A kind of preparation method of lead ion imprinted composite hollow microsphere

A lead ion, hollow technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems of unfavorable adsorption capacity, small specific surface area, lack of adsorption, etc., to achieve improved stability, large specific surface area, The effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

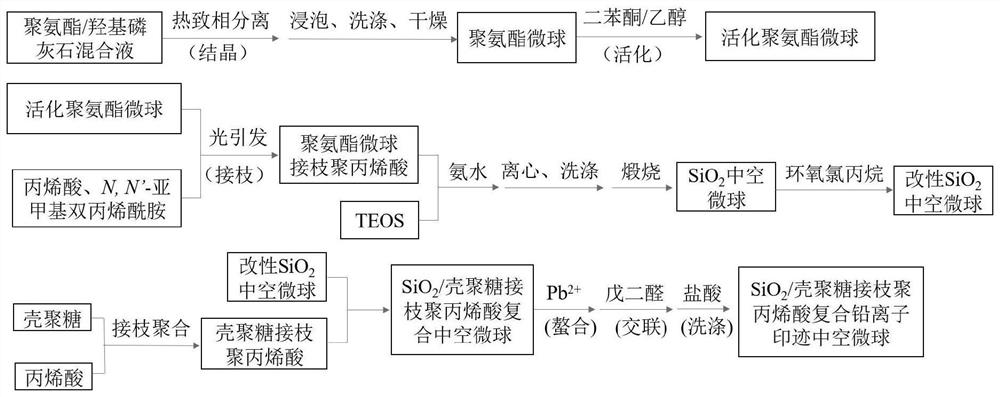

Method used

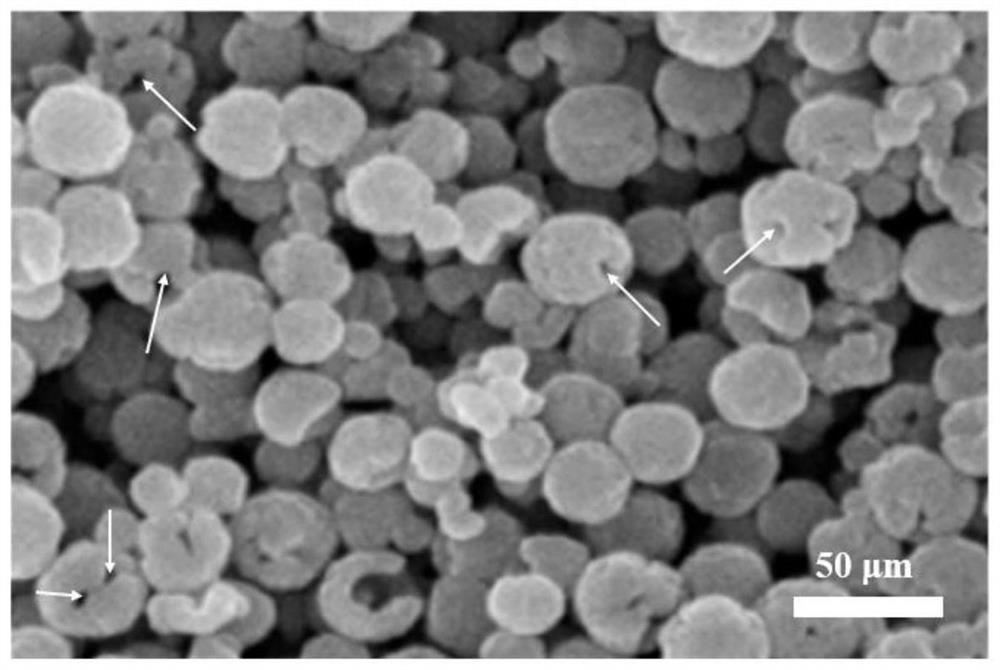

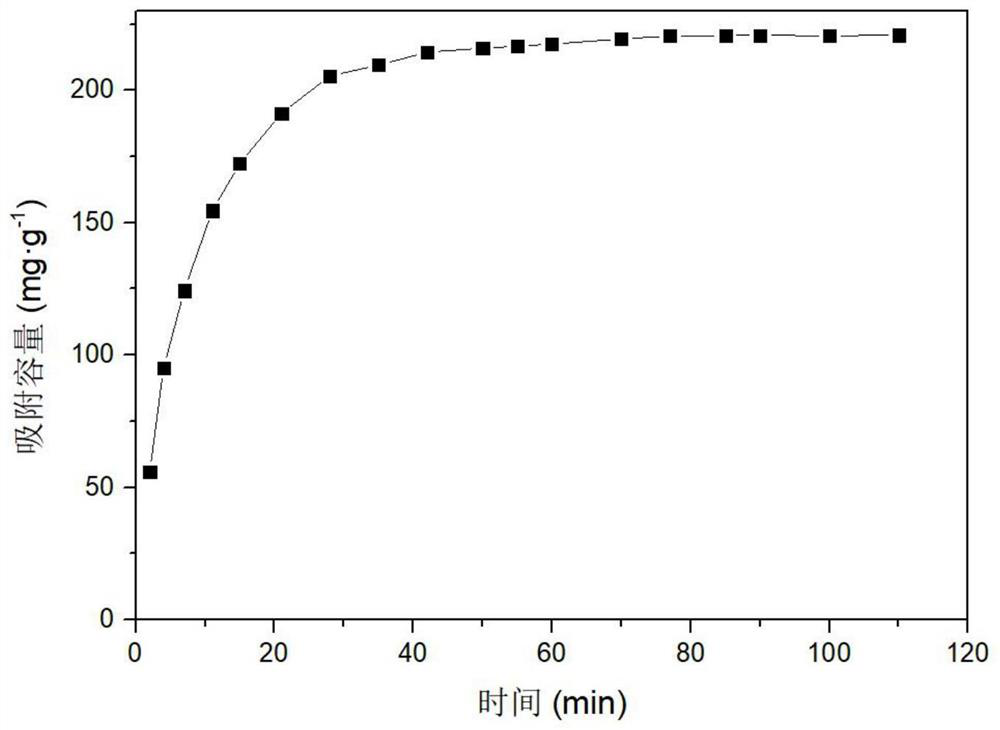

Image

Examples

Embodiment 1

[0045] 1) Add 1.5g polyurethane to a mixed solvent of 2g N,N-dimethylformamide and 14g tetrahydrofuran, stir and dissolve at 50°C, then add 0.001g nano-hydroxyapatite, and mix to obtain a mixed solution; mix the mixed solution Freeze in a -40°C low-temperature refrigerator for 2 hours. After freezing, put the mixed solution into 200 mL of ice-water mixed solution, remove the mixed solvent, and dry to obtain polyurethane microspheres;

[0046] 2) Soak the polyurethane microspheres in a mixed solution of 4g benzophenone and 96g ethanol, and set aside after activation; dissolve 1g acrylic acid, 0.01g N,N'-methylenebisacrylamide and 0.01g ammonium persulfate in 100mL distilled water 0.6 g of polyurethane microspheres activated by benzophenone were added, and graft polymerization was carried out by ultraviolet light irradiation under a nitrogen atmosphere. The intensity of ultraviolet light was 500 W, and the irradiation time was 20 minutes to obtain polyacrylic acid grafted with po...

Embodiment 2

[0054] 1) Add 1.8g of polyurethane to a mixed solvent of 1g N,N-dimethylformamide and 15g of tetrahydrofuran, and dissolve with magnetic stirring at 50°C, then add 0.002g of nano-hydroxyapatite, and mix well to obtain a mixed solution; the mixed solution Freeze in a low-temperature refrigerator at -30°C for 3 hours. After freezing, put the mixture into 200 mL of ice-water mixture, remove the mixed solvent, and dry to obtain polyurethane microspheres;

[0055] 2) Soak the polyurethane microspheres in a mixed solution of 4g benzophenone and 96g ethanol, and set aside after activation; Add 0.8 g of benzophenone-activated polyurethane microspheres to distilled water, and carry out graft polymerization by ultraviolet light irradiation under a nitrogen atmosphere. The ultraviolet light intensity is 500 W, and the irradiation time is 20 minutes to obtain polyacrylic acid grafted with polyurethane microspheres.

[0056] 3) Add 0.6 g of polyurethane microspheres grafted with polyacryli...

Embodiment 3

[0063] 1) Add 1.5g of polyurethane to a mixed solvent of 1g N,N-dimethylformamide and 12g of tetrahydrofuran, stir and dissolve at 50°C, then add 0.015g of nano-hydroxyapatite, and mix well to obtain a mixed solution; Freeze in a low-temperature refrigerator at -25°C for 3 hours. After freezing, put the mixed solution into 200 mL of ice-water mixed solution, remove the mixed solvent, and dry to obtain polyurethane microspheres;

[0064] 2) Soak the polyurethane microspheres in a mixed solution of 4g benzophenone and 96g ethanol, and set aside after activation; Add 0.8 g of benzophenone-activated polyurethane microspheres to distilled water, and carry out graft polymerization by ultraviolet light irradiation under a nitrogen atmosphere. The ultraviolet light intensity is 500 W, and the irradiation time is 20 minutes to obtain polyacrylic acid grafted with polyurethane microspheres.

[0065] 3) Add 0.5 g of polyurethane microspheres grafted with polyacrylic acid, 0.002 g of cety...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com