A kind of preparation method of copper ion imprinted nanofiber membrane

A technology of nanofiber membranes and copper ions, applied in fiber treatment, fiber types, chemical instruments and methods, etc., can solve the problems of poor stability of loaded liquid membranes, limited applications, and unsatisfactory link energy selectivity, etc., to achieve increased Effects of specific surface area and porosity, volume reduction, and ease of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

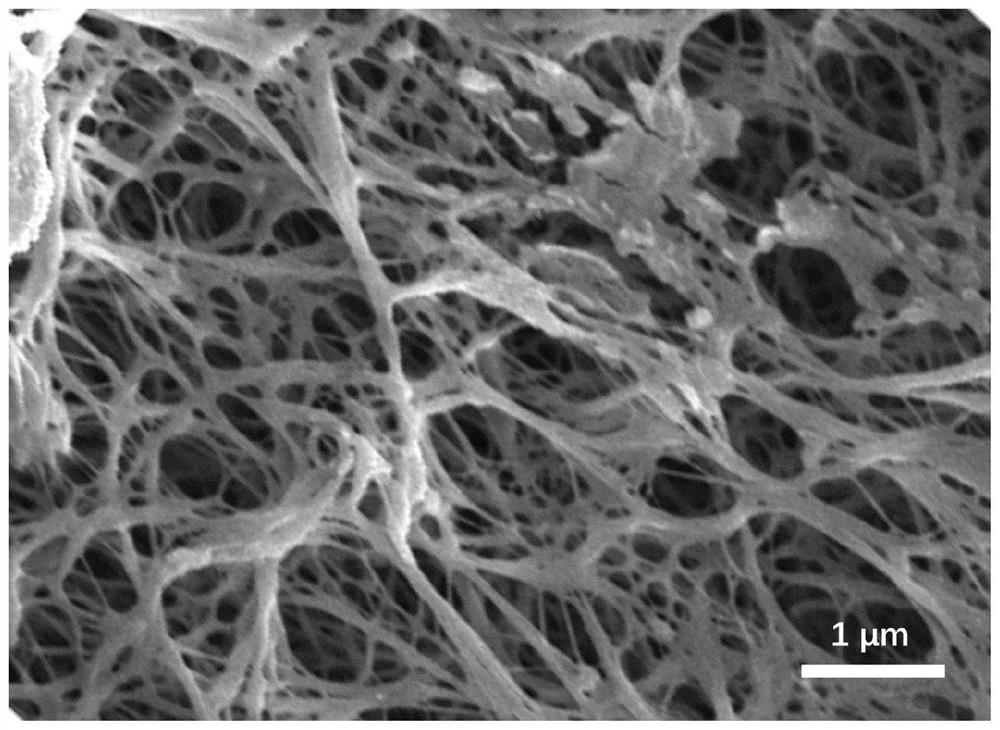

[0037] 1) Add 1.0 g of polystyrene into a mixed solvent of 20 g of N,N-dimethylformamide and 10 g of N-methylpyrrolidone, and magnetically stir for 6 hours at room temperature to fully dissolve it to obtain a solution. Pour the solution into a petri dish, put it into a low-temperature refrigerator at -30°C for 60 minutes (thermally induced phase separation), quickly take out the petri dish after freezing, put it into 500 mL of methanol (non-solvent induced phase separation), and remove N , N-dimethylformamide and N-methylpyrrolidone solvent, change methanol once every 6h, change 4 times, and finally freeze-dry the sample to obtain polystyrene nanofiber membrane.

[0038] 2) Soak the polystyrene nanofiber membrane in a solution of 4 g of benzophenone and 96 g of ethanol, take it out after 10 min, and dry it in vacuum to obtain an activated polystyrene nanofiber membrane for future use.

[0039] 3) Dissolve 1.88g of copper nitrate in a mixed solution of 0.72g of acrylic acid and...

Embodiment 2

[0044] 1) Add 1.0 g of polystyrene into a mixed solvent of 12.5 g of N,N-dimethylformamide and 7 g of N-methylpyrrolidone, and stir magnetically at room temperature for 6 hours to fully dissolve it to obtain a solution. Pour the solution into a petri dish, put it into a low-temperature refrigerator at -20°C for 80 minutes (thermally induced phase separation), quickly take out the petri dish after freezing, put it into 500 mL of methanol (non-solvent phase separation), remove N, The N-dimethylformamide and N-methylpyrrolidone solvents were changed to methanol once every 6 hours, and changed 4 times, and finally the samples were freeze-dried to obtain polystyrene nanofiber membranes.

[0045] 2) Soak the polystyrene nanofiber membrane in a solution of 5 g of benzophenone and 95 g of ethanol, take it out after 10 minutes, and dry it in vacuum to obtain an activated polystyrene nanofiber membrane for future use.

[0046] 3) Dissolve 1.88g of copper nitrate in a mixed solution of 1...

Embodiment 3

[0049] 1) Add 1.0 g of polystyrene into a mixed solvent of 11 g of N,N-dimethylformamide and 8 g of N-methylpyrrolidone, and magnetically stir for 6 hours at room temperature to fully dissolve it to obtain a solution. Pour the solution into a petri dish, put it in a low-temperature refrigerator at -20°C for 60 minutes (thermally induced phase separation), quickly take out the petri dish after freezing, put it in 500 mL of methanol (non-solvent phase separation), remove N, The N-dimethylformamide and N-methylpyrrolidone solvents were changed to methanol once every 6 hours, and changed 4 times, and finally the samples were freeze-dried to obtain polystyrene nanofiber membranes.

[0050] 2) Soak the polystyrene nanofiber membrane in a solution of 6 g of benzophenone and 96 g of ethanol, take it out after 10 minutes, and dry it in vacuum to obtain an activated polystyrene nanofiber membrane for future use.

[0051] 3) Dissolve 1.88g of copper nitrate in a mixed solution of 0.94g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com