A method for separating and purifying phosphatidylcholine by polyionic liquid extraction

A technology of polyionic liquid and phosphatidylcholine is applied in the field of chemical engineering to achieve the effects of high yield, good biocompatibility and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

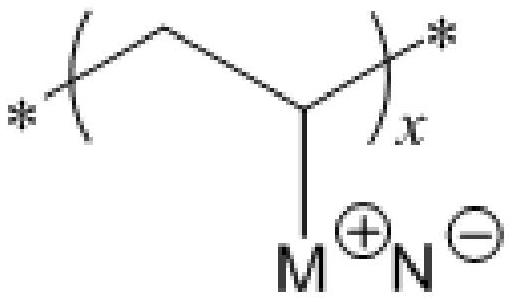

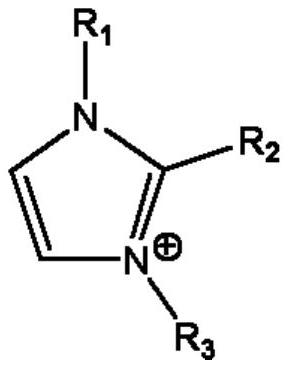

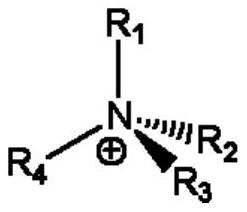

Method used

Image

Examples

Embodiment 1

[0056] Commercially available soybean phospholipid mixture (the weight percentage of phosphatidylcholine: 28%) and normal hexane to make phospholipid mixture concentration is the stock solution of 260 g / liter, with poly(1-vinyl-3-ethylimidazole The ethanol solution of bromide) is the extractant (the weight percentage of poly(1-vinyl-3-butylimidazolium bromide): 12%), with n-hexane as the washing agent, at 30°C, in the fractionation extraction device Fractional distillation extraction was carried out, and the extract was collected. The extract is back-extracted with n-hexane, and the n-hexane solution is vacuum-concentrated to remove the organic solvent and dried to obtain the phosphatidylcholine product. Through HPLC analysis, the absolute purity of phosphatidylcholine in the final product was 76.2%, and the yield was 91.8%.

Embodiment 2

[0058] Commercially available soybean phospholipid mixture (the weight percentage of phosphatidylcholine: 28%) and n-heptane are made into the raw material solution that phospholipid mixture concentration is 200 g / liter, and poly(1-vinyl-3-octyl The methanol solution of imidazolium chloride salt) is the extractant (the weight percentage of poly(1-vinyl-3-octyl imidazolium chloride salt): 20%), with n-heptane as the washing agent, at 25°C, in fractional distillation Fractional extraction is carried out in the extraction device, and the extract is collected. The extract is back-extracted with n-heptane, and the n-heptane solution is vacuum-concentrated to remove the organic solvent and dried to obtain the phosphatidylcholine product. Through HPLC analysis, the absolute purity of phosphatidylcholine in the final product was 81.2%, and the yield was 95.8%.

Embodiment 3

[0060] Commercially available soybean phospholipid mixture (weight percentage of phosphatidylcholine: 42%) and petroleum ether with a boiling range of 90 to 120° C. are made into a raw material solution with a concentration of phospholipid mixture of 280 grams per liter, and poly(vinyl tri The methanol solution of butylammonium acetate) is the extractant (the weight percentage of poly(vinyl tributylammonium acetate): 25%), and the sherwood oil with the boiling range of 90~120°C is the washing agent. At 30°C, perform fractional distillation extraction in a fractional distillation extraction device, and collect the extract. The extract is concentrated by evaporation, back-extracted with petroleum ether, the petroleum ether solution is concentrated in vacuum to remove the organic solvent, washed with water, and dried to obtain the phosphatidylcholine product. Through HPLC analysis, the absolute purity of phosphatidylcholine in the final product was 89.1%, and the yield was 92.0%....

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com