove product qualityCosmetic preparationsToilet preparationsVegetable oilSolvent

The invention discloses a method for conveniently and effectively producing reduced coenzyme Q10 essence oil by using high-purity reduced coenzyme Q10. The reduced coenzyme Q10 essence oil has excellent quality, has efficiency eight times than that of an oxidized coenzyme Q10 and can be used for cleaning and nursing skin of each part of face, eyes, breasts, abdomen, hands and body. The method is suitable for industrial production. In a method for producing soft capsule or bottled reduced coenzyme Q10 essence oil by adding vegetable fat as a solvent and essence, at least one type of vegetable oil is used as the solvent and at least one type of essence is used for blending. At least one type of bottled capsule is used as the package, so a functional component of reduced coenzyme Q10 can be protected from performing molecular oxidation action to obtain a high-quality reduced coenzyme Q10 essence oil product.

Owner:玉溪健坤生物药业有限公司

Coenzyme Q10 pharmaceutical composition

InactiveCN101480381AOvercoming easily turbid precipitationOvercoming qualityOrganic active ingredientsPowder deliveryPolyoxyethylene castor oilMonoglyceride

The invention discloses a coenzyme Q10 pharmaceutical composition which mainly comprises components: (1) coenzyme Q10 is active ingredient; (2) one or multiple of polyethylene 15-oxhydryl glycol stearate (Solutol HS 15), polysorbate, PEG, poloxamer, and polyoxyethylene castor oil derived products are solubilizer; (3) one or multiple of midchain monoglyceride and derived products thereof, medium saturated or unsaturated fatty acid are oil component; and (4) injection water is solvent. One or multiple of excipient, chemical inhibitor, and osmotic pressure regulator are added for preparing injection and freeze drying agent. Compared with the traditional coenzyme Q10 pharmaceutical composition, the injection administration coenzyme Q10 pharmaceutical composition has better storage and transportation stability and higher clinical application safety and patient compliance. The injection has simple preparation process, convenient quality control, lower production cost and convenient industrial production.

Owner:郑微

Coenzyme Q10 water dispersion and preparation method thereof

ActiveCN101288641AHigh requirements for transparencyEvenly dispersedOrganic active ingredientsNervous disorderAntioxidantPolyethylene glycol

The invention relates to a coenzyme Q10 water dispersion and a preparation method thereof, which is composed of coenzyme Q10, pectin substances, emulsifier, polyethylene glycol or poloxamer and other excipients which are all edible, the hot-melt mixture of the coenzyme Q10 and the polyethylene glycol or the poloxamer is further mixed with the mixture of the pectin substances, sugar, the emulsifier and soluble starch, the heating and the heat preservation are carried out, after that, a colloidal mill and a high-pressure homogenizer or a high-speed shear emulsion mixer are used for homogenizing to prepare an even colloid; and the coenzyme Q10 water dispersion is finally prepared by spray drying. The coenzyme Q10 water dispersion and the preparation method are characterized in that the bioavailability is high, all the used excipients are edible, the safety is good, the whole preparation process does not use any organic solvent or antioxidant, thus having no pollution on the product and the environment caused by the organic solvents, having small production difficulty and being applicable to the industrial production.

Owner:浙江一新制药股份有限公司

Emulsion including coenzyme Q10 and vegetal marrow and preparing method thereof

InactiveCN101032459AAnti-agingWith whiteningCosmetic preparationsToilet preparationsAdditive ingredientOil phase

The present invention is one kind of emulsion containing coenzyme Q10 and plant essence and its preparation process. The emulsion consists of coenzyme Q10 0.01-2 wt%, licorice extracting solution 0.5-5 wt%, skullcap root extracting solution 0.2-4 wt% and ginsenoside 0.02-2 wt%, as well as clove oil, jasmine oil, rose oil, emulsion matrix and emulsifier. Its preparation process includes the following steps: adding coenzyme Q10 into oil phase, adding plant extracts into water phase, separately heating the oil phase and the water phase to 75 deg.c, adding the oil phase slowly into the water phase via stirring, cooling to about 50 deg.c and adding clove oil, jasmine oil and rose oil via stirring to obtain the emulsion. The emulsion containing coenzyme Q10 and plant essence has functions of resisting senility, making skin fair and delicate, resisting oxidation, resisting bacteria and diminishing inflammation.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

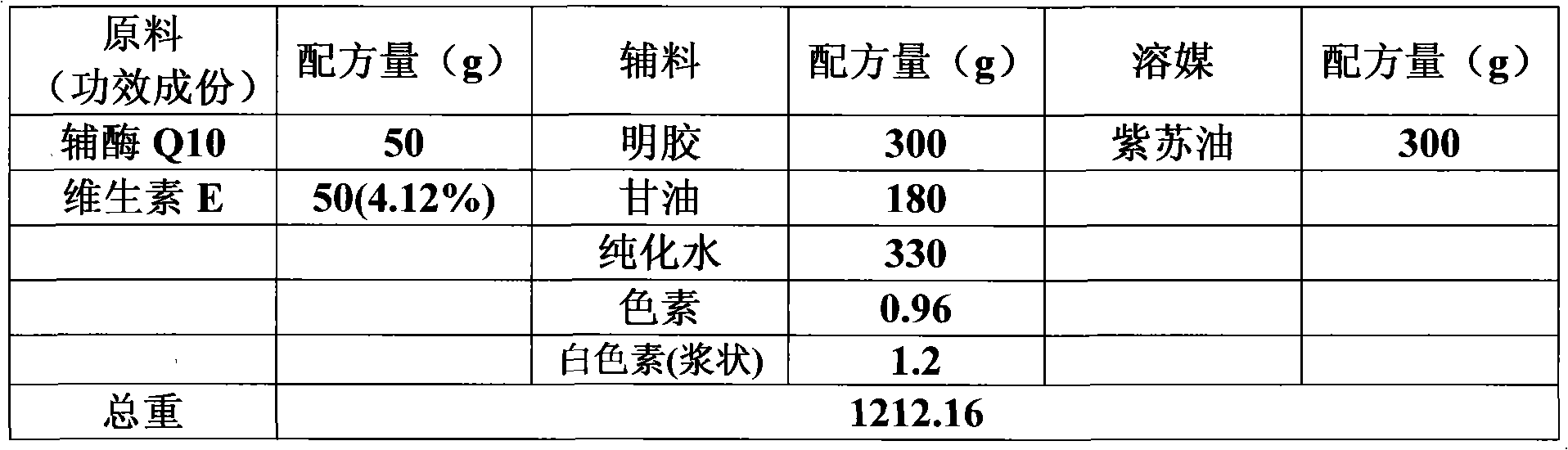

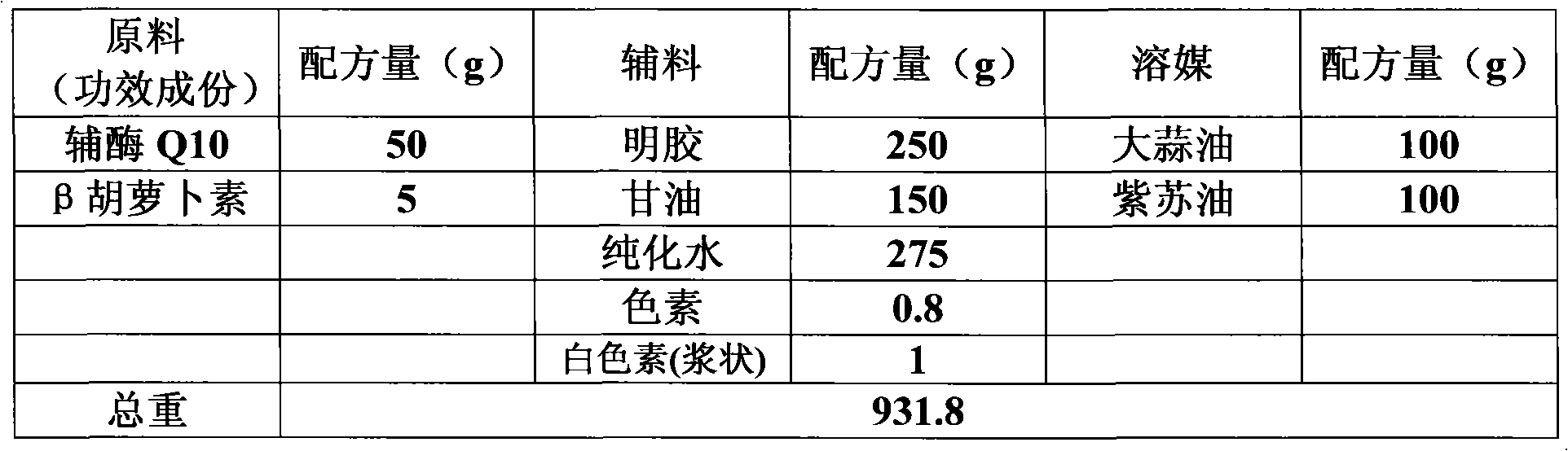

Coenzyme Q10 composite soft capsule and preparation method thereof

ActiveCN101897440AGuaranteed qualityAnti-Aging ProtectionFood preparationWater bathsAdditive ingredient

The invention relates to a coenzyme Q10 composite soft capsule and a preparation method thereof, belonging to the technical field of health-care foods. The coenzyme Q10 composite soft capsule comprises a capsule shell and capsule content, wherein the capsule content comprises the following raw materials in proportions by weight: coenzyme Q10: zinc lactate: sodium selenite: vitamin E: corn oil =1:(0.8-1.6):(0.001-0.005):(1.5-3.5):(15-25); and the soft capsule shell comprises the following ingredients of gelatin, glycerol and pure water. The preparation method comprises the following steps of: preparing the capsule materials: heating the gelatin, the glycerol and the water in water bath to 50-95 DEG C for dissolving according to the proportions of (0.5-2):(0.2-0.8):(0.5-1.5) , and preserving the temperature at 45-80 DEG C; taking the zinc lactate and the sodium selenite according to the formula amount, evenly mixing in an equivalent progressive-increase way, then evenly mixing with the coenzyme Q10, and carrying out ultramicro crushing; putting the natural vitamin E and the corn oil in and stirring in 500-2000rpm to obtain mixed oil, adding fine mixed powder and evenly stirring; and preparing the coenzyme Q10 composite soft capsule by using an auto-rotating capsule rolling machine. the invention has the advantage of greatly increasing the stability of the coenzyme Q10.

Owner:BEIJING DAWN AEROSPACE BIO TECH

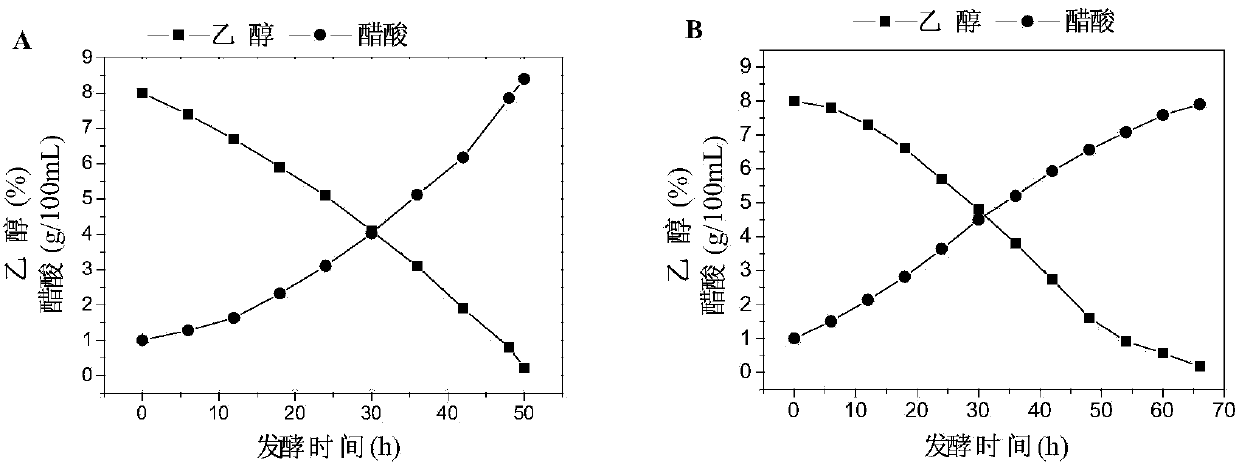

Genetic engineering acetic acid bacteria of overexpressing coenzyme PQQ (pyrroloquinoline quinone) synthetic proteins and application of bacteria

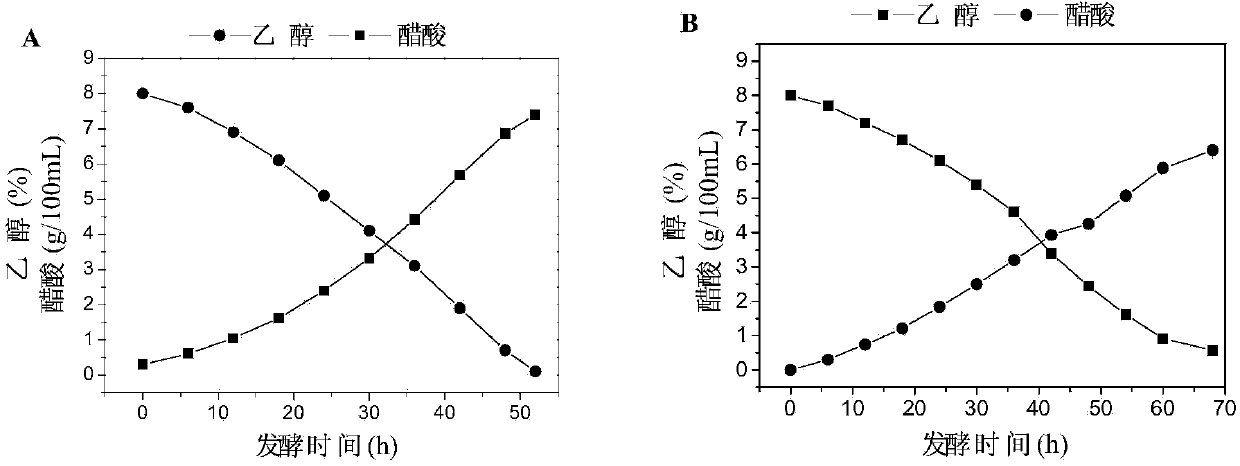

ActiveCN103740629AIncrease concentrationSimultaneous synthesisBacteriaMicroorganism based processesEthanol dehydrogenaseIn vivo

The invention relates to a building method of genetic engineering acetic acid bacteria of recombinantly expressing coenzyme PQQ (pyrroloquinoline quinone) synthetic proteins. The PQQ biosynthetic proteins are PqqA, PqqB, PqqC, PqqD, PqqE, and functional equivalents thereof. An alcohol dehydrogenase promoter from acetobacter pasteurianus and a coenzyme PQQ synthetic protein gene cluster pqqABCDE sequence are orderly connected into plasmids which can be stably copied in the acetic acid bacteria, so as to recombine pBBR-padh-pqq; recombinant plasmid pBBR-padh-pqq is transferred into the acetic acid bacteria, so as to obtain the genetic engineering acetic acid bacteria of overexpressing the coenzyme PQQ synthetic proteins. Thus, the concentration of in vivo coenzyme PQQ of the acetic acid bacteria in the fermentation process of acetic acid is improved. Acetic acid fermentation is carried out by using the genetic engineering bacteria disclosed by the invention, the fermentation delay phase can be shortened, and the fermentation rate of the acetic acid is increased. Thus, the production cost is reduced.

Owner:TIANJIN UNIV OF SCI & TECH

Coenzyme Q10 precursor liposome and preparation method

InactiveCN1437931AImprove stabilityPlace stableCosmetic preparationsToilet preparationsFreeze-dryingLiposome

The present invention relates to a coenzyme Q10 liposome containing ceramide, its preparation method and application. Said invention also contains other lipid component in its structure, and can be made into granular material by means of freeze-drying or spray-drying process, then further freeze-dried to obtain the solid preparation. Before use, a certain quantity of water is mixed with it, and shaken, so that the coenzyme Q10 liposome can be obtained. Said invention can promote transdermal absorption of coenzyme Q10 raise the application effect of coenzyme Q10 in the cosmetics, and raise stability of coenzyme Q10 and liposome.

Owner:SHANGHAI JAHWA UNITED

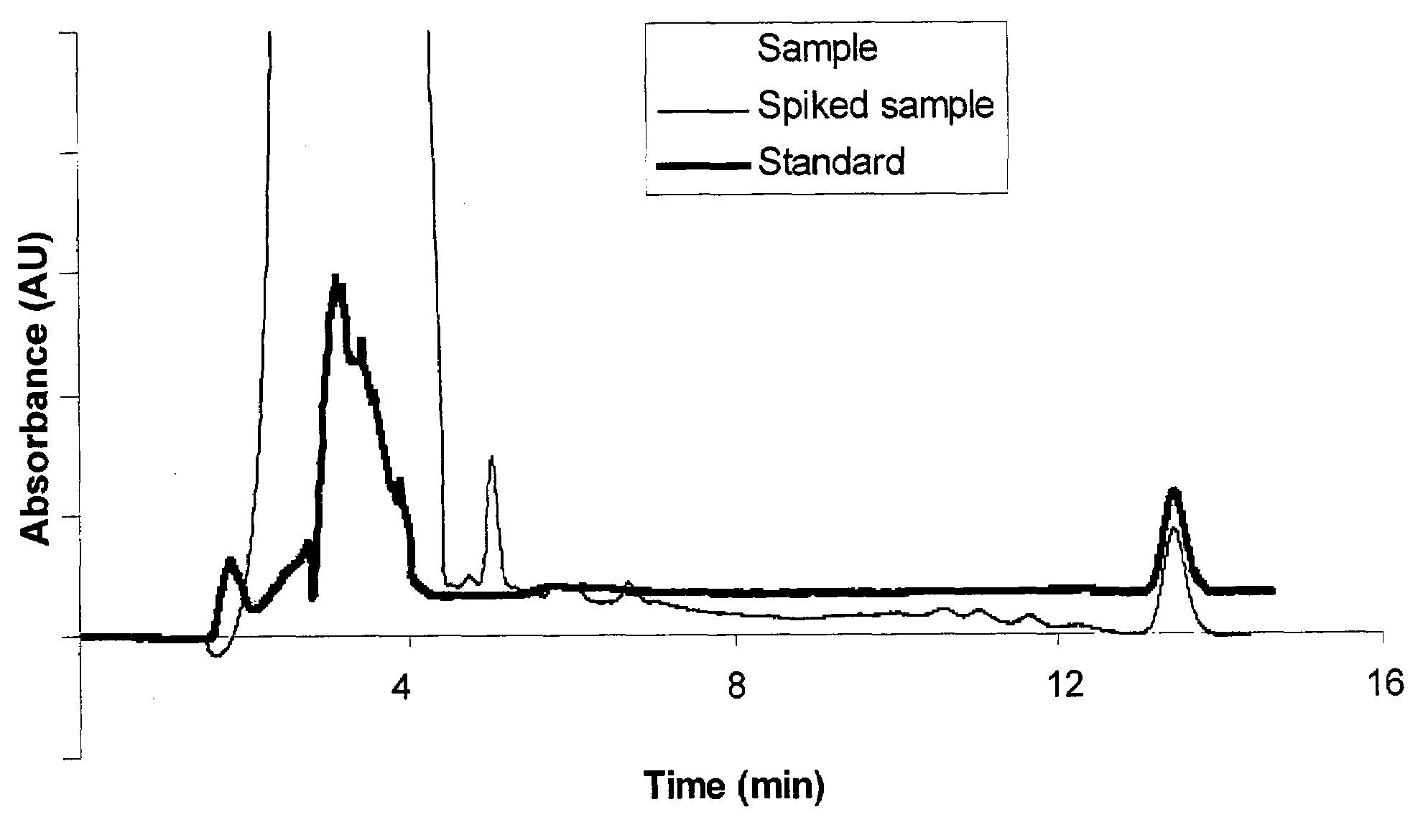

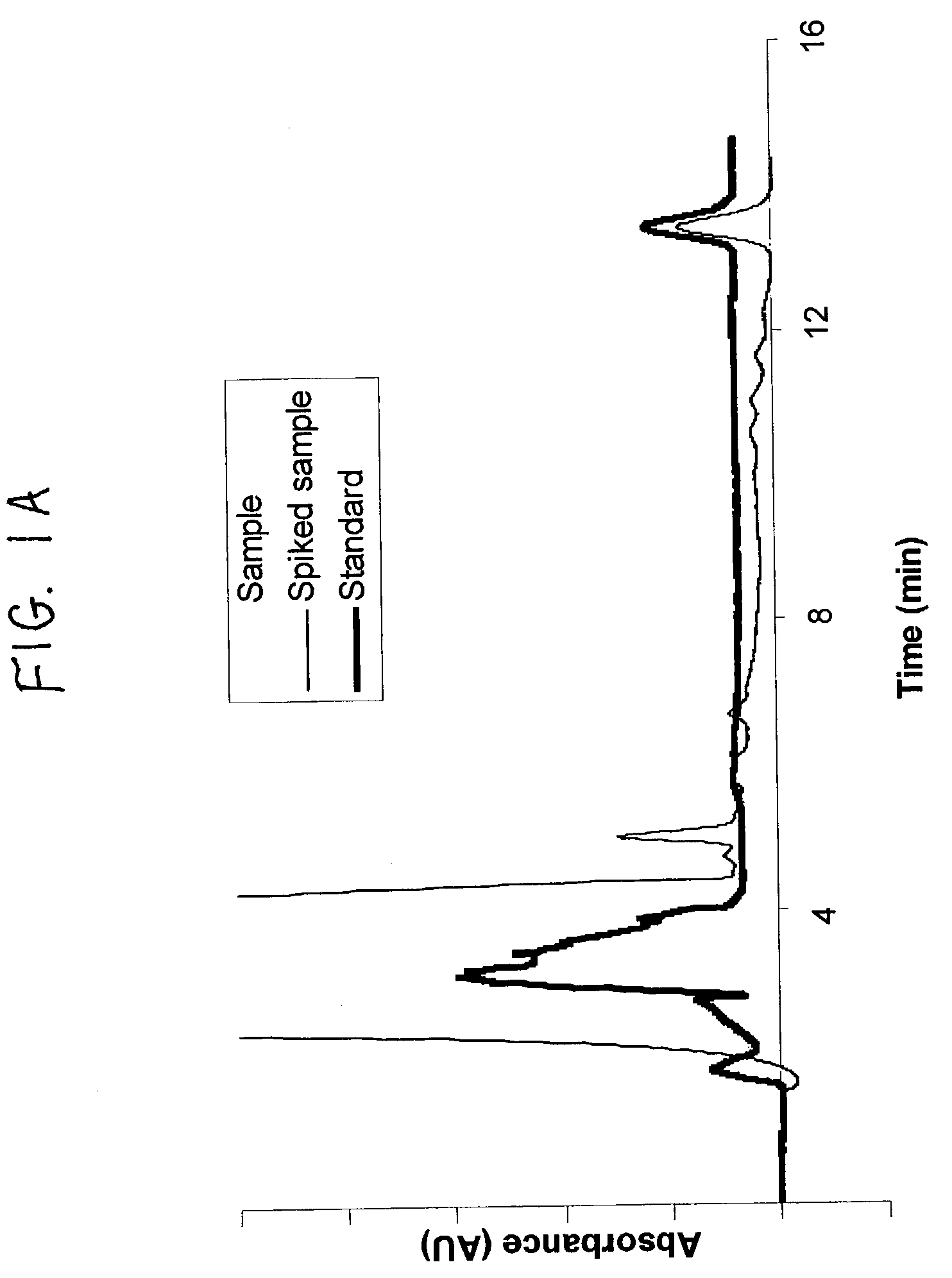

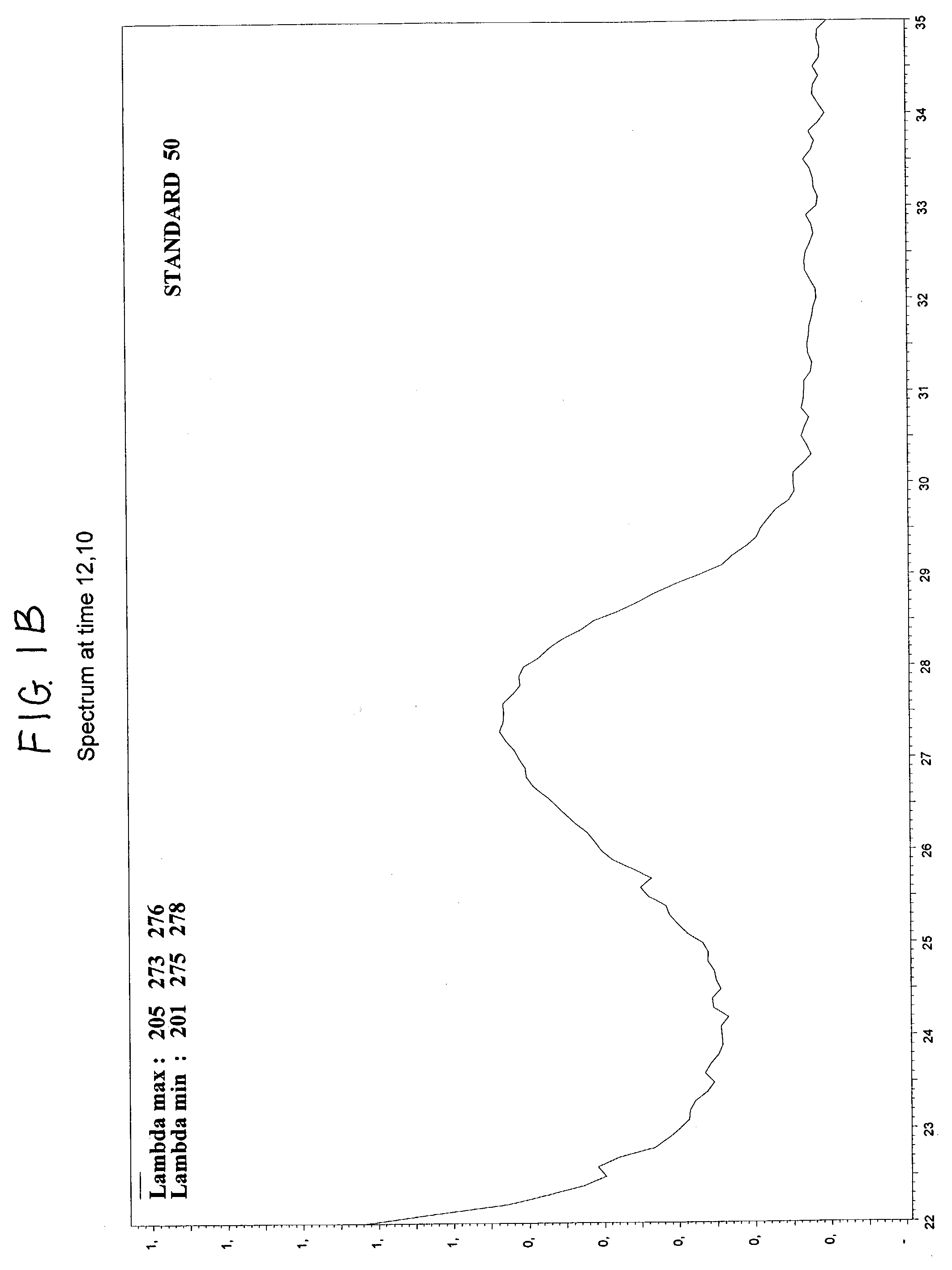

Method to assay coenzyme Q10 in blood plasma or blood serum

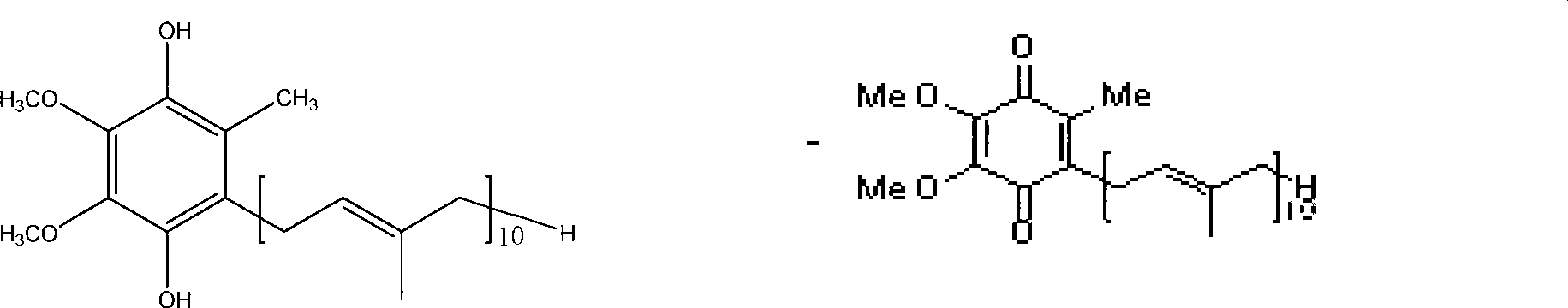

InactiveUS7303921B2Component separationMicrobiological testing/measurementPara-BenzoquinoneCoenzyme M

A method is described for determining CoQ10 concentrations in plasma samples. CoQ10 in the plasma sample is oxidized by treating the sample with an oxidizing agent having a redox potential higher than the redox potential of CoQ10, such as, for example, para-benzoquinone. Following oxidation of the CoQ10, the CoQ10 in the plasma sample is extracted with an alcohol, such as, for example, 1-propanol. The alcohol extract is analyzed using direct injection into the HPLC apparatus. This method achieves a rapid, accurate analysis of plasma CoQ10 levels, which can be used for monitoring the bioavailability of orally administered CoQ10 used as a food supplement or as an adjunctive therapy.

Owner:LITTARRU GIAN PAOLO +3

Freeze dried powder injection of coenzyme Q10 and its preparation process

ActiveCN1593392AImprove bioavailabilityOrganic active ingredientsPowder deliverySolubilityFreeze-drying

The invention discloses a freeze dried injection containing coenzyme Q#-[10], which comprises coenzyme Q#[10] and surface active agent, wherein the surface-active agent is the mixture of Twain and polyoxyl stearate, the medicinal active component being coenzyme Q#-[10], the weight ratio of coenzyme Q#[10] and Twain is 1:1-1:50, the weight ratio of coenzyme Q#[10] and pollyoxyl stearate is 1:1-1:50.

Owner:HAINAN PULIN PHARMA +2

Method of porducing reduced coenzyme Q10 using solvent with high oxidation-protective effect

Owner:KANEKA CORP

Aqueous solution containing coenzyme Q10 nano granule and preparation method thereof

ActiveCN101485626AImprove solubilityImprove stabilityOrganic active ingredientsPharmaceutical delivery mechanismSolubilityOil phase

The invention provides an aqueous solution containing coenzyme Q10 nano-particles, and a preparation method thereof, which belongs to the technical field of inclusion compounds and preparation thereof. The aqueous solution consists of coenzyme Q10, HP-beta cyclodextrin, gamma cyclodextrin and an emulsifier of which the weight ratio is 1:1-100:1-100:0.5-2. The preparation method adopts a process that the HP-beta cyclodextrin and the gamma cyclodextrin are weighed according to that the weight ratio of the coenzyme Q10 to the HP-beta cyclodextrin to the gamma cyclodextrin to the emulsifier is 1:1-100:1-100:0.5-2, are dissolved in water 3 to 10 times the weight of cyclodextrin and heated to be between 40 and 80 DEG C; an oil-phase matrix of the coenzyme Q10 is completely melted, added to an dissolved aqueous phase in a shearing state and shorn for 5 to 30 minutes at a speed of between 5,000 and 20,000 rpm; a solution obtained after shearing is sent into a high-pressure homogenizer and circulated twice to ten times under the pressure of between 50 and 200 MPa, so the liquid is obtained; and the liquid is diluted to a needed concentration under shearing conditions and continues to be homogenized and circulated once to ten times under the high pressure of between 50 and 220 MPa, so that a finished product is obtained. The preparation method has the advantages of greatly increasing the solubility of the coenzyme Q10 and improving the stability of the solution.

Owner:SHENZHOU BIOLOGY & TECH CO LTD

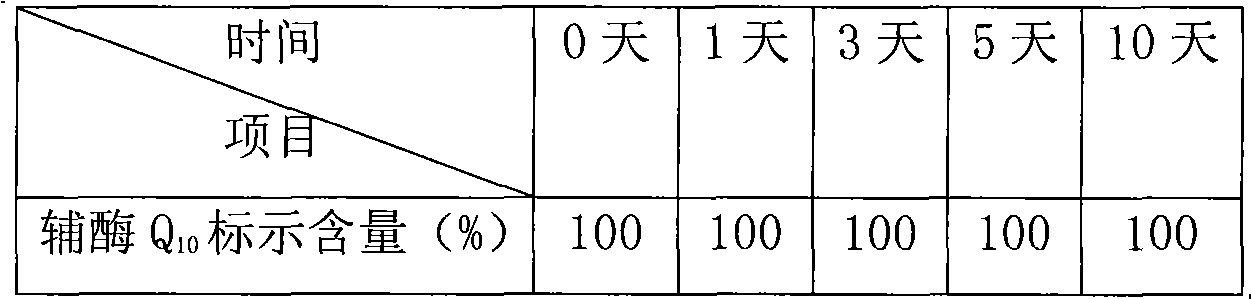

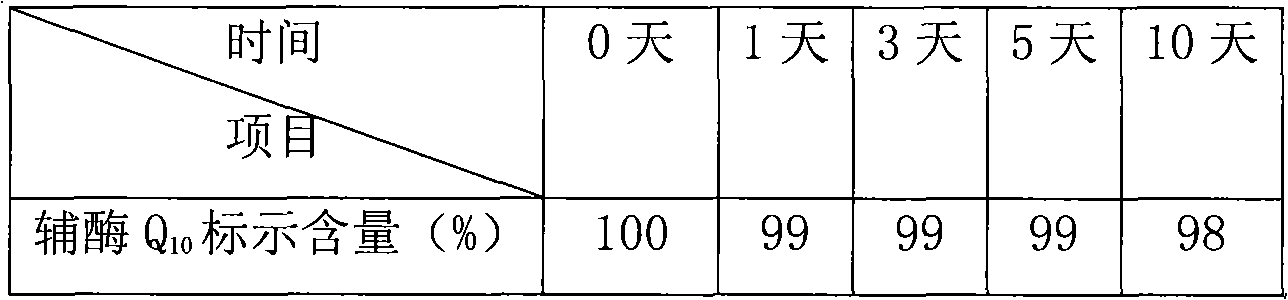

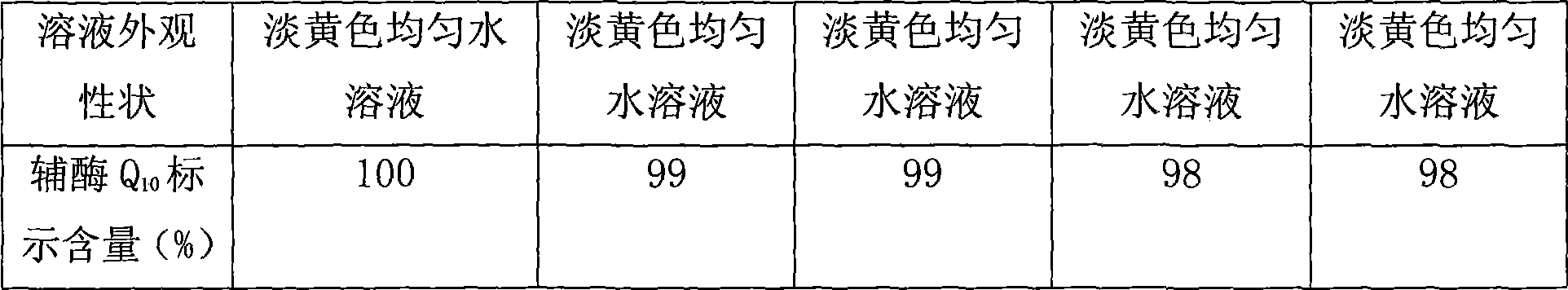

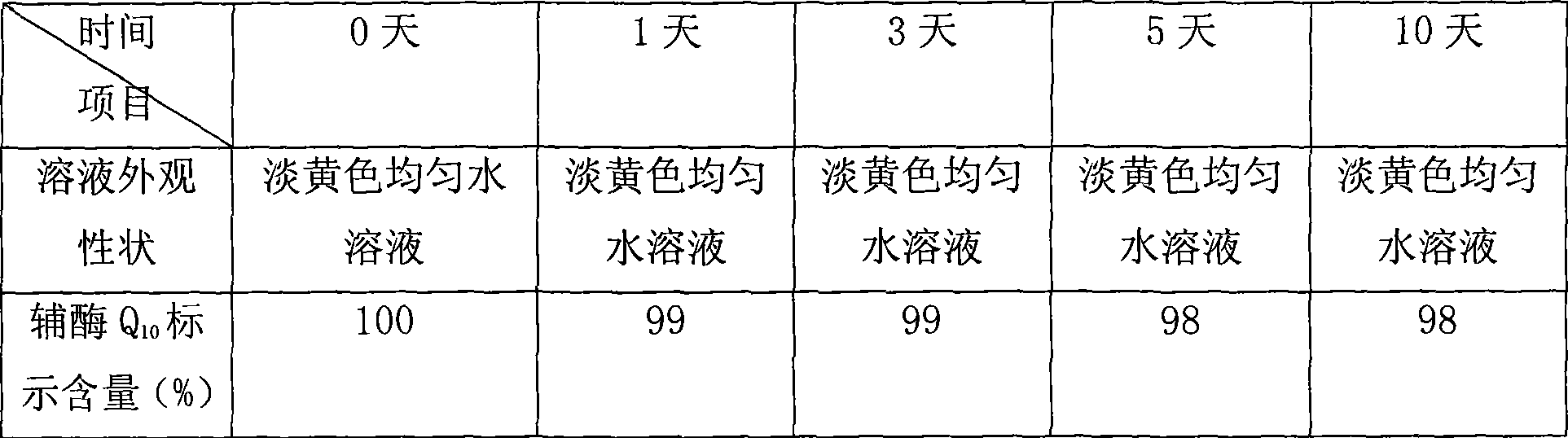

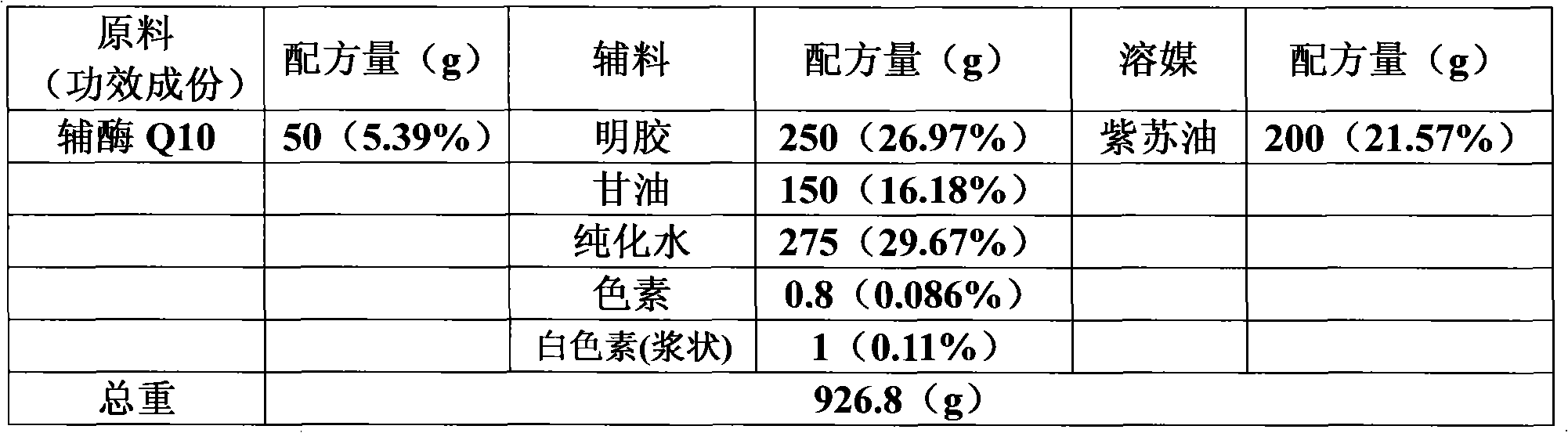

Soft capsule containing coenzyme Q10 and preparation method and application thereof

InactiveCN101849971AHeavy metal active ingredientsHydroxy compound active ingredientsSide effectAdditive ingredient

The invention discloses a Yixingrui Brand soft capsule containing coenzyme Q10 which can improve immunity and fight against cancers, and a preparation method and application thereof. The preparation method comprises the following steps: using 45-55g of raw medicine containing coenzyme Q10 with content more than or equal to 99 percent as an effective ingredient, using 100-300g of perilla herb oil as solvent, preparing the effective ingredient and the solvent into contents at 40-50 DEG C, proportioning 200-300g of gelatin, 100-250g of glycerin, 250-400g of purified water, 0.8-1.2g of pigment and 1-1.2g of pulpy antholeucin to prepare capsule material, adopting sol to prepare the contents and pressing pellets, conducting processes such as drying, pellet picking and the like of a soft capsule preparation technology, and pressing the material medicine into 1000 Yixingrui Brand soft capsules at 50-55 DEG C through a soft capsule pressing technology. The invention is characterized in that the physical efficacy of the coenzyme Q10 is adopted, solvent, vitamin and minerals with collaborative function are screened and the raw medicine is pressed into pellets by adopting the matured Yixingrui Brand soft capsule preparation technology. According to stability tests, evaluative animal safety tests, hygienic tests and efficacy tests, the invention has the advantages of stable form and efficacy ingredients, no toxic and side effects, strong immunologic function, novel anticancer indication effect and promising application prospect.

Owner:玉溪健坤生物药业有限公司

Oil-in-water type emulsion containing coenzyme q10 and process for producing the same

InactiveUS20090142324A1Emulsion stabilizationImprove stabilityBiocideEdible oils/fats ingredientsOrganic acidFlavor

To provide an oil-in-water emulsion composition that prevents separation of coenzyme Q10 and creaming during storage, maintains a stable emulsification state over long term exceeding two weeks, and does not impair flavor or taste. The oil phase of the oil-in-water emulsion composition contains coenzyme Q10, and a complex of an organic acid ester of a monoglyceride and a milk protein is used as the emulsifier.

Owner:KANEKA CORP

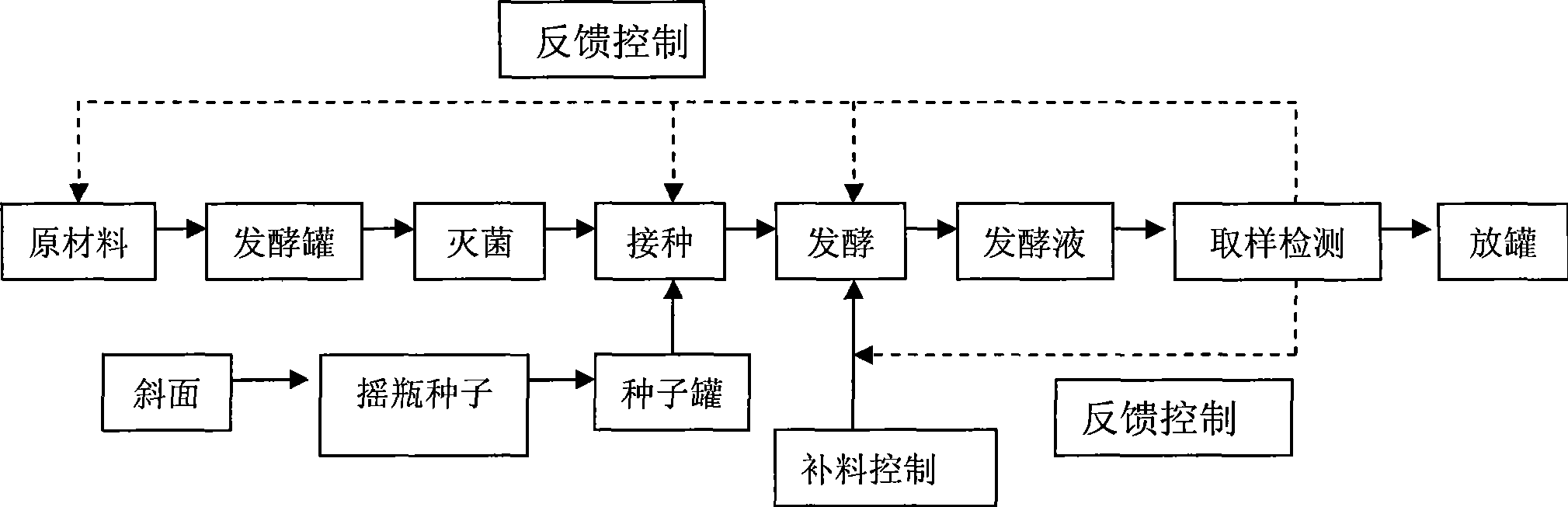

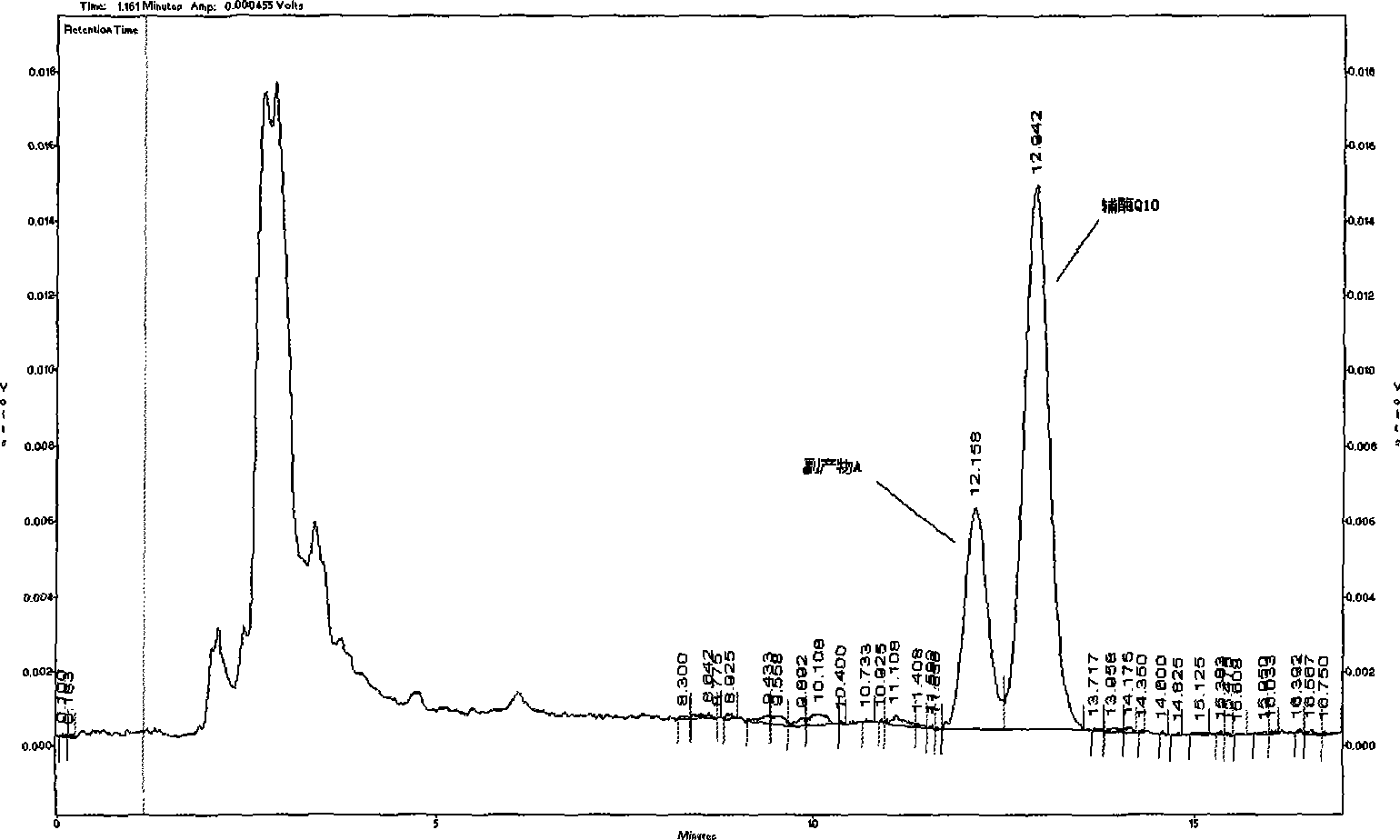

Production and fermentation process of coenzyme Q10

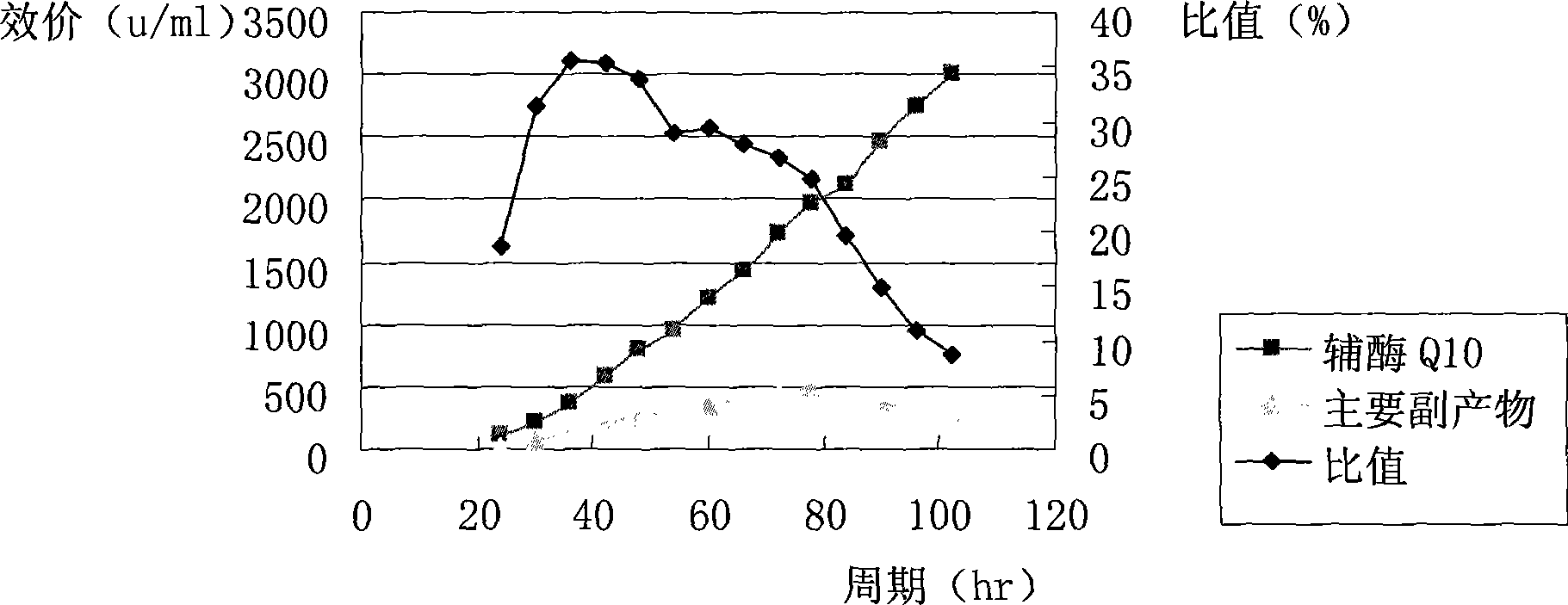

ActiveCN101519681ARaise the level of fermentationImprove time utilizationMicroorganism based processesFermentationMaterial consumptionCellular anabolism

The invention discloses a production and fermentation process of coenzyme Q10. On the premise that the fermentation quality of the coenzyme Q10 is retained, according to the synthesis rate of the main byproduct 5-demethoxylation coenzyme Q10 in the bacteria metabolism process of the coenzyme Q10 as well as the content change thereof, the feedback adjustment is performed on the initial reaction of metabolism, and the speed restriction action is acted on the anabolism, therefore, the feedback adjustment is performed on the accumulation of the product coenzyme Q10 in the cell, the fermenting level of the coenzyme Q10 is greatly promoted through the optimization to the concentration of the main substrate in the fermenting formula and through the optimization control to the stirring rotational speed during the fermenting process and can be improved to above 3000 u / ml, the determination of the optimal time for pot laying improves the utilization ratio of time of the production of the coenzyme Q10 in the cell, the fermentation cost is reduced, and the consumption of the fermenting raw material is greatly reduced.

Owner:YIDU HEC BIOCHEM PHARMA

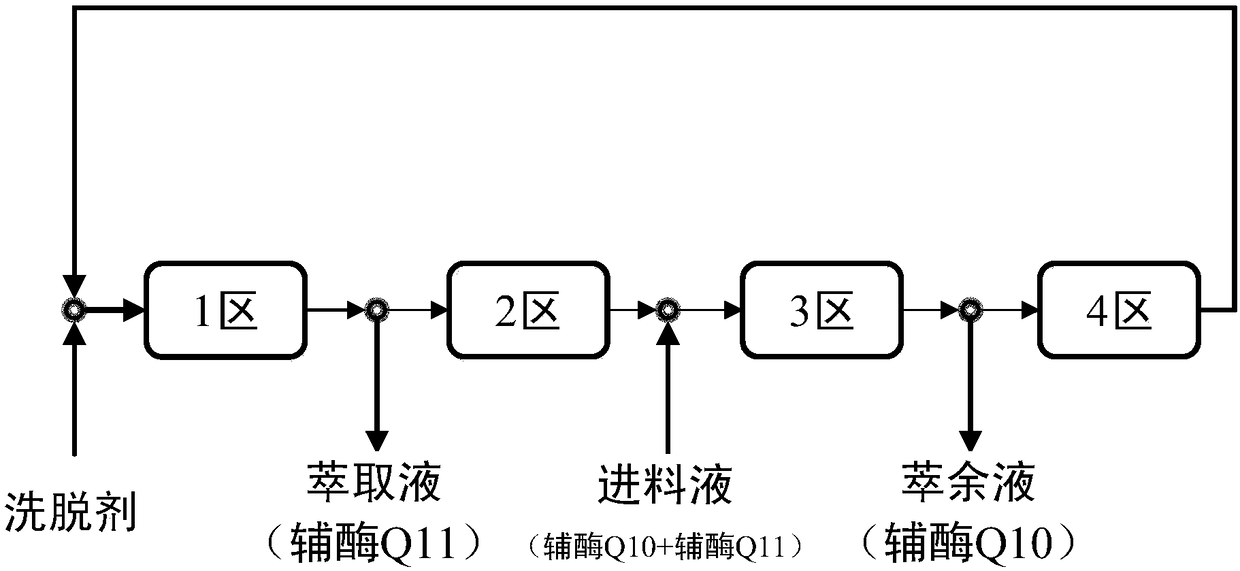

Method for separating coenzyme Q10 from coenzyme Q11 through simulated moving bed chromatography

ActiveCN108084007AHighly Selective Separation AbilityImprove separation efficiencyQuinone separation/purificationOrganic solventSimulated moving bed

The invention discloses a method for separating coenzyme Q10 from coenzyme Q11 through simulated moving bed chromatography. The method comprises the following steps: (1) dissolving a mixture of the coenzyme Q10 and the coenzyme Q11 in an organic solvent to prepare a feeding solution; (2) continuously introducing the feeding solution and eluent into a simulated moving bed chromatography system, continuously collecting an extraction solution rich in Q11 from an extraction hole of the simulated moving bed chromatography system, and continuously collecting raffinate liquid rich in Q10 from a raffinate hole; (3) performing post-treatment on the raffinate liquid to obtain a coenzyme Q10 monomer; performing post-treatment on the extraction solution to obtain a coenzyme Q11 monomer. The method disclosed by the invention has the advantages of simple preparation process, high degree of separation, large preparation amount, high recycling ratio, less solvent consumption and low production cost; moreover, the method is suitable for industrial production.

Owner:ZHEJIANG UNIV

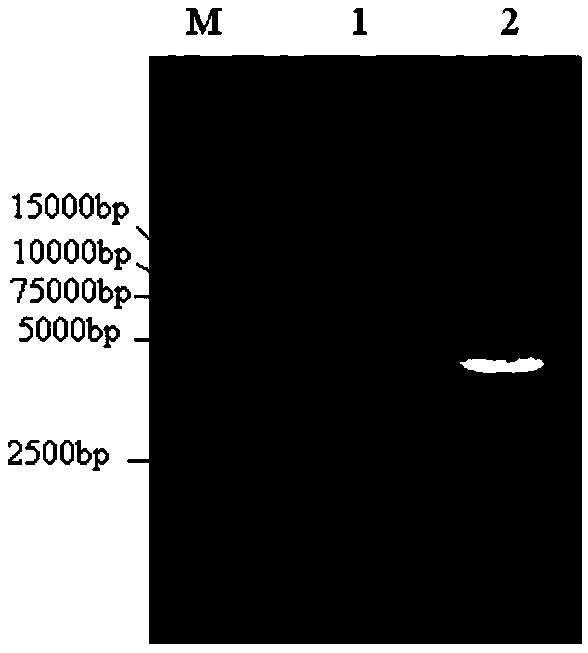

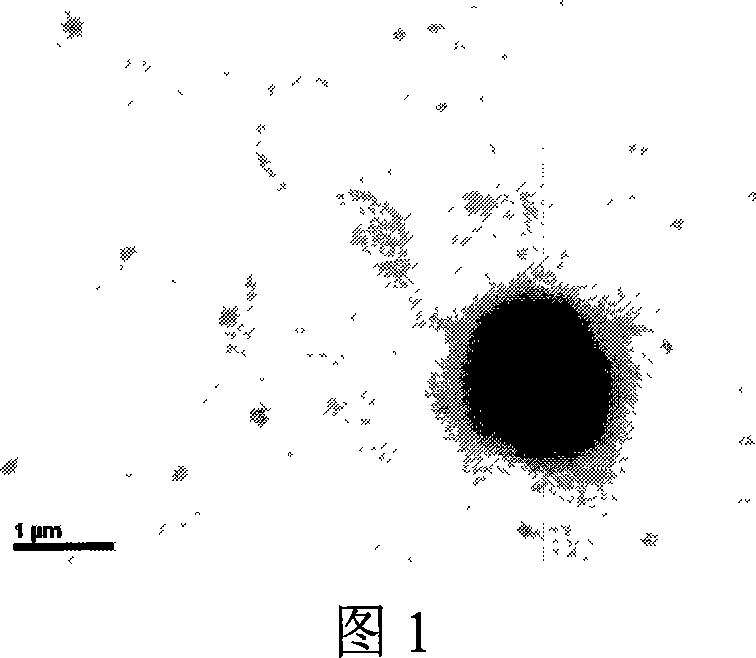

Novel strain sphingosine gingivalis ZUTE03 for producing coenzyme Q10 and uses thereof

InactiveCN101177670AHigh recovery rateReduce consumptionBacteriaFermentationSaponificationCo enzyme q10

The invention provides a new strain Sphingomonas sp.ZUTE03 that can produce coenzyme Q10 and is preserved in China Center for Type Culture Collection (CCTCC) on June 18, 2007, and the preservation number is CCTCC No. M207084. When the leavening of the invention is used for preparing the coenzyme Q10, a new technology of synchronization saponification extraction is adopted, which can save manpower, reagent and time with convenience and can improve the efficiency of the extraction technique for the coenzyme Q10 under the condition of nearly no damage of products.

Owner:ZHEJIANG UNIV OF TECH

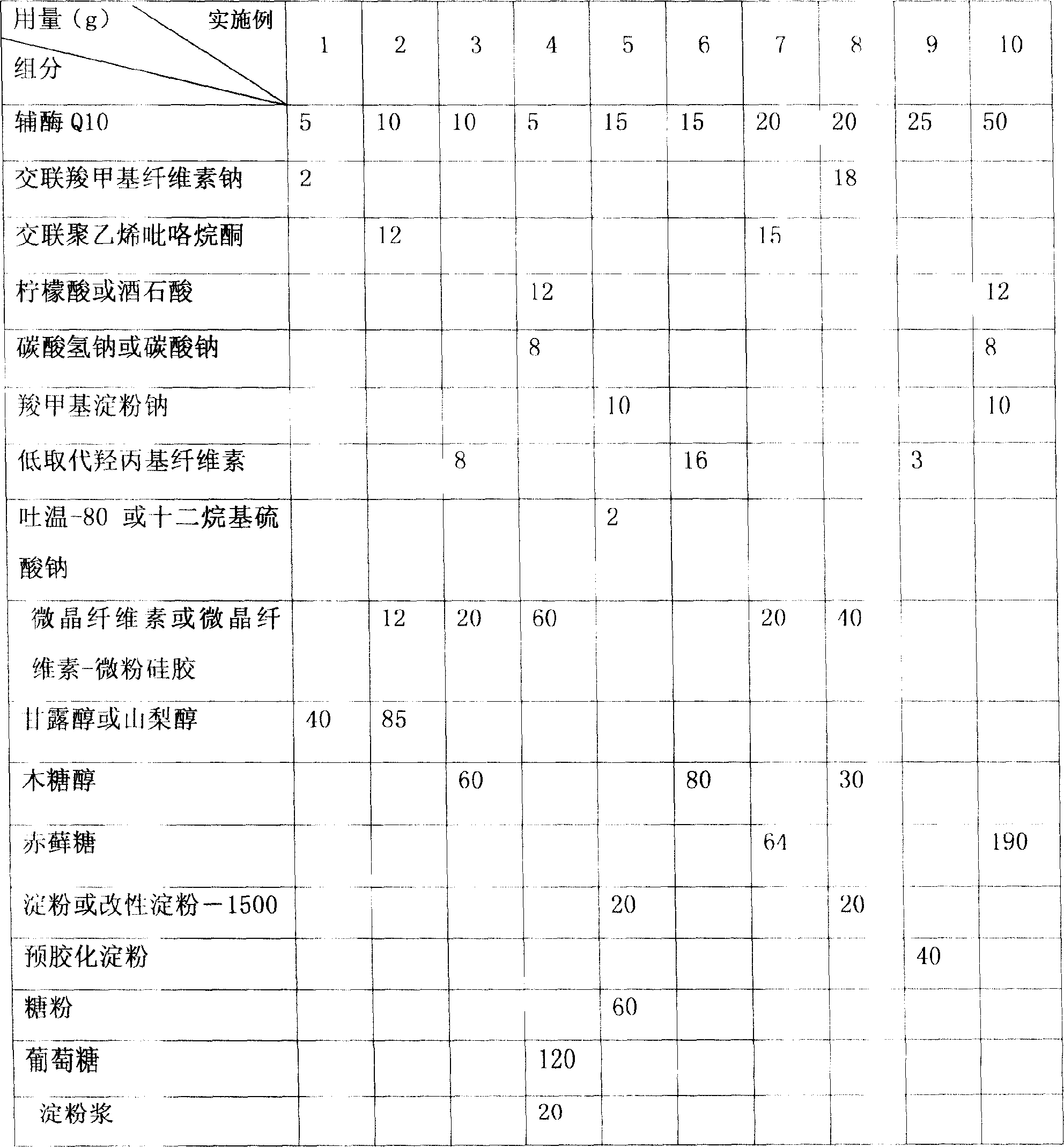

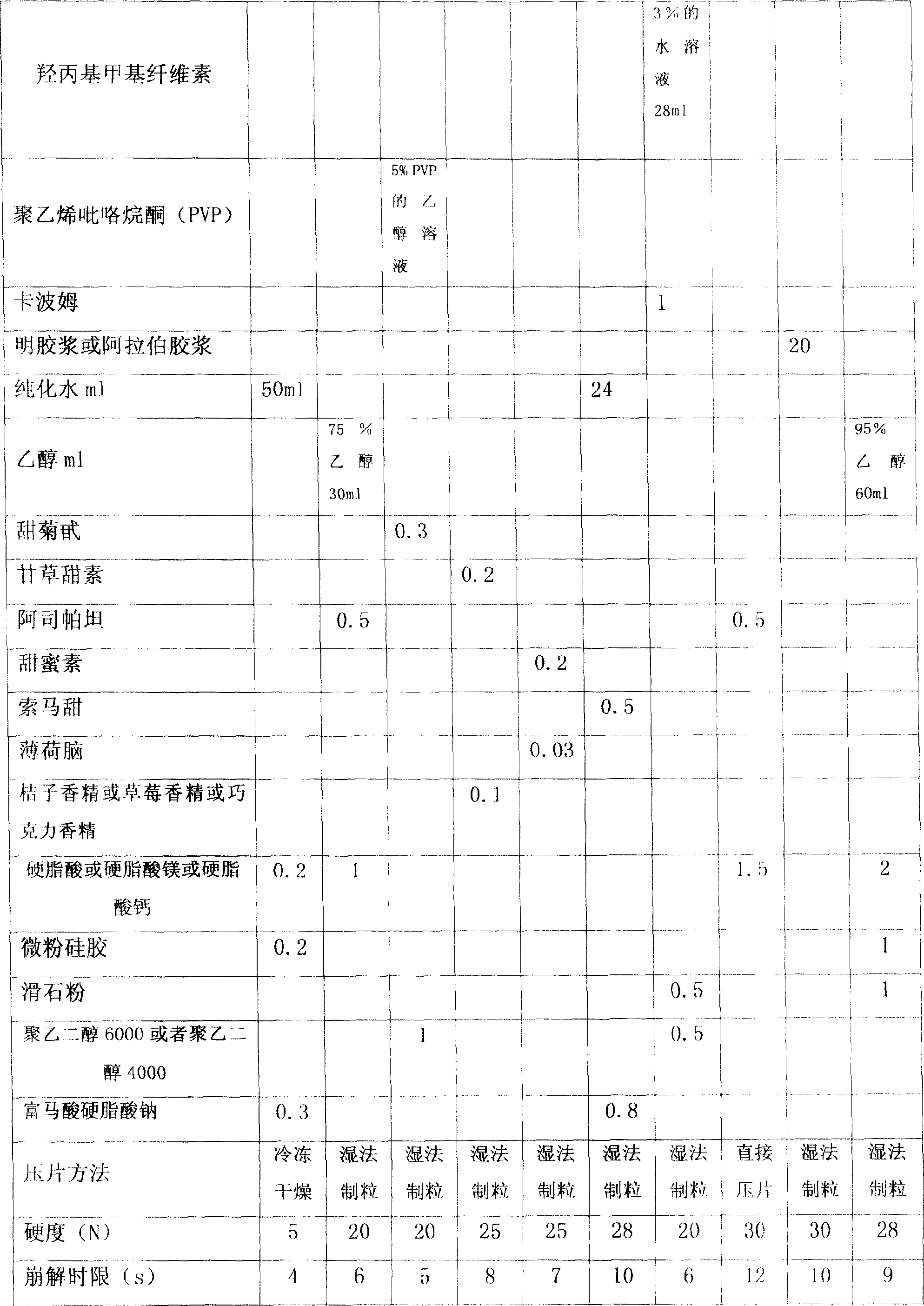

Orally disintegrating tablet of coenzyme Q10 and preparation method thereof

InactiveCN1961869ASuitable for consumptionNo grittinessOrganic active ingredientsDigestive systemFiller ExcipientMedicine

The invention discloses an orally disintegrating tablet of coenzyme Q10 comprising coenzyme Q10 as the main ingredient and auxiliary materials, wherein the weight proportions of the constituents include coenzyme Q10 5-50, crumbling agent 2-30, filling agent 40-200, flavoring agent 0-2, bonding agent 10-60, lubricating agent 0-5. The advantages of the tablet include shorter disintegration period, quick action, good taste, and fitting for mass production.

Owner:重庆市力扬医药开发有限公司

Method of producing reduced coenzyme Q10

Owner:KANEKA CORP

Composition containing reduced coenzyme q10, and method for stabilizing the composition

InactiveUS20100168249A1Suitable for oxidationReduced stabilityCosmetic preparationsBiocideWaxFatty acid

The invention provides a composition containing reduced coenzyme Q10, which is useful as a pharmaceutical product, food, cosmetic, animal drug, feed, and the like, as well as a stabilization method thereof. The oxidation of reduced coenzyme Q10 into oxidized coenzyme Q10 by molecular oxygen can be suppressed by setting, in a composition containing reduced coenzyme Q10 and at least one kind of oil component selected from the group consisting of fat, oil, a mixture thereof, fatty acid, wax and a surfactant, the weight ratio of the reduced coenzyme Q10 to the oil component to not less than 1 / 4 when the composition is a liquid, and not less than 1 / 9 when the composition is a solid.

Owner:KANEKA CORP

Coenzyme Q10 purifying process

InactiveCN1931819AEasy to recycleSimple processQuinone separation/purificationOrganic solventAntioxidant

The present invention provides one kind of simple and practical coenzyme Q10 purifying process suitable for industrial production. The process with crude coenzyme Q10 product with coenzyme Q10 content over 65 % as material includes dissolving in organic solvent, adding antioxidant and active carbon to decolorize, adding crystal seed to induce crystallization, filtering and washing, drying. The process can eliminate coenzyme Q7, Q8, Q9 and Q11 and coenzyme Q10 cis-isomer effectively and obtain coenzyme Q10 product with coenzyme Q10 content over 99.5 % and isomer content less than 0.5 %, and the product may be used in food, health product, beverage, cosmetics and medicine. The present invention has simple process, short production period, easy recovery and reuse of the solvent, high purifying efficiency and suitability for industrial production.

Owner:KUNMING TONGFA IND

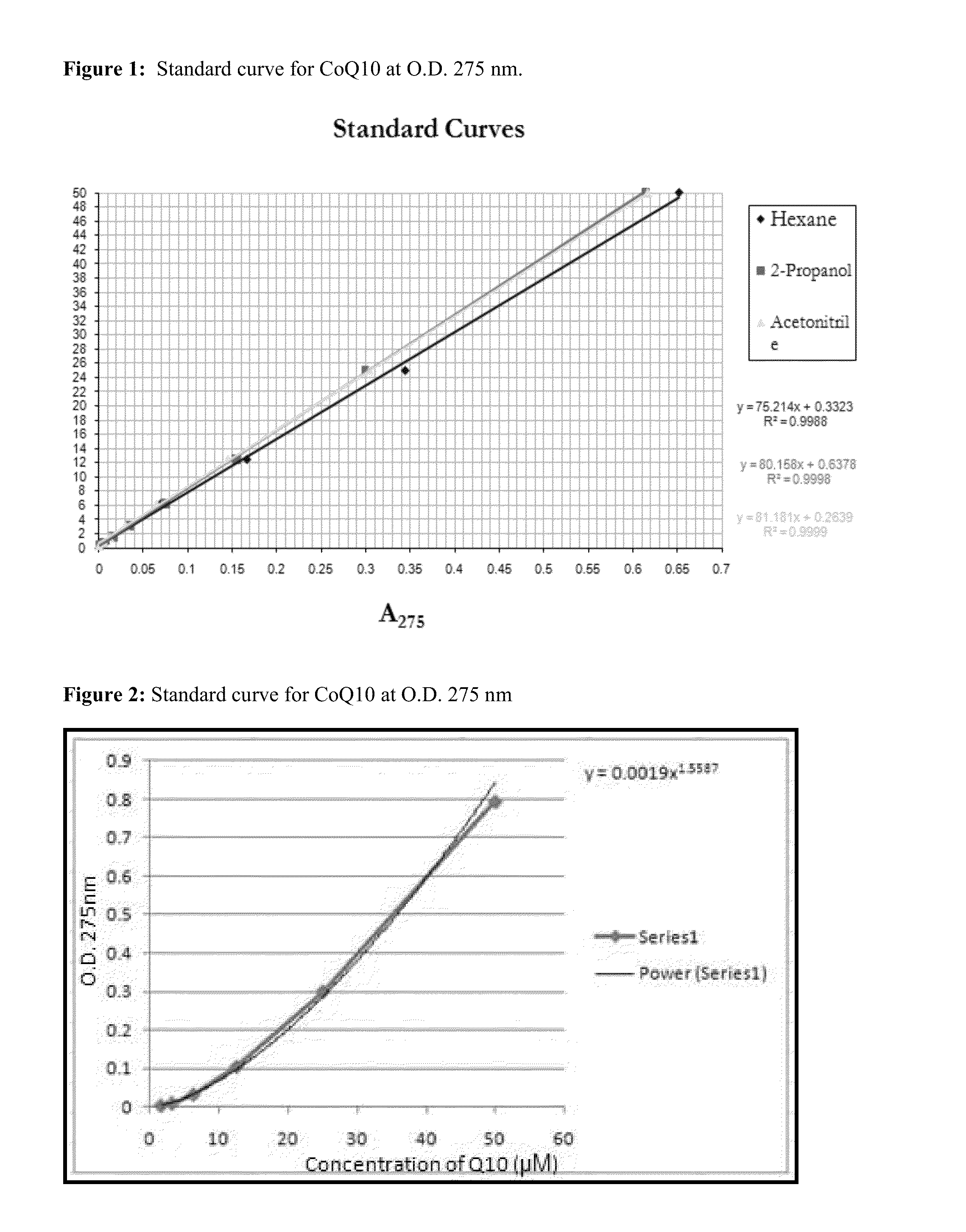

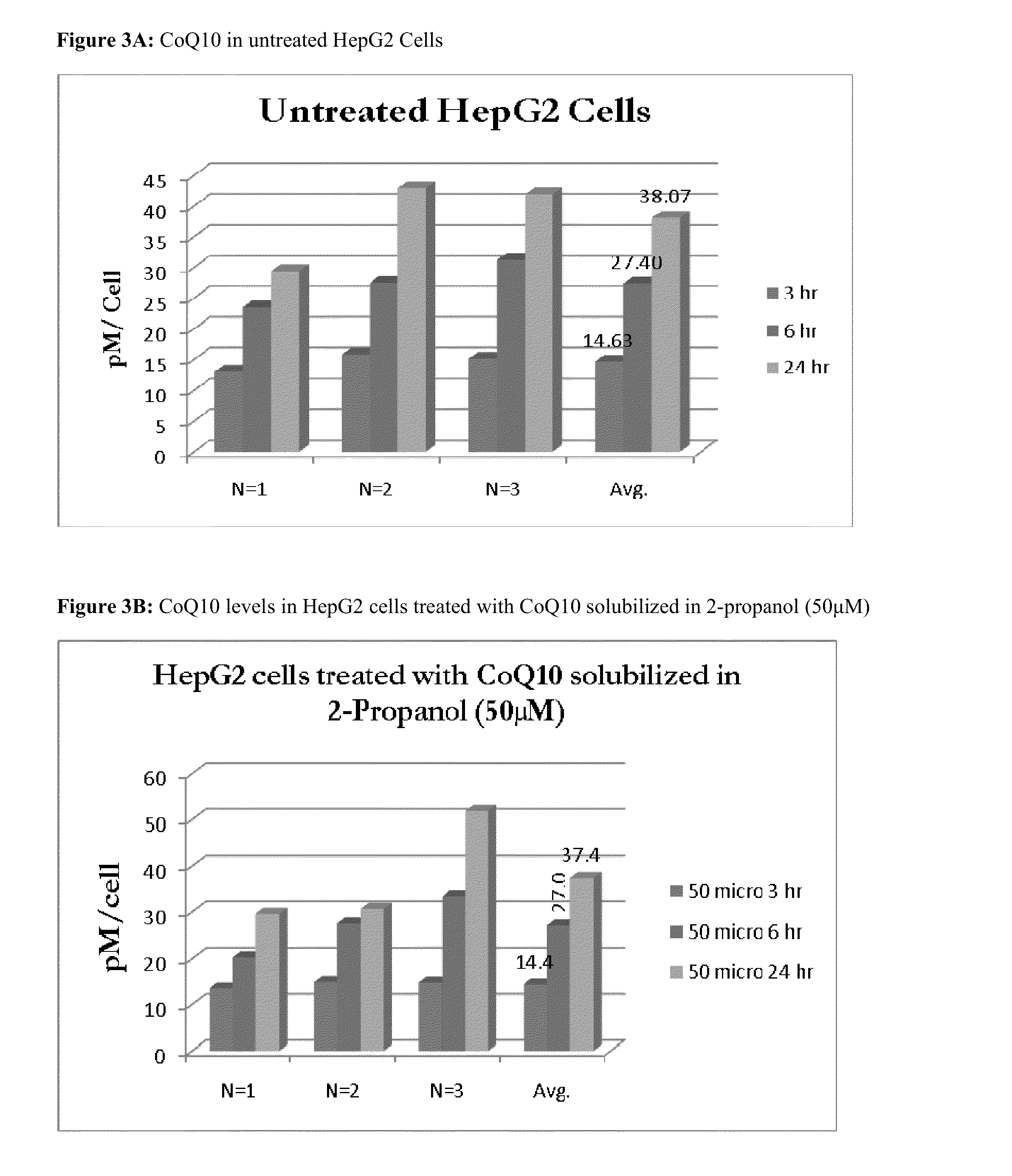

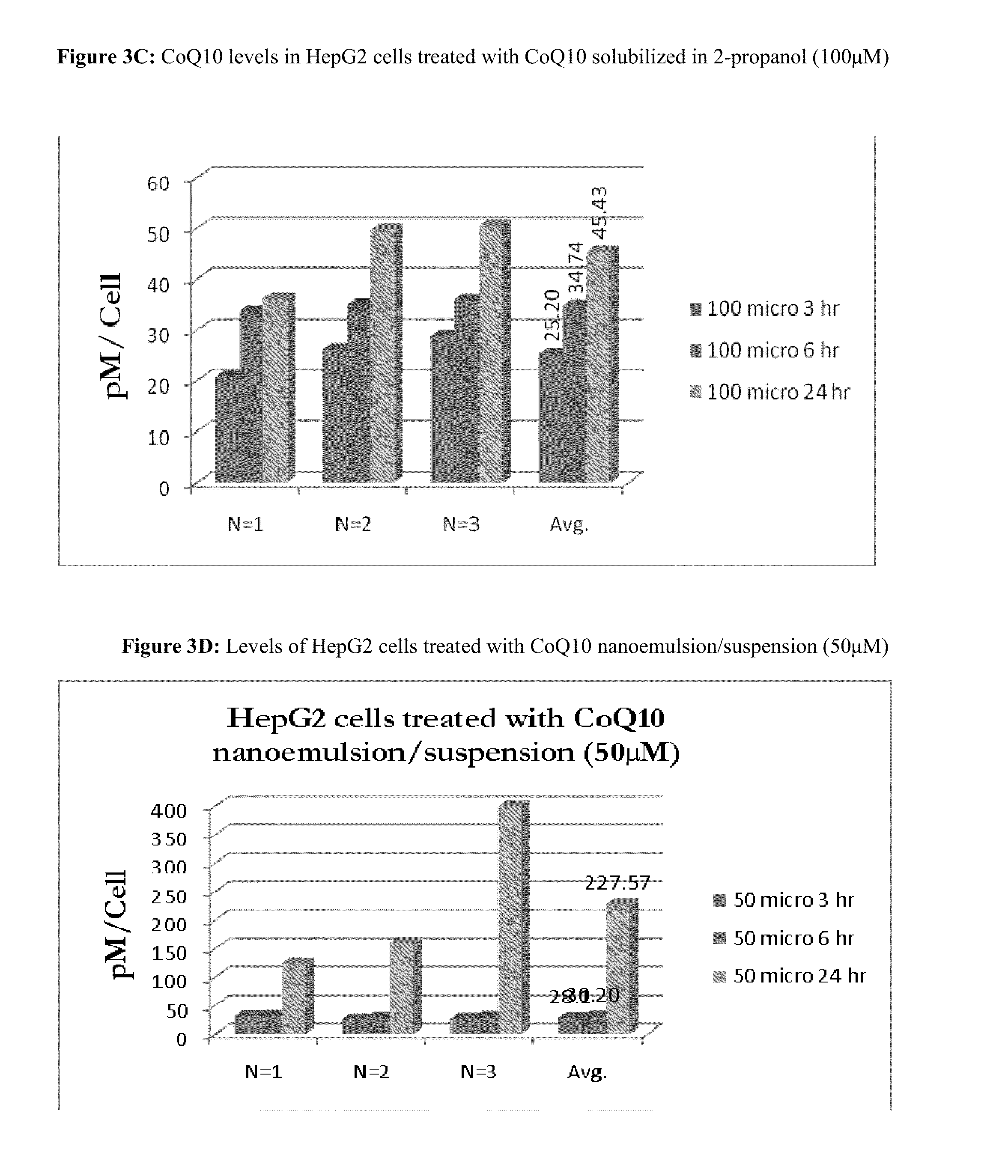

Methods and kits for detection of coenzyme q10

ActiveUS20140038302A1Speed up the extraction processShort amount of timeSamplingComponent separationHigh-Throughput Screening MethodsReagent

The invention provides methods for rapid and quantitative extraction and detection of coenzyme Q10 in a sample readily adaptable to high throughput screening methods. The invention further provides reagents and kits for practicing the methods of the invention.

Owner:BPGBIO INC

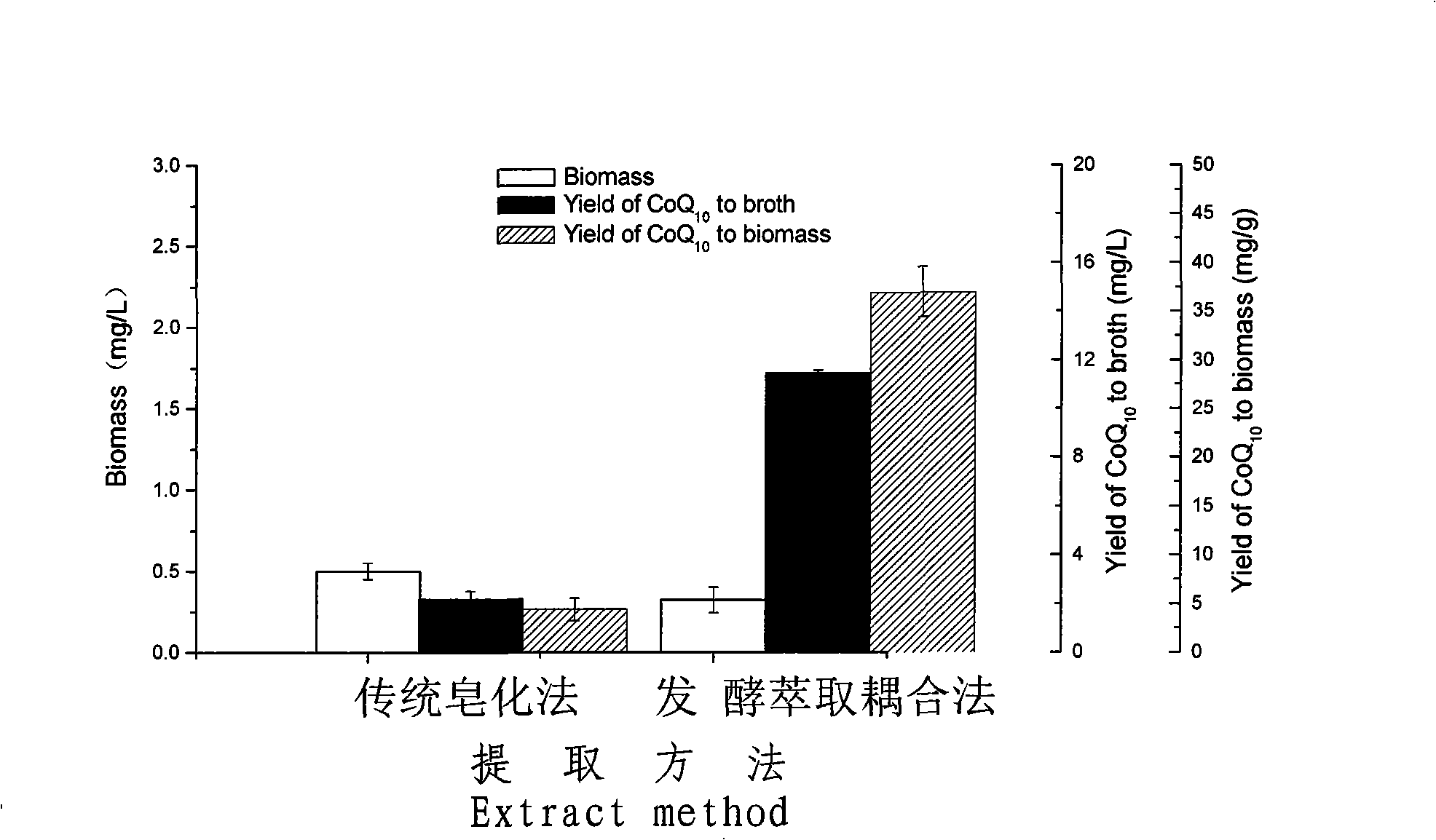

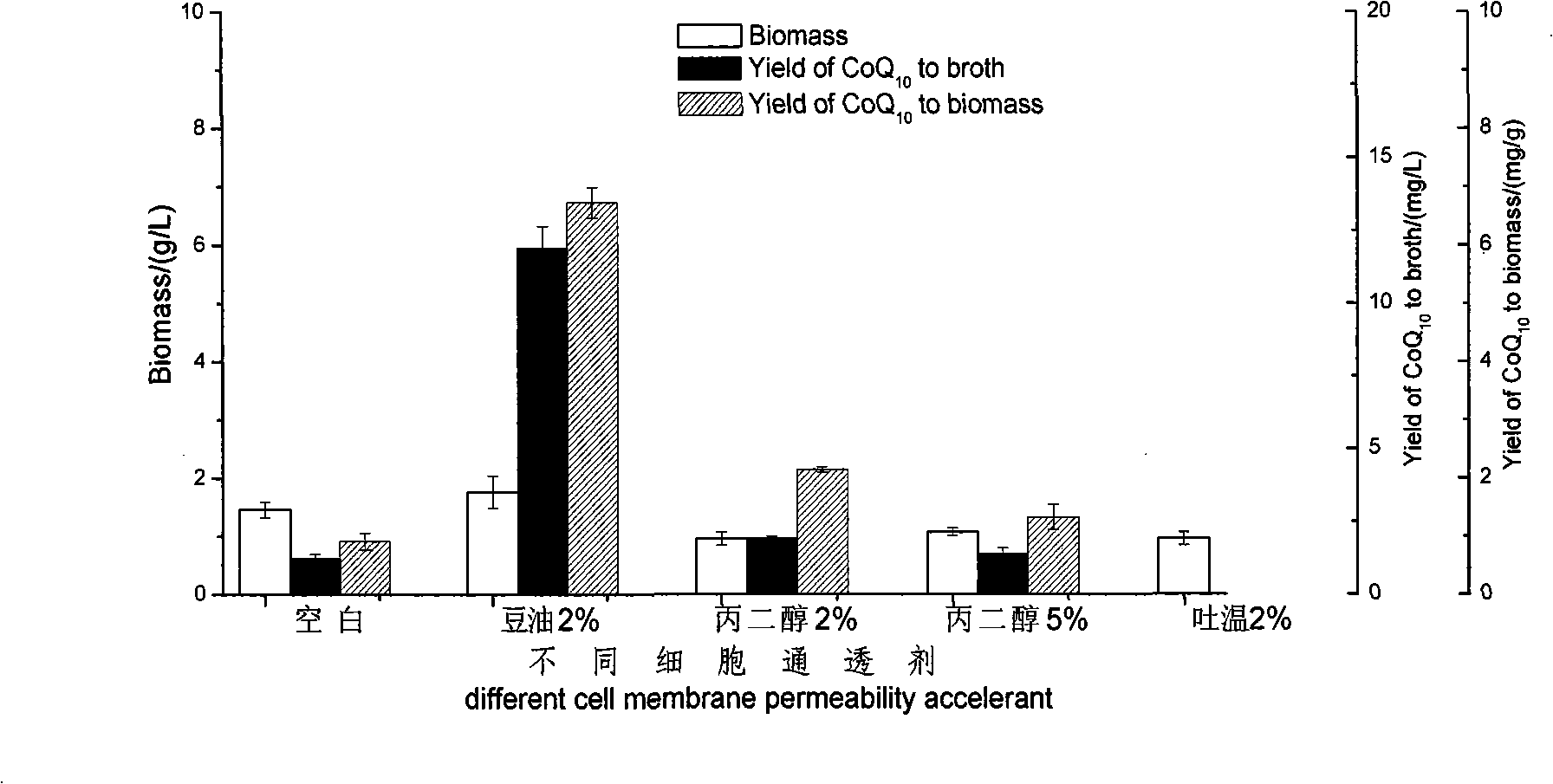

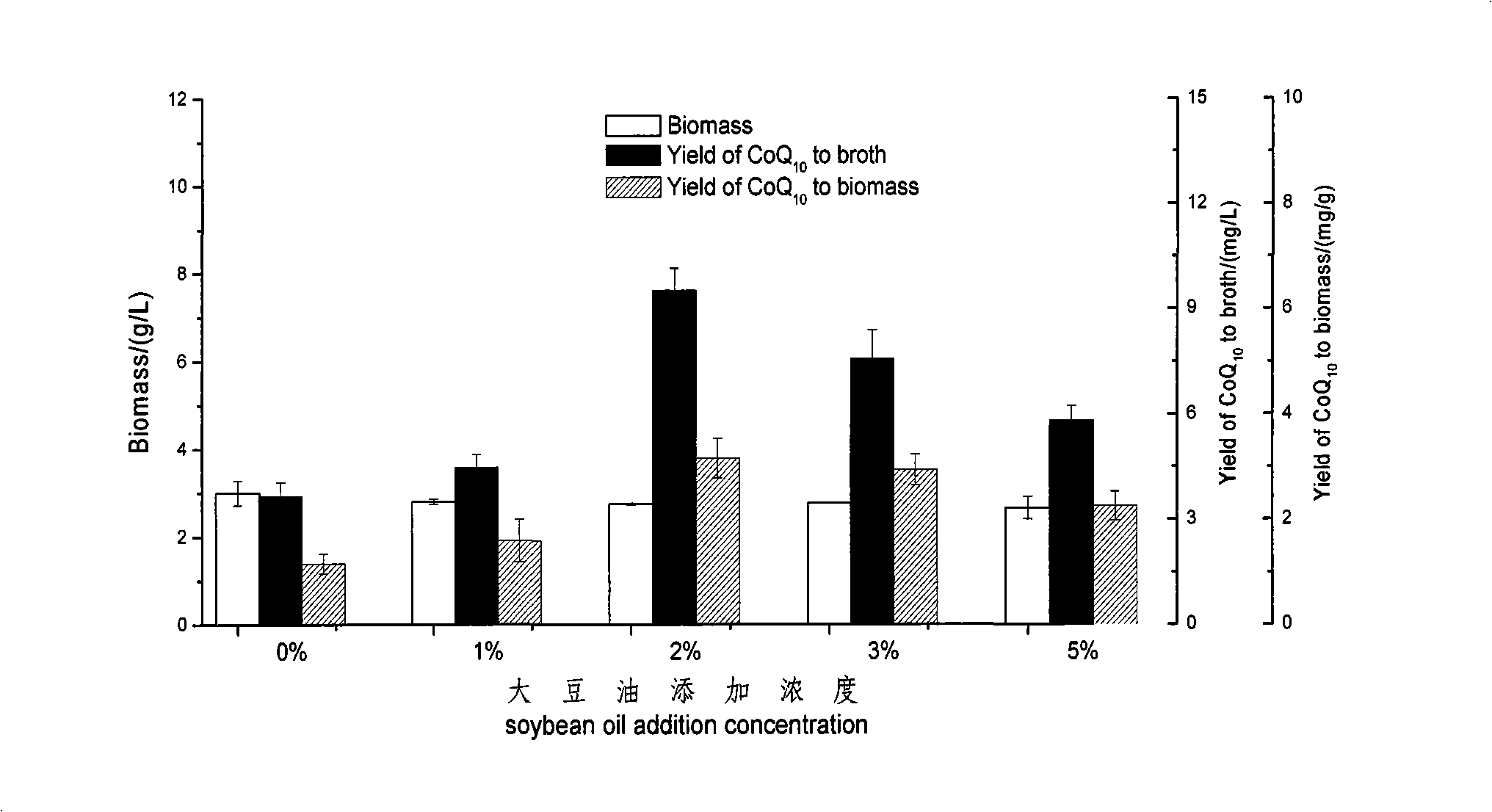

Process for preparing coenzyme Q10 by sphingosine unit cell strain fermentation, extraction and coupling

ActiveCN101307337AImprove extraction efficiencyHigh recovery rateMicroorganism based processesFermentationLiquid mediumOrganic layer

The invention provides a method for making coenzyme Q10 by means of sphingosine monad fermentation, extraction and coupling. The method comprises the following steps that: sphingosine monad strain is inoculated in liquid medium suitable for sphingosine strain; soybean oil with the volume occupying 1 to 5 percent of that of the liquid medium is added in the liquid medium so as to carry out cultivation at a temperature of between 25 and 28 DEG C for 24 to 36 hours; then, normal hexane with the volume occupying 20 to 50 percent of that of the liquid medium is added in the liquid medium so as to carry out cultivation at a temperature of between 25 and 28 DEG C for 6 to 12 hours; after the reaction is completed, the reaction liquid undergoes delamination and then the organic layer is taken out so as to obtain the coenzyme Q10 after separation and purification. The method has the advantages of high recovery rate of extraction solvent, economization on manpower and material resources, simple and time-saving method and high yield of coenzyme Q10, and is propitious to industrialized production.

Owner:ZHEJIANG UNIV OF TECH

Method of producing reduced coenzyme q10 as oily product

InactiveCN1762960AQuality improvementSave operating timeQuinone separation/purificationOrganic solventSlurry

The invention relates to a method for preparing reduced coenzyme Q10. Reduced coenzyme Q10 can be used as beneficial food, functional nutritional food, special health food, nutritional supplement, nutrient, beverage, feed, cosmetics, medicine, therapeutic drug, preventive The components of medicine etc., the method is suitable for high-quality and high-efficiency industrial production. High quality oily reduced coenzyme Q10 has low viscosity and is easy to handle, it is prepared by separating the aqueous phase from the reaction mixture obtained by the oily reaction of oxidized coenzyme Q10 and reducing agent in water, or by measuring the melting point or melting point of reduced coenzyme Q10 Concentrate the organic phase containing reduced coenzyme Q10 at the above temperature to remove the organic solvent coexisting therein. In addition, a solution or slurry of reduced coenzyme Q10 can be obtained by adding a desired solvent to the obtained oily product, or a solid reduced coenzyme Q10 can be prepared by adding seed crystals to the oily product.

Owner:KANEKA CORP

Compound health products containing coenzyme Q10 and spirulina

InactiveCN101331948ALessen liver damagePromote digestionFood preparationCancer preventionAdditive ingredient

The invention provides a medical health-care compound, using Q10 coenzyme as the main ingredient matched with spirulina and edible sugar-free additives. The medicine made by using such a compatibility can enhance the immunity, improve the ability of human body to resist tumor, virus and cancer, can exert the function of oxidation resistance, can prevent the pre-aging of skin and protect the cardio-cerebral vessels, can improve symptoms of asthma and allergy, can help cure intestinal and gastric ulcer, can promote the healing of the hurts, can enhance the physical ability, improve movement performance, relieve brain fatigue and improve the work and study efficiency. Compared with Q10 coenzyme with single ingredient or the spirulina, the medical health-care compound is tested by medical experiments to have cooperative functions in enhancing immunity and preventing chemical liver injury (including alcoholic liver injury, medical liver injury and fatty liver), and has better medical treatment and health-care effect.

Owner:YUNNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com