Superconductive medium radiator

A superconducting medium and heat sink technology, applied in heat exchange equipment, heat exchange materials, chemical instruments and methods, etc., can solve the problems of high chemical activity and high corrosion of sodium peroxide, achieve good chemical stability, Good corrosion resistance and small temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

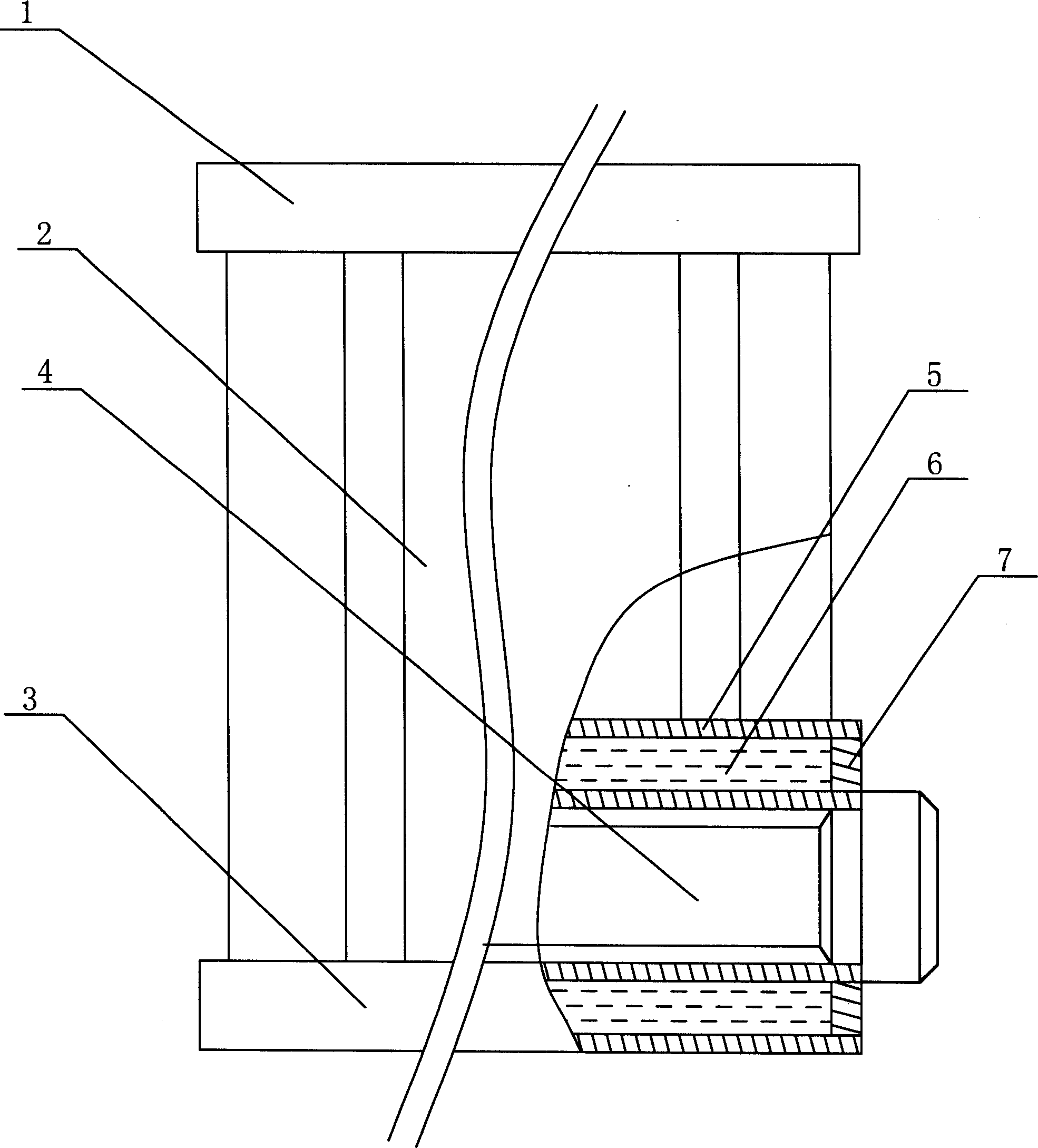

Image

Examples

Embodiment 1

[0021] The raw material composition of the working medium of the superconducting medium radiator is: double distilled water 1000g, copper sulfate 20g, potassium sulfate 17g, chromic anhydride 9g, ethanol or acetone 200g, potassium permanganate 0.5g.

Embodiment 2

[0023] The raw materials of the working medium of the superconducting medium radiator are: 1000g of double distilled water, 25g of copper sulfate, 22g of potassium sulfate, 14g of chromic anhydride, 450g of ethanol or acetone, and 1g of potassium permanganate. All the other are with embodiment 1.

Embodiment 3

[0025] The raw material composition of the working medium of the superconducting dielectric radiator is: double distilled water 1000g, copper sulfate 30, potassium sulfate 27g, chromic anhydride 19g, ethanol or acetone 700g, potassium permanganate 2g. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com