Method for separating coenzyme Q10 from coenzyme Q11 through simulated moving bed chromatography

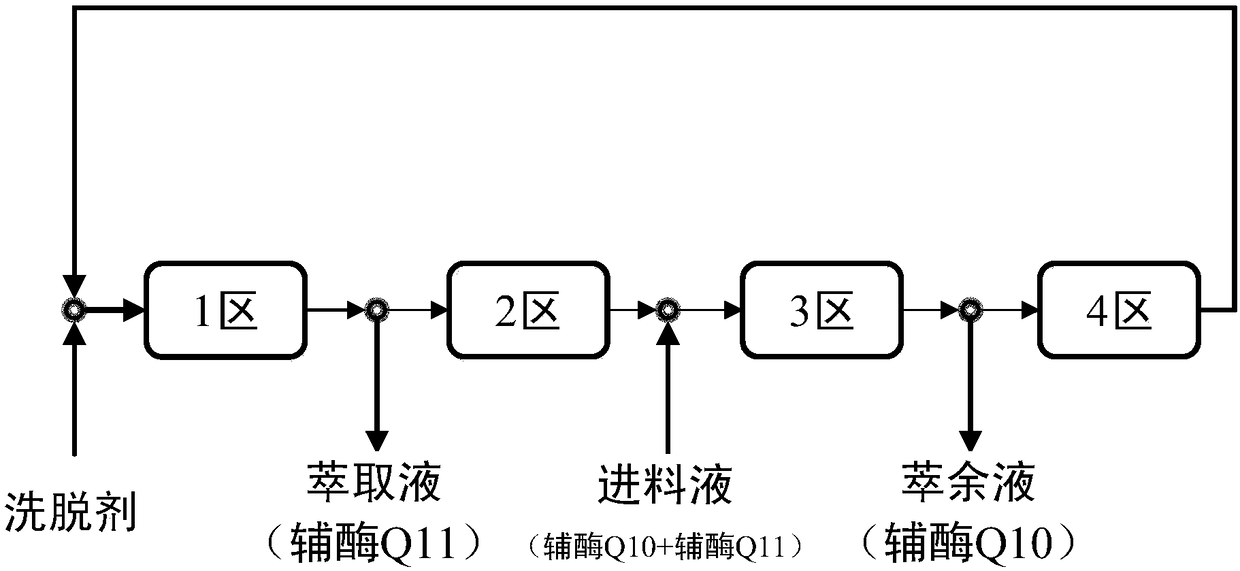

A technology for simulating moving bed and chromatographic separation, applied in the field of chemical separation, can solve the problems of low total recovery rate, weak separation capacity, long process route, etc., and achieve the effects of less solvent consumption, low production cost and high monomer purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The mixture of coenzyme Q10 and coenzyme Q11 (coenzyme Q11 / coenzyme Q10=13.6%, mass ratio), is completely dissolved with the mixture of ethanol and ethyl acetate (the percentage of ethanol accounting for the total volume is 70%), and the total concentration is 20g / L feed liquid.

[0041] The simulated moving bed is equipped with 8 chromatographic columns with a size of 1cm×15cm; the stationary phase is C18, its particle size is 10μm, and the pore size is 12nm; the eluent is the same as the solvent of the feed solution; the operating temperature is 20°C; the operating parameters are determined by optimization The flow rate of eluent is 6mL / min, the flow rate of feed liquid is 2mL / min, the flow rate of extract is 4mL / min, the flow rate of raffinate is 4.2mL / min, and the switching time is 3min. After 32 consecutive switchings, the system reaches equilibrium.

[0042] Collect a solution rich in coenzyme Q11 from the outlet of the extract, collect a solution rich in coenzy...

Embodiment 2

[0044] The mixture of coenzyme Q10 and coenzyme Q11 (coenzyme Q11 / coenzyme Q10=13.6%, mass ratio) is completely dissolved with the mixture of ethanol and ethyl acetate (the percentage of ethanol accounting for the total volume is 70%), and the total concentration is 50g / L feed liquid.

[0045] The simulated moving bed is equipped with 8 chromatographic columns with a size of 2cm×25cm; the stationary phase is C8, its particle size is 30μm, and the pore size is 12nm; the eluent is the same as the feed solution; the operating temperature is 20°C; the operating parameters are optimized and determined as follows: The flow rate of the eluent is 9mL / min, the flow rate of the feed liquid is 3mL / min, the flow rate of the extract is 7mL / min, the flow rate of the raffinate is 5mL / min, and the switching time is 8min. After 32 consecutive switchings, the system reaches equilibrium.

[0046] Collect a solution rich in coenzyme Q11 from the outlet of the extract, collect a solution rich in...

Embodiment 3

[0048] The mixture of coenzyme Q10 and coenzyme Q11 (coenzyme Q11 / coenzyme Q10=9.48%, mass ratio), is completely dissolved with the mixture of ethanol and tetrahydrofuran (the percentage of ethanol accounting for the total volume is 80%), and the total concentration is 20g / L Feed liquid.

[0049] The simulated moving bed is equipped with 16 chromatographic columns with a size of 1cm×15cm; the stationary phase is AMBERCHROM CG300 polystyrene resin with a particle size of 35μm and a pore size of 15nm; the eluent is the same as the feed solution; the operating temperature is 40°C; the operating parameters After optimization, the flow rate of the eluent is 16mL / min, the flow rate of the feed liquid is 2mL / min, the flow rate of the extract is 9.5mL / min, the flow rate of the raffinate is 8.5mL / min, and the switching time is 5min. After 48 consecutive switchings, the system reaches equilibrium.

[0050] Collect a solution rich in coenzyme Q11 from the outlet of the extract, collect ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com