Soft capsule containing coenzyme Q10 and preparation method and application thereof

A soft capsule and coenzyme technology, applied in the field of new anti-tumor indications of chemical class I new drugs, can solve the problems of lack of controlled trials, insufficient number of cases and treatment plan design, and inability to show effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

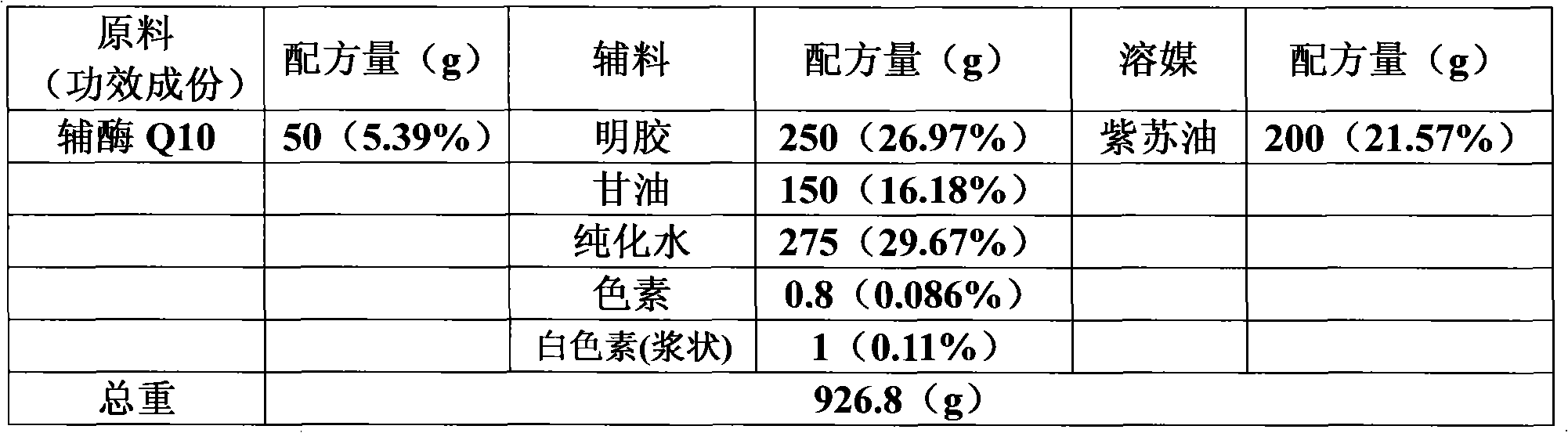

[0022] Recipe: (wherein percentage composition is percentage by weight)

[0023]

[0024] Preparation: prepare 250g of gelatin, 150g of glycerin, 275g of purified water, 0.8g of pigment, and 1g of white pigment (slurry) according to the gelation process (heating, dissolution, vacuum defoaming, standing, and heat preservation) for use. Ingredients Coenzyme Q1050g, perilla oil 200g are prepared according to the content preparation process (weighing, feeding, heating, dissolving). The prepared contents and the gelatinized gelatin were made into pills by the rolling mode "Yixingrui" brand soft capsule capsule process, and the coenzyme Q10 "Yixingrui" brand soft capsules were obtained after shaping, washing, drying, picking and testing. Capsules, specifications: 0.25g per capsule, 60 capsules per bottle (theoretical granulation is 1000 capsules).

Embodiment 2

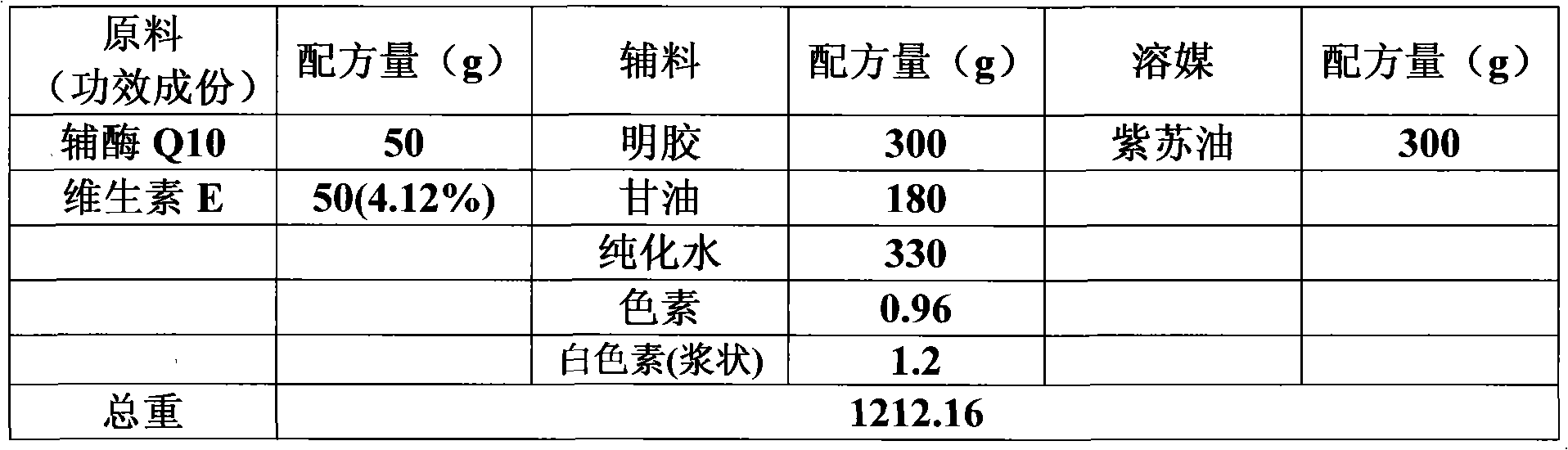

[0026] formula:

[0027]

[0028] preparation:

[0029]Prepare 300g of gelatin, 180g of glycerin, 330g of purified water, 0.96g of pigment, and 1.2g of white pigment (slurry) according to the gelatinization process (heating, dissolution, vacuum defoaming, standing, and heat preservation) for use as auxiliary materials. 1050g of coenzyme Q, 50g of vitamin E, and 300g of perilla oil are prepared according to the content preparation process (weighing, feeding, heating, dissolving). The prepared contents and the gelatinized gelatin were made into pills by the rolling mode "Yixingrui" brand soft capsule capsule process, and the coenzyme Q10 "Yixingrui" brand soft capsules were obtained after shaping, washing, drying, picking and testing. Capsules, specifications: 0.4g per capsule, 60 capsules per bottle (theoretical granulation is 1000 capsules).

Embodiment 3

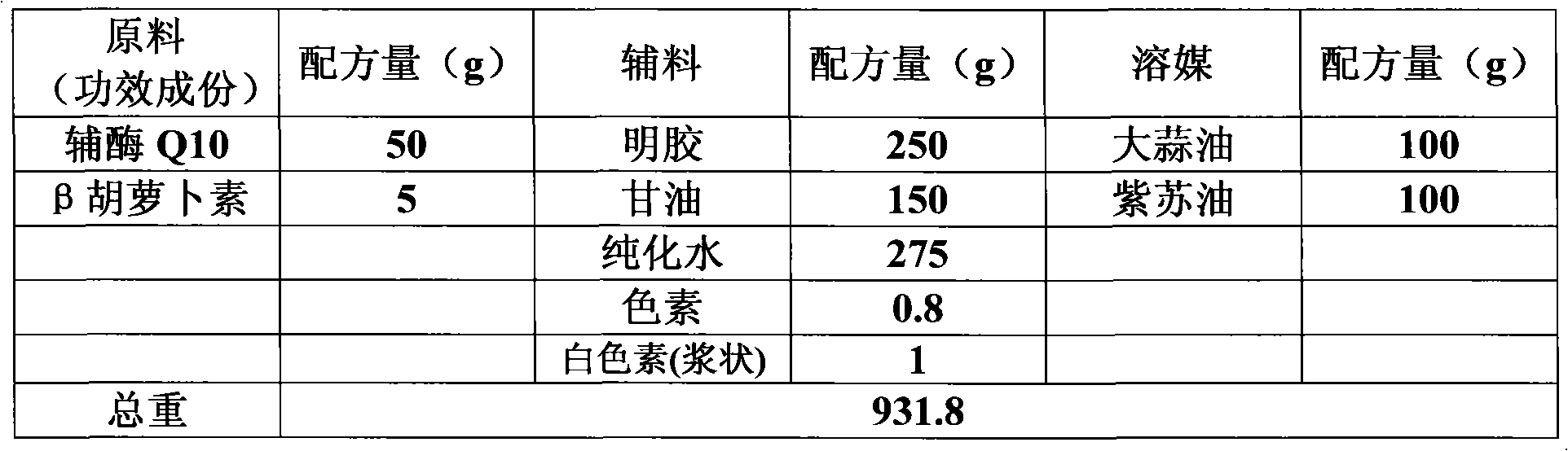

[0031] formula:

[0032]

[0033] preparation:

[0034] Prepare 250g of gelatin, 150g of glycerin, 275g of purified water, 0.8g of pigment, and 1g of white pigment (slurry) according to the gelatinization process (heating, dissolution, vacuum defoaming, standing, and heat preservation) as auxiliary materials, and the functional ingredient coenzyme Q1050g, β-carotene 5g, garlic oil 100g, perilla oil 100g, prepared according to the content preparation process (weighing, feeding, heating, dissolving). The preparation contents and the gelatinized liquid are made into pills by the rolling mode soft capsule capsule process, and the coenzyme Q10 "Yixingrui" brand soft capsules are obtained after finalizing, washing the pills, drying, picking up the pills, and testing, specifications: per capsule 0.255g, 60 capsules per bottle (theoretical granulation is 1000 capsules).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com